Preparation technology of low reflection infrared cutoff filter

A technology of infrared cut-off and optical filter, which is applied in the direction of optical filter, optical filter for photography, optics, etc., can solve the problem that the reflectivity of infrared cut-off filter cannot meet high-end products, etc., and achieve good effect of preparing finished products, The preparation scheme is simple and the effect of optimizing the ratio of the film system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

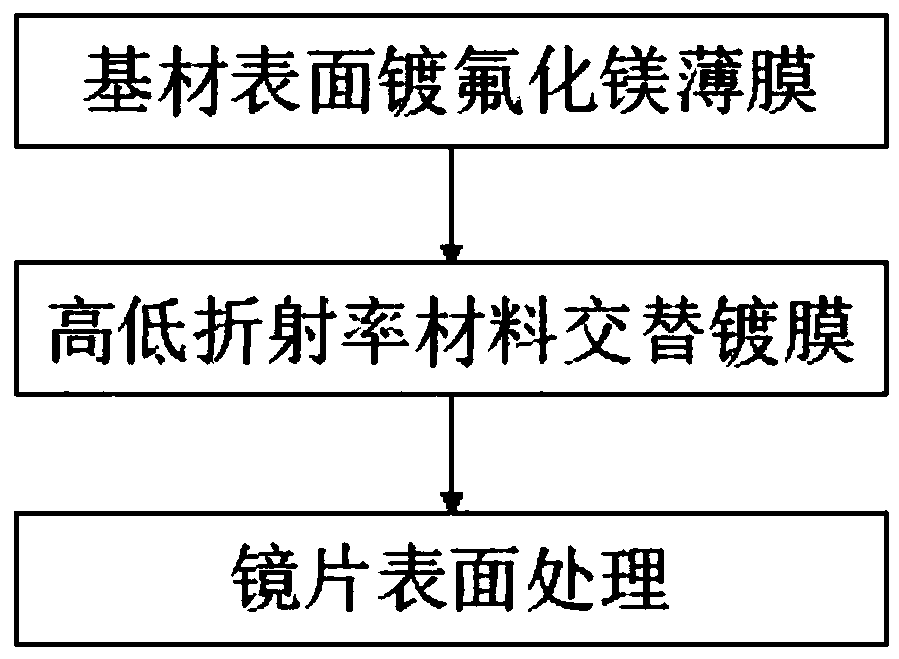

[0024] The concrete preparation steps of the preparation technology of this low-reflection infrared cut-off filter are as follows:

[0025] S1: Coating magnesium fluoride film on the surface of the substrate: Coating a magnesium fluoride film on the surface of the blue glass substrate by electron beam evaporation. The thickness of the magnesium fluoride film is 50nm±5nm. Magnesium fluoride film forming;

[0026] S2: Alternate coating of high and low refractive index materials: Silicon dioxide, a high refractive index material, and trititanium pentoxide, a low refractive index material, are alternately deposited in a vacuum state by electron beam evaporation in step S1 to coat a magnesium fluoride film On the final substrate, the alternate coating method achieves the purpose of selective transmission and reflection in the ultraviolet-near infrared band. The thickness of the high-refractive index material and the thickness of the low-refractive index material are 110nm±5nm and 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com