Monodisperse polystyrene microspheres and preparation method and application thereof

A technology of polystyrene microspheres and polystyrene, applied in the direction of microsphere preparation, microcapsule preparation, etc., can solve the problem of reducing the water resistance, solvent resistance and mechanical properties of polymer products, expensive emulsifiers, and increasing product costs and other problems, to achieve the effects of strong controllability of particle size, low toxicity, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

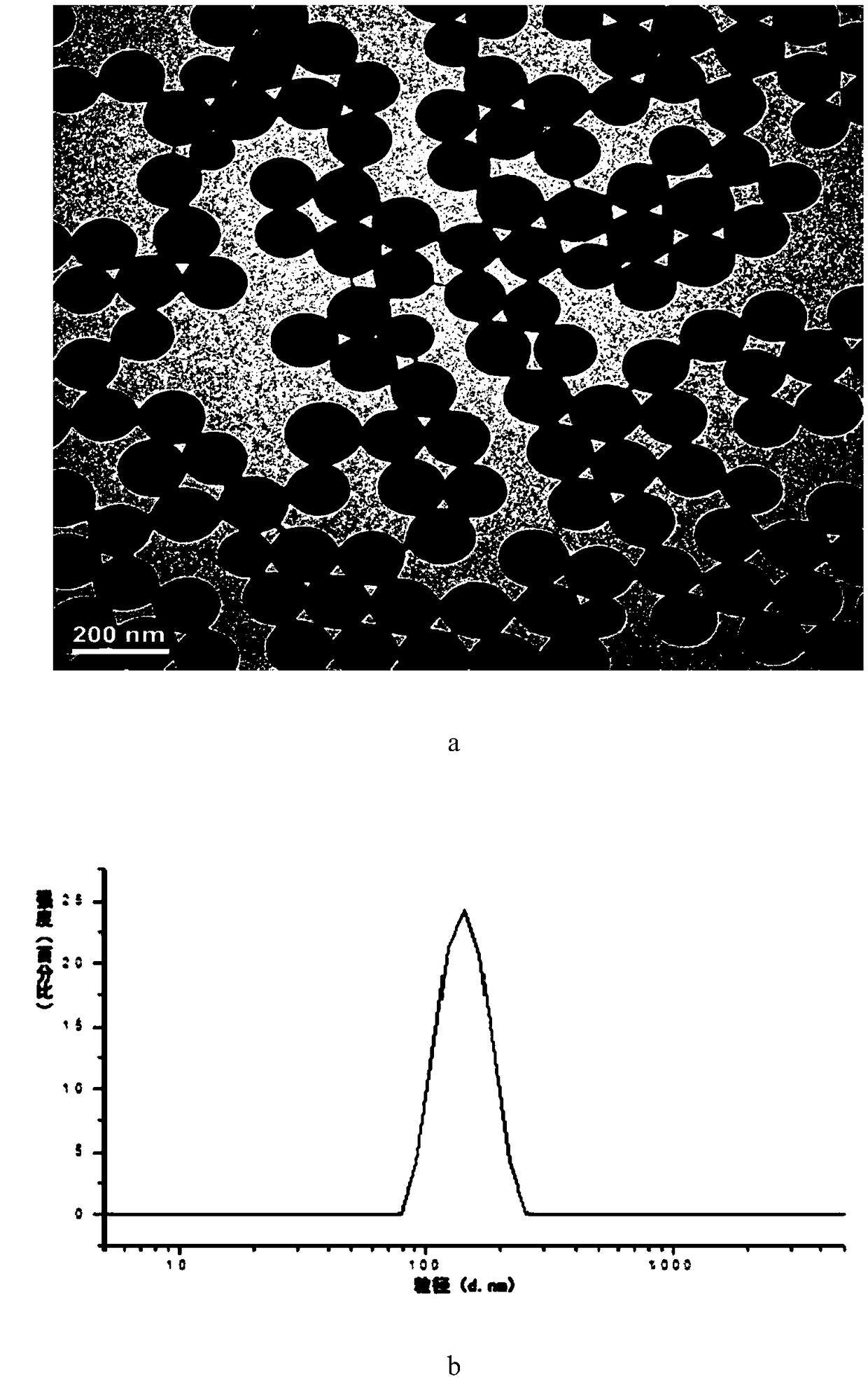

Embodiment 1

[0057] The method for preparing monodisperse polystyrene microspheres in this embodiment comprises the following steps:

[0058] Measure 4.6ml of purified styrene monomer and 100ml of double-distilled water into a 250mL three-necked flask, place the beaker in an ultrasonic instrument (set the ultrasonic power to 99%, and set the ultrasonic time to 30min), add methanol ( The selected methanol specification is analytically pure, content ≥ 99.7%) until the mixed solution becomes uniform, clear and transparent, and the recorded methanol is 175ml. Weigh 0.1013g of potassium persulfate solid powder into the beaker, place the beaker in a water bath, set the temperature to 70°C and turn on the magnetic stirring button (the stirring speed is suitable, ~300rmp), and the reaction time is controlled at 6-7 hours. After the reaction was completed, the steam was distilled for 1h. Under stirring, the emulsion is cooled naturally, and the target product can be obtained by centrifugation etha...

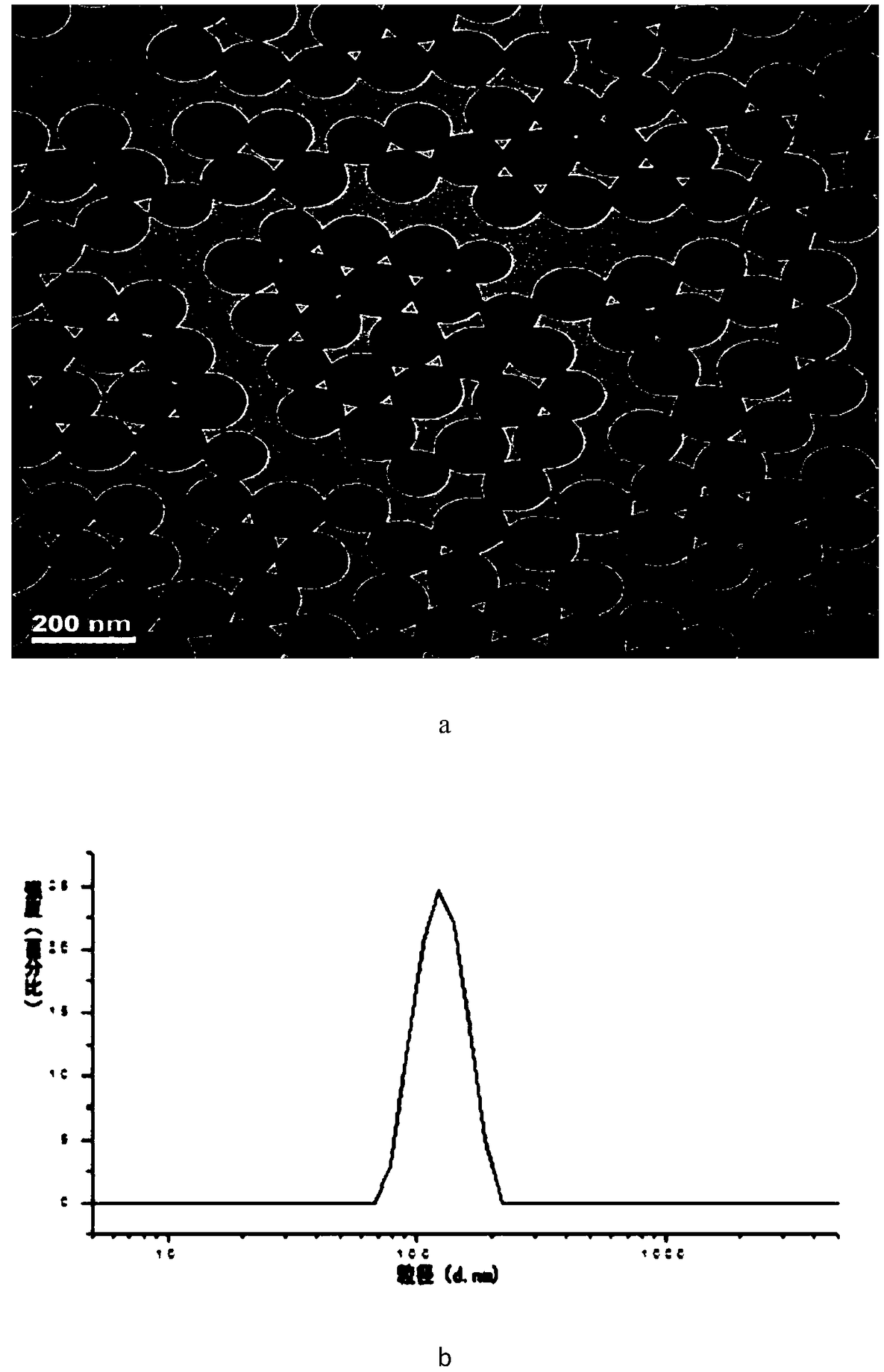

Embodiment 2

[0060] The method for preparing monodisperse polystyrene microspheres in this embodiment comprises the following steps:

[0061] Measure 4.6ml of purified styrene monomer and 100ml of double-distilled water into a 250mL three-necked flask, place the beaker in an ultrasonic instrument (set the ultrasonic power to 99%, and set the ultrasonic time to 30min), and add ethanol ( The selected ethanol specification is analytically pure, content ≥ 99.5%) until the mixed solution becomes uniform, clear and transparent, and the record ethanol is 120ml. Weigh 0.1124g of potassium persulfate solid powder and add it to the mixed solution, place the beaker in a water bath, set the temperature to 70°C and turn on the magnetic stirring button (the stirring speed is suitable, ~300rmp), and the reaction time is controlled at 6-7 hours. After the reaction was completed, the steam was distilled for 1h. Under stirring, the emulsion is cooled naturally, and the target product can be obtained by cen...

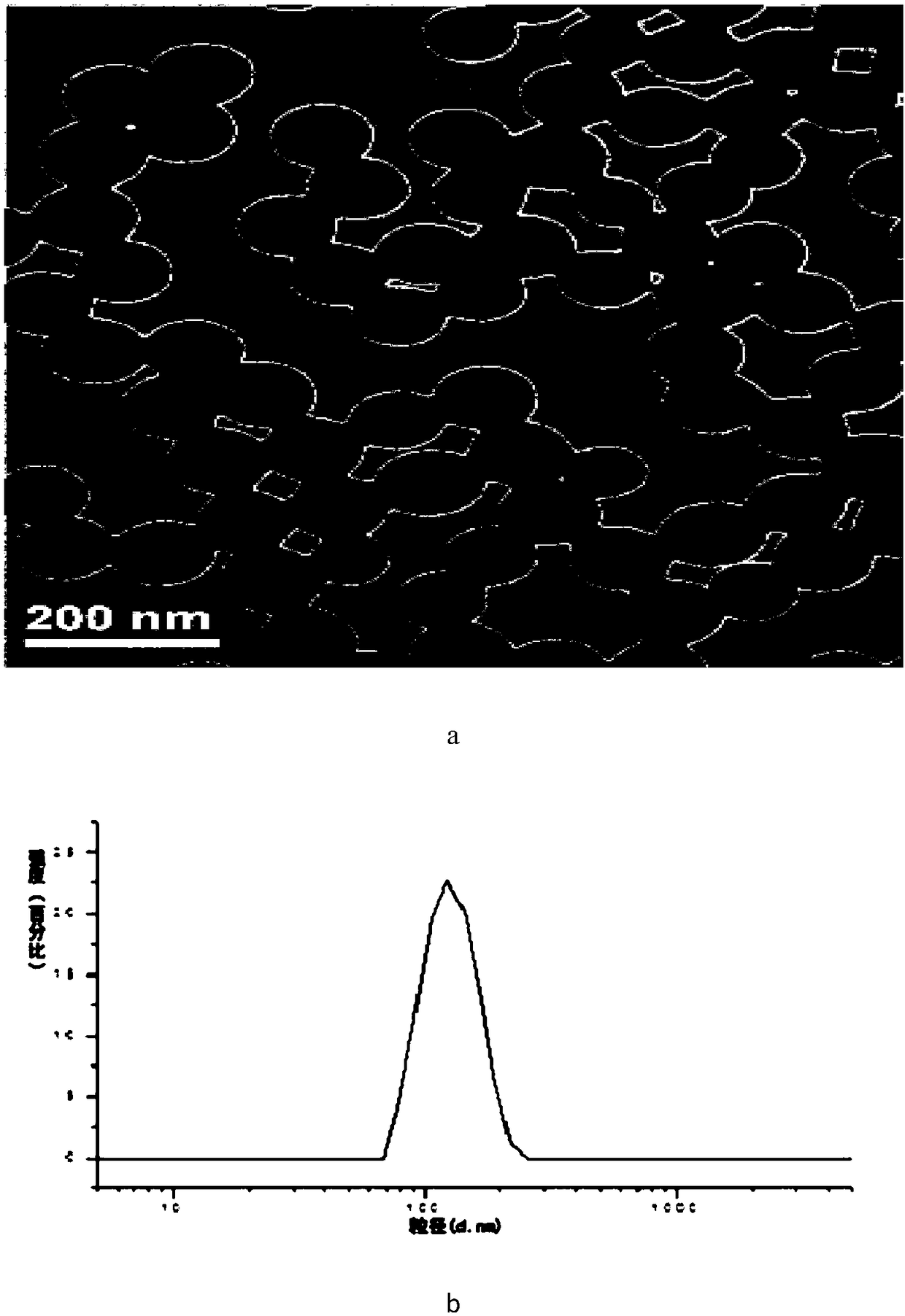

Embodiment 3

[0063] The method for preparing monodisperse polystyrene microspheres in this embodiment comprises the following steps:

[0064] Measure 4.6ml of purified styrene monomer and 100ml of double-distilled water into a 250mL three-necked flask, place the beaker in an ultrasonic instrument (set the ultrasonic power to 99%, and set the ultrasonic time to 30min), and add isopropyl Alcohol (the selected isopropanol specification is analytically pure, content ≥ 99.7%) until the mixed solution becomes uniform, clear and transparent, and the record isopropanol is 90ml. Weigh 0.1052g of potassium persulfate solid powder and add it to the mixed solution, place the beaker in a water bath, set the temperature to 70°C and turn on the magnetic stirring button (the stirring speed is suitable, ~300rmp), and the reaction time is controlled at 6-7 hours. After the reaction was completed, the steam was distilled for 1h. Under stirring, the emulsion is cooled naturally, and the target product can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com