Controlled-release type scar repairing and beautifying gel material and preparation method

A gel material and scar technology, applied in the field of medical cosmetology, can solve problems such as poor controllability, poor scar repair effect, and difficulty in effectively restoring metabolic function, and achieves good controlled release effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

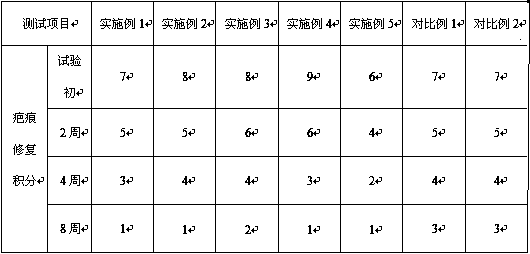

Examples

Embodiment 1

[0029] a. Disperse commercially available TGC protease in graphene airgel, freeze-dry, and stably encapsulate TGC protease;

[0030] b. Add fatty alcohol polyoxyethylene ether and alkyl glycoside, and ultrasonically disperse evenly;

[0031] c. It is further mixed with chitosan, acrylic acid, collagen, and azone to make a jelly, which is a controlled-release scar repairing cosmetic gel material.

[0032] The freeze-drying temperature is -20°C.

[0033] The ultrasonic frequency of ultrasonic dispersion is 100kHz, and the power density is 0.8W / cm 2 , the dispersion time is 20min.

[0034] Among the raw materials, 4 parts by weight of TGC protease, 5 parts by weight of graphene airgel, 5 parts by weight of fatty alcohol polyoxyethylene ether, 4 parts by weight of alkyl glycoside, 10 parts by weight of chitosan, 12 parts by weight of acrylic acid, collagen 57 parts by weight, 3 parts by weight of azone.

Embodiment 2

[0036] a. Disperse commercially available TGC protease in graphene airgel, freeze-dry, and stably encapsulate TGC protease;

[0037] b. Add fatty alcohol polyoxyethylene ether and alkyl glycoside, and ultrasonically disperse evenly;

[0038] c. It is further mixed with chitosan, acrylic acid, collagen, and azone to make a jelly, which is a controlled-release scar repairing cosmetic gel material.

[0039] The freeze-drying temperature is -10°C.

[0040] The ultrasonic frequency of ultrasonic dispersion is 70kHz, and the power density is 0.6W / cm 2 , The dispersion time is 40min.

[0041]Among the raw materials, 2 parts by weight of TGC protease, 8 parts by weight of graphene airgel, 5 parts by weight of fatty alcohol polyoxyethylene ether, 4 parts by weight of alkyl glycoside, 5 parts by weight of chitosan, 15 parts by weight of acrylic acid, collagen 60 parts by weight, 1 part by weight of azone.

Embodiment 3

[0043] a. Disperse commercially available TGC protease in graphene airgel, freeze-dry, and stably encapsulate TGC protease;

[0044] b. Add fatty alcohol polyoxyethylene ether and alkyl glycoside, and ultrasonically disperse evenly;

[0045] c. It is further mixed with chitosan, acrylic acid, collagen, and azone to make a jelly, which is a controlled-release scar repairing cosmetic gel material.

[0046] The freeze-drying temperature is -15°C.

[0047] The ultrasonic frequency of ultrasonic dispersion is 70kHz, and the power density is 0.7W / cm 2 , The dispersion time is 30min.

[0048] Among the raw materials, 3 parts by weight of TGC protease, 7 parts by weight of graphene airgel, 5 parts by weight of fatty alcohol polyoxyethylene ether, 2 parts by weight of alkyl glycoside, 5 parts by weight of chitosan, 12 parts by weight of acrylic acid, collagen 63 parts by weight, 3 parts by weight of azone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com