Method for preparing dextrorotatory oxiracetam oral fast dissolving films by hot-melt extrusion

A technology of dextropiridamide and oral instant film, which is applied in the field of preparation of dexoxypyramide oral instant film by hot-melt extrusion, can solve the problem of difficult control of disintegration time and tensile strength, Restrict the development and application of oral instant film, low drug loading, etc., to achieve the effect of improving bioavailability, avoiding elimination effect, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

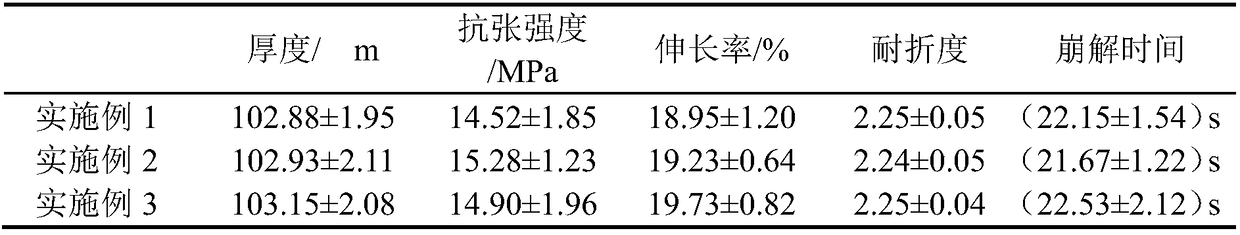

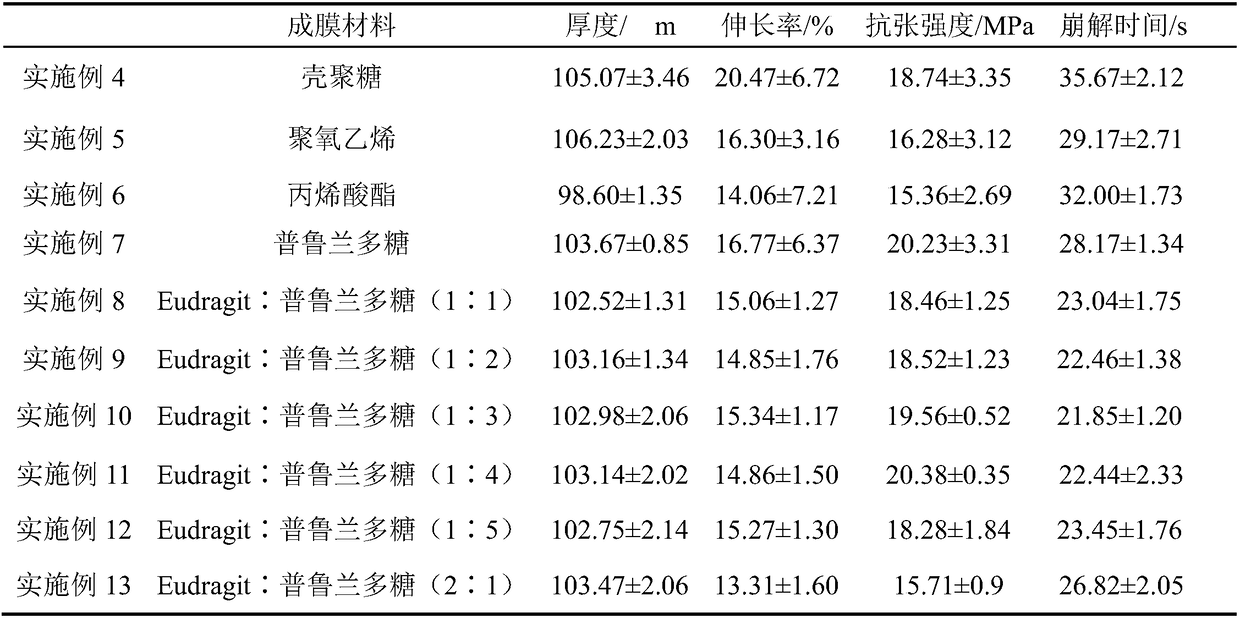

Embodiment 1

[0028] Mix 39 parts of dextropyridine, 8 parts of acrylate, 32 parts of pullulan, 10 parts of glycerol triacetate, 10 parts of pregelatinized starch, and 1 part of fructose. The feeding area of the film machine is sent to the hot melting area, where it is melted at 81-83 ° C, and the molten mixture is continuously output through the metering area, poured into the mold, and forms a film after cooling.

Embodiment 2

[0030]Mix 25 parts of dextropyridine, 18 parts of acrylate, 36 parts of pullulan, 10 parts of glycerol triacetate, 10 parts of low-substituted hydroxypropyl cellulose, and 1 part of xylitol, and mix well , sent to the hot-melt zone through the feeding zone of the hot-melt film laminator, hot-melted at 70-72°C, the molten mixture is continuously output through the metering zone, poured into the mold, and forms a film after cooling.

Embodiment 3

[0032] Mix 55 parts of D-hydroxypyridine, 10 parts of acrylate, 20 parts of pullulan, 7 parts of triethyl citrate, 7 parts of low-substituted hydroxypropyl cellulose, and 1 part of aspartame, After mixing evenly, it is sent to the hot-melt zone through the feed zone of the hot-melt film laminator, and melted at 95-98°C. The molten mixture is continuously output through the metering zone, poured into the mold, and forms a film after cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com