A method for promoting the hydrolysis of polysaccharides containing glycosidic bonds under photothermal conditions

A technology of glycosidic bonds and conditions, which is applied in the production of sugar, chemical instruments and methods, organic chemistry, etc., can solve the problems of high production cost, high equipment requirements, low catalyst activity, etc., achieve weak corrosion of equipment, improve efficiency, Ease of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Preparation of 3%Ir / HY Catalyst

[0020] 1g carrier added carrier weight ratio 3%H 2 IrCl 6 The ethanol solution was stirred and evaporated to dryness at 80°C, then placed in an oven at 80°C for 12 hours, and then lowered to room temperature. Then in air atmosphere at 5°C·min -1 The rate was raised to 500°C, fired for 2h, and then lowered to room temperature. Then, under hydrogen atmosphere, at 5°C·min -1 Heating rate to 500 ℃, keep 2h.

Embodiment 2

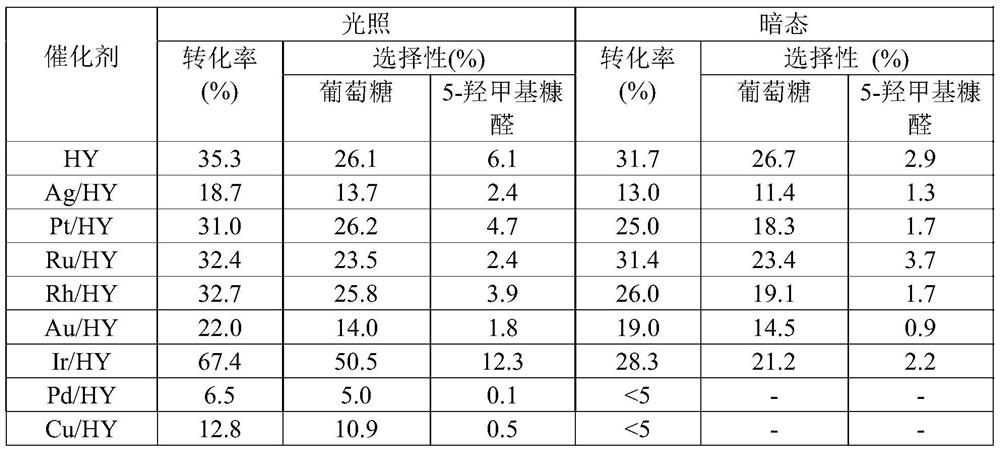

[0022] The selectivity and conversion rate of the reaction using the Ir / HY catalyst base prepared in Example 1 to convert cellobiose under light and dark conditions are as follows:

[0023] Add 50mg of cellobiose to 4.5g of 1-ethyl-3-methylimidazolium chloride, heat at 100°C for 1h to dissolve all the cellobiose in 1-ethyl-3-methylimidazolium chloride, then add 50mg of catalyst and 0.45 mL of water. Use xenon light to illuminate and heat at 100°C for 8h, and the wavelength of illumination is 420-700nm. Finally, the material composition and content of the liquid phase were analyzed by liquid chromatography. In the dark condition, except that no light is given, the other operation steps are the same as the light condition. The evaluation of selectivity and conversion rate is shown in Table 1.

Embodiment 3

[0025] Preparation of 3%Au / HY Catalyst

[0026] 1g carrier added carrier weight ratio 3% HAuCl 4 The aqueous solution was stirred and evaporated to dryness at 80°C, then placed in an oven at 80°C for 12 hours, and then lowered to room temperature. Under air atmosphere at 5°C·min -1 The rate was raised to 500°C, fired for 2h, and then lowered to room temperature. Then, under hydrogen atmosphere, at 5°C·min -1 Heating rate to 500 ℃, keep 2h.

[0027] The selectivity and conversion rate of the conversion reaction of cellobiose using Au / HY catalyst under light and dark conditions were operated as follows:

[0028] Add 50mg of cellobiose to 4.5g of 1-ethyl-3-methylimidazolium chloride, heat at 100°C for 1h to dissolve all the cellobiose in 1-ethyl-3-methylimidazolium chloride, then add 50mg of catalyst and 0.45 mL of water. Use xenon light to illuminate and heat at 100°C for 8h, and the wavelength of illumination is 420-700nm. Finally, the material composition and content of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com