Mobile phone lens and production process thereof

A production process and lens technology, which is applied in the field of mobile phone lenses and its production process, can solve the problems of increased labor and factory use costs, low surface hardness of mobile phone lenses, and poor quality of finished products, so as to achieve good protection and save process steps , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

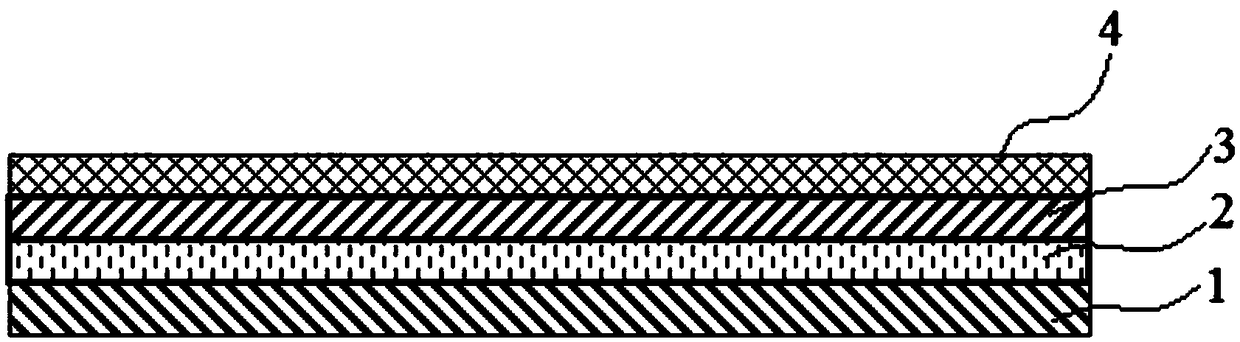

[0028] This embodiment provides a mobile phone lens, such as figure 1 As shown, from bottom to top (along the direction away from the mobile phone), it includes a PC layer 1 (polycarbonate layer), an ink pattern layer 2, an adhesive layer 3 and a PET layer 4 (polyethylene terephthalate layer) that are sequentially stacked. Glycol ester layer), wherein, the PC layer 1 is a substrate layer with a thickness of 0.4mm, the ink pattern layer 2 is a color layer made according to the design pattern through a silk screen printing process, and the adhesive layer 3 is composed of It is coated with ultraviolet light curing glue (UV glue), which is used to bond the PC layer 1 and the PET layer 4 together. The thickness of the coating is 10 μm, and the solid content of the UV glue used is 80-100%. This implementation In the example, it is 80%, its viscosity is 1000cps, and it can be cured under ultraviolet LED cold light source. It has no pollution to the environment, no solvent, low flamma...

Embodiment 2

[0037] This embodiment provides a mobile phone lens, such as figure 1 As shown, from bottom to top (along the direction away from the mobile phone), it includes a PC layer 1 (polycarbonate layer), an ink pattern layer 2, an adhesive layer 3 and a PET layer 4 (polyethylene terephthalate layer) that are sequentially stacked. Glycol ester layer), wherein, the PC layer 1 is a substrate layer with a thickness of 0.6mm, the ink pattern layer 2 is a color layer made according to the design pattern through a silk screen printing process, and the adhesive layer 3 is composed of It is coated with ultraviolet light curing glue (UV glue), which is used to bond the PC layer 1 and the PET layer 4 together. The thickness of the coating is 20 μm, and the solid content of the UV glue used is 80-100%. This implementation In the example, it is 100%, its viscosity is 2000cps, and it can be cured under ultraviolet LED cold light source. It has no pollution to the environment, no solvent, low flamm...

Embodiment 3

[0040] This embodiment provides a mobile phone lens, such as figure 1As shown, from bottom to top (along the direction away from the mobile phone), it includes a PC layer 1 (polycarbonate layer), an ink pattern layer 2, an adhesive layer 3 and a PET layer 4 (polyethylene terephthalate layer) that are sequentially stacked. Glycol ester layer), wherein, the PC layer 1 is a substrate layer with a thickness of 0.5mm, the ink pattern layer 2 is a color layer made according to a design pattern through a silk screen printing process, and the adhesive layer 3 is composed of It is coated with ultraviolet light curing glue (UV glue), which is used to bond the PC layer 1 and the PET layer 4 together. The thickness of the coating is 15 μm, and the solid content of the UV glue used is 80-100%. This implementation In the example, it is 90%, its viscosity is 1500cps, and it can be cured under ultraviolet LED cold light source. It has no pollution to the environment, no solvent, low flammabil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com