A kind of high wear-resistant liner and its preparation method

A high wear-resistant and lining technology, applied in the field of wear-resistant materials, can solve the problems of inability to play a wear-resistant role, uneven distribution of through holes, and decreased use effect, and achieves improvement, reinforcement, and resistance to wear. Effects of improved impact toughness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

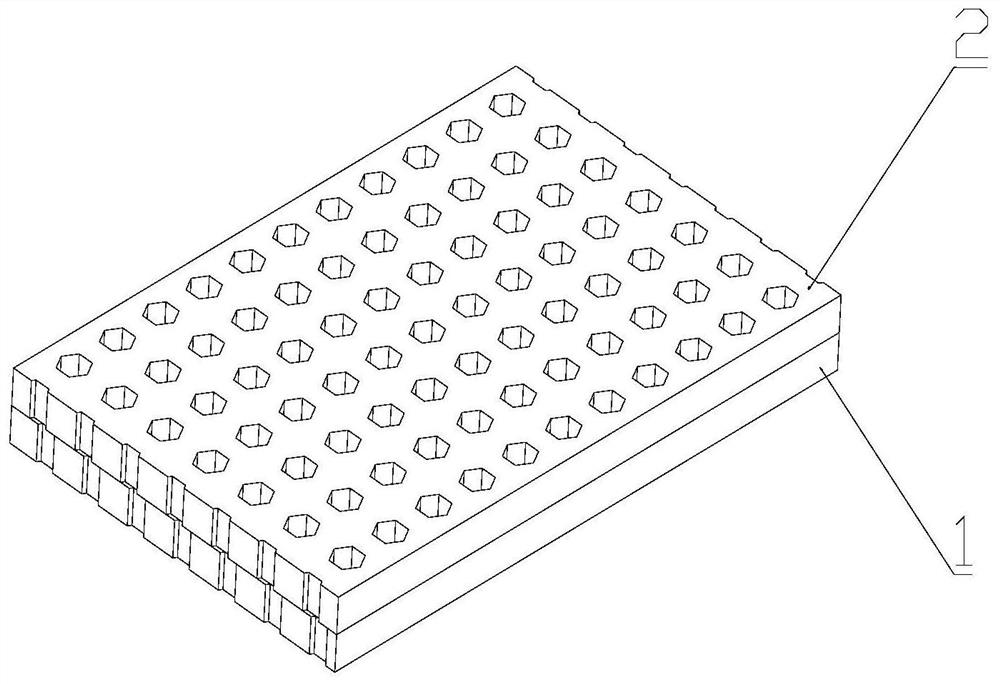

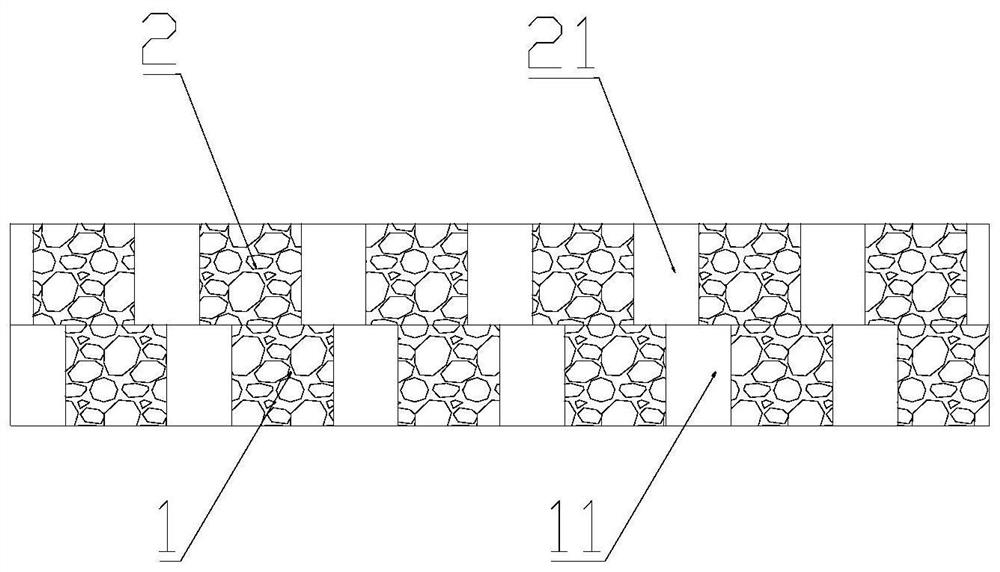

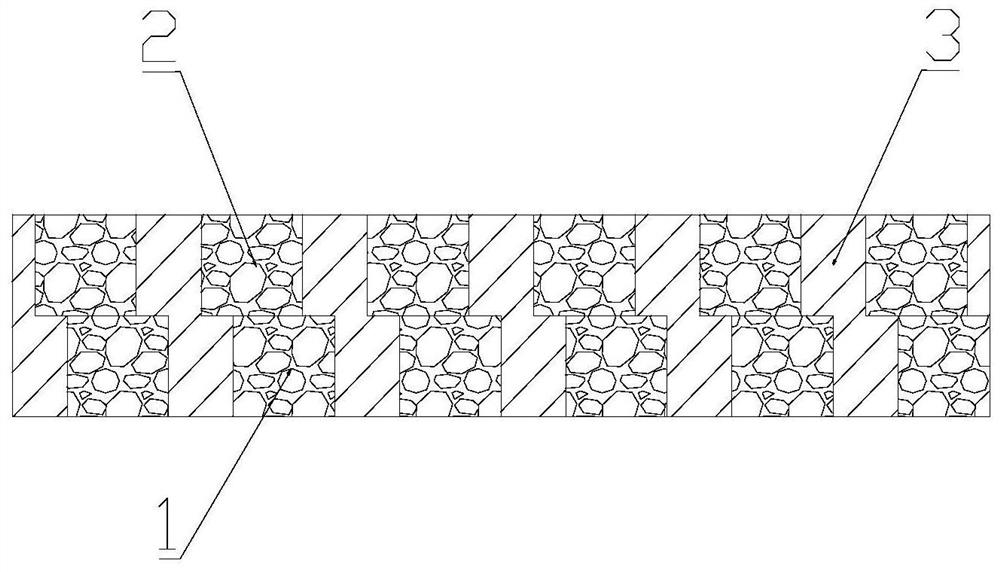

[0035] Such as figure 1 , figure 2 , image 3 As shown, a high wear-resistant liner includes a porous ceramic matrix and a metal matrix 3 filled in the pores of the porous ceramic matrix. The porous ceramic matrix is composed of the first porous ceramic plate 1 and the first porous ceramic plate 1 above the second porous ceramic plate 2, the first porous ceramic plate 1 is provided with a number of regular polygonal first casting through holes 11, the second porous ceramic plate 2 is provided with a number of A regular polygonal second pouring through hole 21, the second pouring through hole 21 forms a partial shield for each first pouring through hole 11. The high wear-resistant liner of the present invention organically combines the toughness and bending resistance of metal with the high wear resistance, high strength and oxidation resistance of ceramics, and the overall strength, impact toughness and wear resistance are all greatly improved. The first pouring through ...

Embodiment 2

[0044] A method for preparing a high wear-resistant liner, comprising the following steps:

[0045] S1, in parts by mass, weighed with a density of 3.2g / cm 3 , 50 parts of silicon carbide ceramic particles with an average particle size of 0.1mm and a density of 3.2g / cm 3 1. 50 parts of silicon nitride ceramic particles with an average particle diameter of 500um, 10 parts of titanium nitride with a submicron average particle diameter of 600nm, and 8 parts of phenolic liquid resin, put into a container and mix uniformly to obtain a mixed material;

[0046] S2, pouring the mixed material into different molds for molding to obtain preform A and preform B;

[0047] S3, put preform A and preform B into an atmosphere furnace, sinter at 1200°C for 40 minutes, keep warm at 980°C for 5 hours, after leaving the furnace and air-cool, hold at 250°C for 6 hours, and cool in the furnace. The first porous ceramic plate 1 and the second porous ceramic plate 2;

[0048] S4, after polishing t...

Embodiment 3

[0050] A method for preparing a high wear-resistant liner, comprising the following steps:

[0051] S1, by mass parts, weighed density is 3.25g / cm 3 , 45 parts of silicon carbide ceramic particles with an average particle size of 0.1mm and a density of 3.2g / cm 3 55 parts of silicon nitride ceramic particles with an average particle diameter of 500um, 20 parts of titanium nitride with a submicron average particle diameter of 600nm, and 14 parts of epoxy resin, put into a container and mix uniformly to obtain a mixed material;

[0052] S2, pouring the mixed material into different molds for molding to obtain preform A and preform B;

[0053] S3, put preform A and preform B into an atmosphere furnace, sinter at 1250°C for 35 minutes, keep warm at 1000°C for 2 hours, after leaving the furnace and air-cool, hold at 300°C for 2 hours, and cool in the furnace. The first porous ceramic plate 1 and the second porous ceramic plate 2;

[0054] S4, after polishing the first porous cera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com