Preparation method of silicon dioxide aerogel

A silicon dioxide and aerogel technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve problems such as unfavorable large-scale production, achieve large-scale promotion and application, improve environmental adaptability, reduce The effect of production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

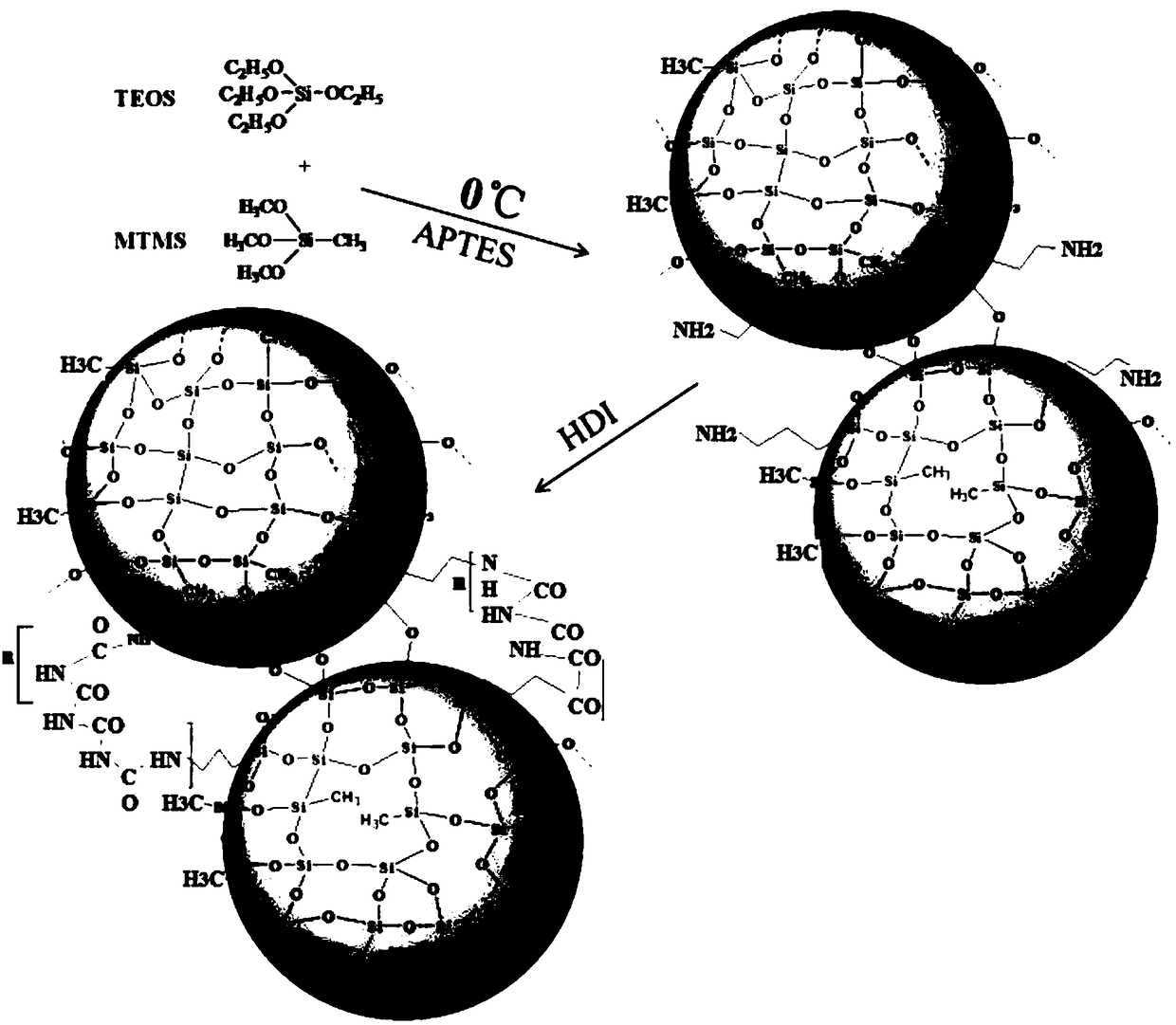

Method used

Image

Examples

Embodiment 1

[0031] Preparation of silica airgel with a molar ratio of MTMS:TEOS:APTES=1:1:1 at 0°C includes the following steps:

[0032] (1) Measure 11.2ml, 7.2ml, and 11.7ml of ethyl orthosilicate, methyltrimethoxysilane, and 3-aminopropyltriethoxysilane respectively, place them in container a, stir at room temperature for 100min, and obtain a mixture Reagent A: Measure 50ml and 12.5ml of acetonitrile and deionized water respectively, place them in container b, stir at room temperature for 60min, and obtain mixed reagent B;

[0033] (2) Place container a and container b in ice water respectively until the temperature of mixed reagent A and mixed reagent B therein drops to 0°C;

[0034] (3) Quickly pour the cooled mixed reagent B into mixed reagent A, first stir at 0°C for 3 minutes to complete the gelation; then pour the gelled solution into the pre-prepared mold for aging for 24 hours, wet gel;

[0035] (4) Place the obtained wet gel successively in an ethanol solution with a volume ...

Embodiment 2

[0039] Preparation of silica airgel with a molar ratio of MTMS:TEOS:APTES=7:1:4 at 0°C includes the following steps:

[0040] (1) Measure 11.2ml, 50.4ml, and 47ml of ethyl orthosilicate, methyltrimethoxysilane, and 3-aminopropyltriethoxysilane respectively, place them in container a, stir at room temperature for 100min, and obtain a mixed reagent A: Measure 50ml and 15ml of acetonitrile and deionized water respectively, place them in container b, and stir at room temperature for 40min to obtain mixed reagent B;

[0041] (2) Place container a and container b in ice water respectively until the temperature of mixed reagent A and mixed reagent B therein drops to 0°C;

[0042] (3) Quickly pour the cooled mixed reagent B into the mixed reagent A, first stir at 0°C for 10 minutes to complete the gelation; then pour the gelled solution into the pre-prepared mold for aging for 30 hours, wet gel;

[0043] (4) Place the obtained wet gel successively in an ethanol solution with a volum...

Embodiment 3

[0047] Preparation of silica airgel with a molar ratio of MTMS:TEOS:APTES=4:1:1 at 0°C includes the following steps:

[0048](1) Measure 8.9ml, 28.8ml, and 11.7ml of ethyl orthosilicate, methyltrimethoxysilane, and 3-aminopropyltriethoxysilane respectively, place them in container a, stir at room temperature for 95min, and obtain a mixture Reagent A: Measure 50ml and 13.5ml of acetonitrile and deionized water respectively, place them in container b, stir at room temperature for 50min, and obtain mixed reagent B;

[0049] (2) Place container a and container b in ice water respectively until the temperature of mixed reagent A and mixed reagent B therein drops to 0°C;

[0050] (3) Quickly pour the cooled mixed reagent B into the mixed reagent A, first stir at 0°C for 8 minutes to complete the gelation; then pour the gelled solution into the pre-prepared mold for aging for 28 hours, wet gel;

[0051] (4) Place the obtained wet gel successively in an ethanol solution with a volum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com