Boiler continuous blowdown wastewater waste heat utilization system and method

A continuous row, boiler technology, applied in steam boilers, preheating, supplementary water supply, etc., can solve the problems of high energy consumption and high investment, and achieve the effects of long service life, improved thermal efficiency, and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

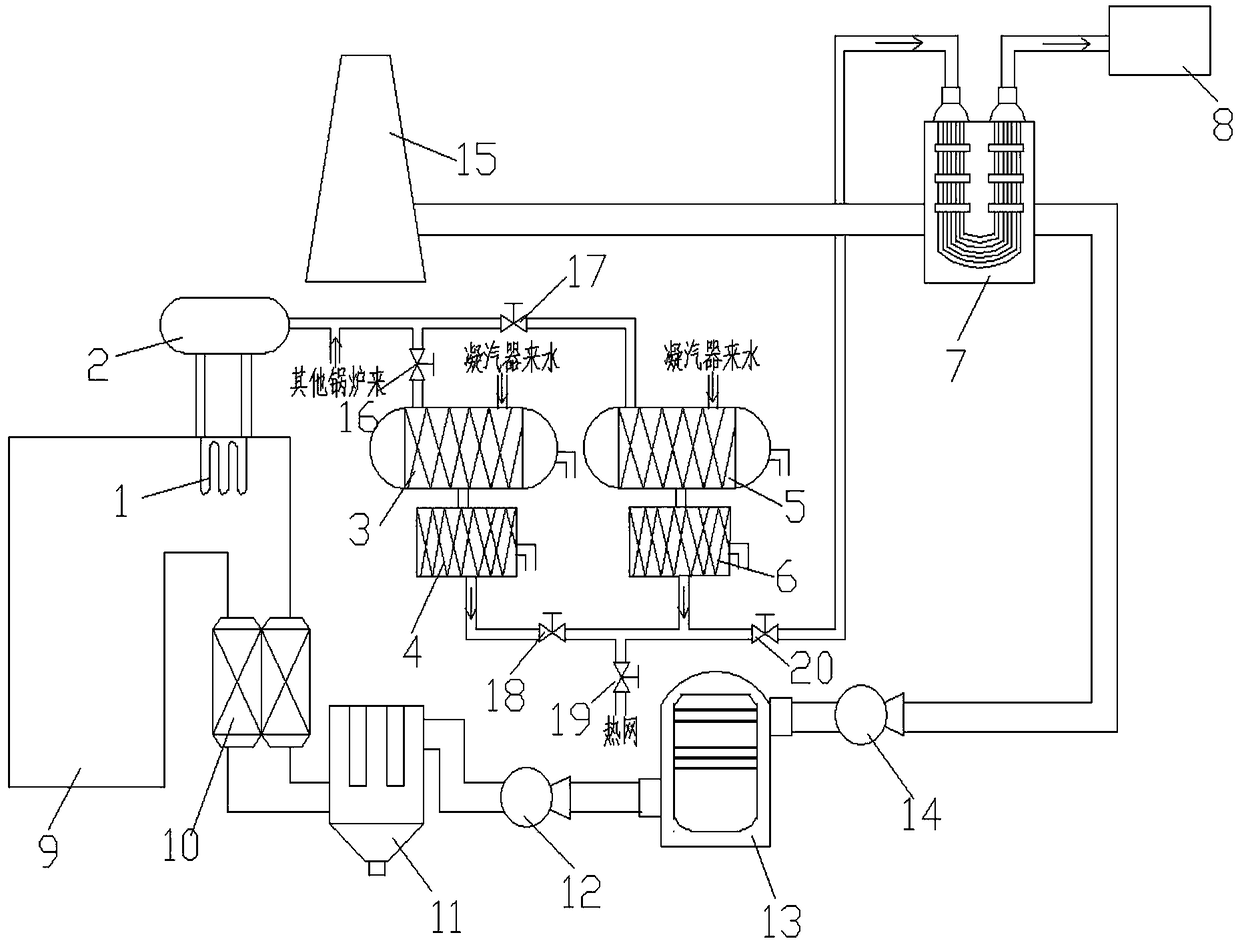

Embodiment 1

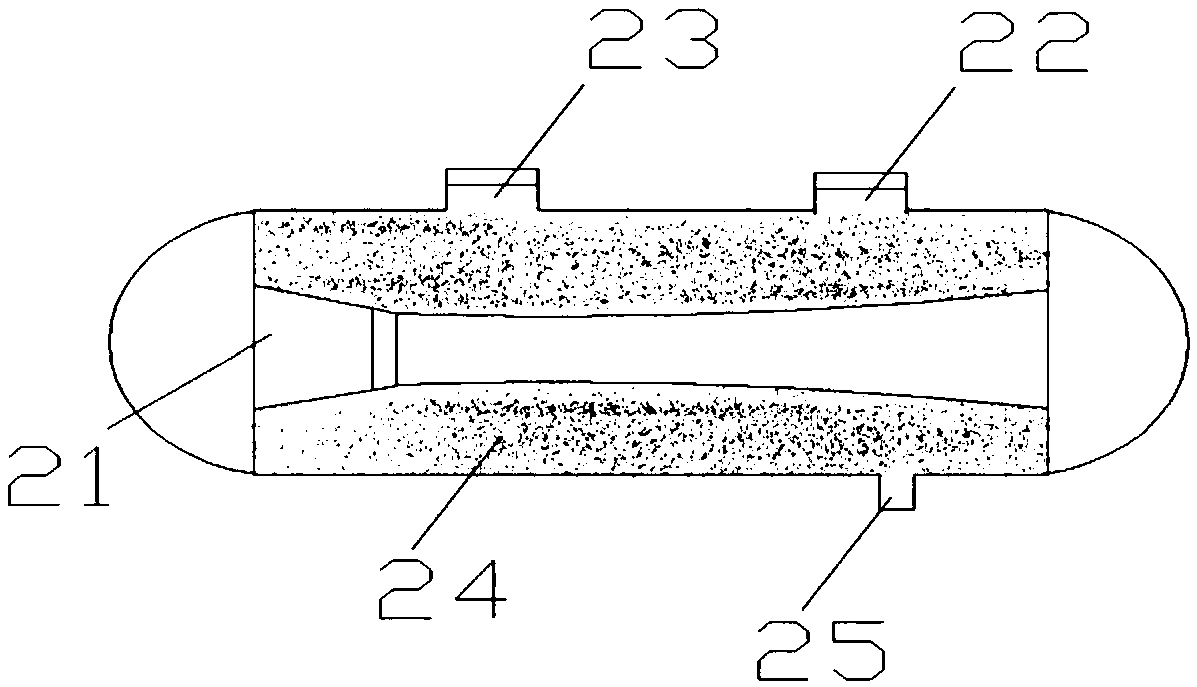

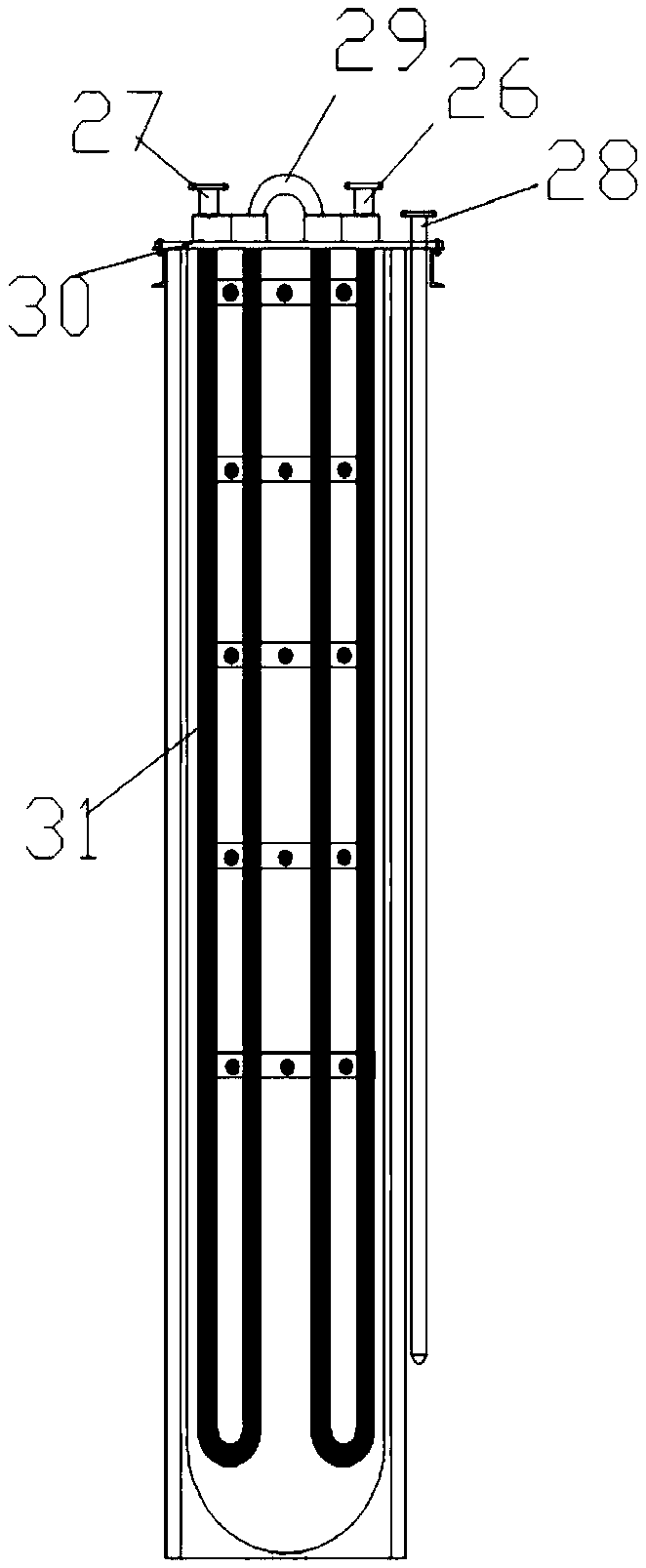

[0030] A boiler waste water waste heat utilization system, comprising a steam drum 2, a boiler 9 (equipped with a high-temperature economizer 1), an air preheater 10, a dry dust collector 11, a first induced draft fan 12, and a wet desulfurization tower 13 , the second induced draft fan 14, the flue gas reheater 7 (a group of heat exchange modules are provided, the heat exchange modules are made of composite material heat exchange tubes obtained by making fluoroplastic PFA film on the surface of the stainless steel base material, and the specifications of the stainless steel heat exchange tubes are φ10×1, fluorine plastic film thickness 0.5mm, external metal tube box sealed, heat exchange tubes arranged in U shape, staggered arrangement), desalted water tank 8 and chimney 15, outlet flue of boiler 9 and air preheater 10 The flue gas inlet of the air preheater 10 is connected to the flue gas inlet of the dry dust collector 11, the flue gas outlet of the dry dust collector 11 is ...

Embodiment 2

[0034] A boiler waste water waste heat utilization system, comprising a steam drum 2, a boiler 9 (equipped with a high-temperature economizer 1), an air preheater 10, a dry dust collector 11, a first induced draft fan 12, and a wet desulfurization tower 13 , the second induced draft fan 14, the flue gas reheater 7 (two groups of heat exchange modules are provided, the heat exchange modules are made of PTFE heat exchange tubes, and the PTFE heat exchange tube specifications are The heat exchange tubes are connected with the tube plate face plate 29 by welding technology, the tube plate face plate 29 is sealed with the external metal tube box, the heat exchange tubes are arranged in a U-shape, arranged in parallel), the desalinated water tank 8 and the chimney 15, the outlet smoke of the boiler 9 The duct is connected to the flue gas inlet of the air preheater 10, the flue gas outlet of the air preheater 10 is connected to the flue gas inlet of the dry dust collector 11, and the...

Embodiment 3

[0038]A boiler waste water waste heat utilization system, comprising a steam drum 2, a boiler 9 (equipped with a high-temperature economizer 1), an air preheater 10, a dry dust collector 11, a first induced draft fan 12, and a wet desulfurization tower 13 , the second induced draft fan 14, the flue gas reheater 7 (three groups of heat exchange modules are provided, the heat exchange modules are made of PTFE heat exchange tubes, the PTFE heat exchange tube specifications are φ10×1, and the heat exchange tubes adopt welding technology and The tube plate face plate 29 is connected, the tube plate face plate 29 is sealed with the external metal tube box, the heat exchange tubes are arranged in a U shape, and arranged in parallel), the desalted water tank 8 and the chimney 15, the outlet flue of the boiler 9 and the air preheater 10 The flue gas inlet of the air preheater 10 is connected to the flue gas inlet of the dry dust collector 11, the flue gas outlet of the dry dust collecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com