Preparation method of nickel ion modified covalent organic framework material and application thereof

A technology of covalent organic framework and nickel ions, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, carbon monoxide, etc., can solve the problem of low product selectivity, and achieve simple operation and moderate price , the effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

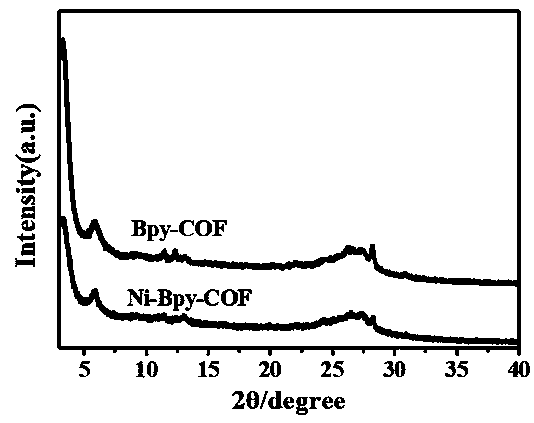

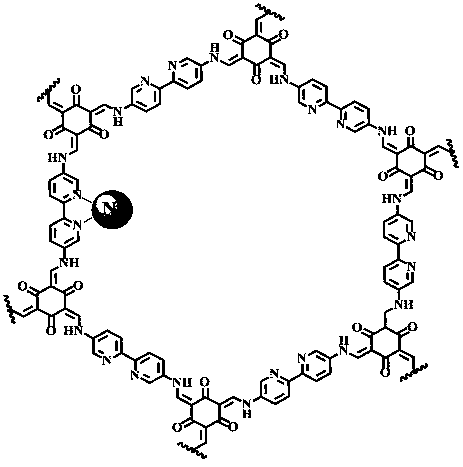

[0028]5,5'-diamino-2,2'-bipyridine and 2,4,6-trihydroxy-1,3,5-benzenetricarbaldehyde were synthesized by solvothermal method to Bpy-COF containing bipyridine group, The mass ratio of 5,5'-diamino-2,2'-bipyridine to 2,4,6-trihydroxy-1,3,5-benzenetricarbaldehyde is 9.3:7, and the process parameters of the solvothermal method are : The reaction temperature is 120°C, and the reaction time is 72h. Then the obtained Bpy-COF and nickel perchlorate were added into 30ml of acetonitrile solvent at a mass ratio of 2:1, stirred at room temperature for 4h, then centrifuged and washed 5 times with a large amount of acetonitrile solvent, and dried in vacuum at 70°C for 12h. The obtained nickel ion-modified covalent organic framework catalyst Ni-Bpy-COF. Such as figure 1 , 2 , 3, and 4 show the XRD pattern of the prepared Ni-Bpy-COF, the structure diagram of Ni-Bpy-COF, the SEM diagram of Ni-Bpy-COF and the FTIR diagram of Ni-Bpy-COF.

Embodiment 2

[0030] 5,5'-diamino-2,2'-bipyridine and 2,4,6-trihydroxy-1,3,5-benzenetricarbaldehyde were synthesized by solvothermal method to Bpy-COF containing bipyridine group, The mass ratio of 5,5'-diamino-2,2'-bipyridine to 2,4,6-trihydroxy-1,3,5-benzenetricarbaldehyde is 9.3:7, and the process parameters of the solvothermal method are : The reaction temperature is 120°C, and the reaction time is 120h. Then the obtained Bpy-COF and nickel perchlorate were added into a certain amount of 30ml of acetonitrile solvent at a mass ratio of 1:1, stirred at room temperature for 6 hours, then centrifuged and washed 3 times with a large amount of acetonitrile solvent, and vacuum-dried at 70°C 12h, the obtained nickel ion modified covalent organic framework catalyst Ni-Bpy-COF.

Embodiment 3

[0032] 5,5'-diamino-2,2'-bipyridine and 2,4,6-trihydroxy-1,3,5-benzenetricarbaldehyde were synthesized by solvothermal method to Bpy-COF containing bipyridine group, The mass ratio of 5,5'-diamino-2,2'-bipyridine to 2,4,6-trihydroxy-1,3,5-benzenetricarbaldehyde is 9.3:7, and the process parameters of the solvothermal method are : The reaction temperature is 120° C., and the reaction time is 100 h. Then the obtained Bpy-COF and nickel perchlorate were added to a certain amount of 30ml acetonitrile solvent according to the mass ratio of 2:1, stirred at room temperature for 5h, then centrifuged and washed 4 times with a large amount of acetonitrile solvent, and dried in vacuum at 70°C 12h, the obtained nickel ion modified covalent organic framework catalyst Ni-Bpy-COF.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com