High-safety machining technology of samarium cobalt magnet

A high-safety, samarium-cobalt magnet technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of prolonged product release time, affecting production efficiency, long time, etc., to ensure product quality and safety, improve efficiency , Guarantee the effect of quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

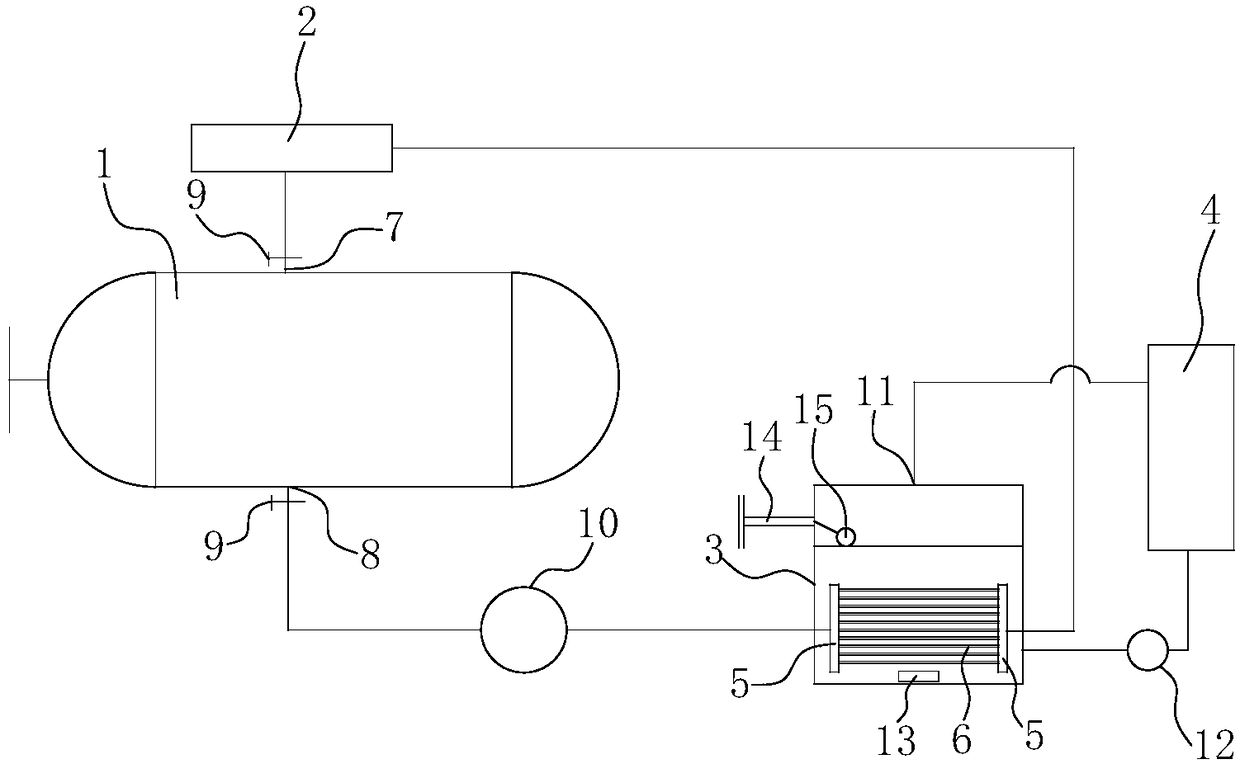

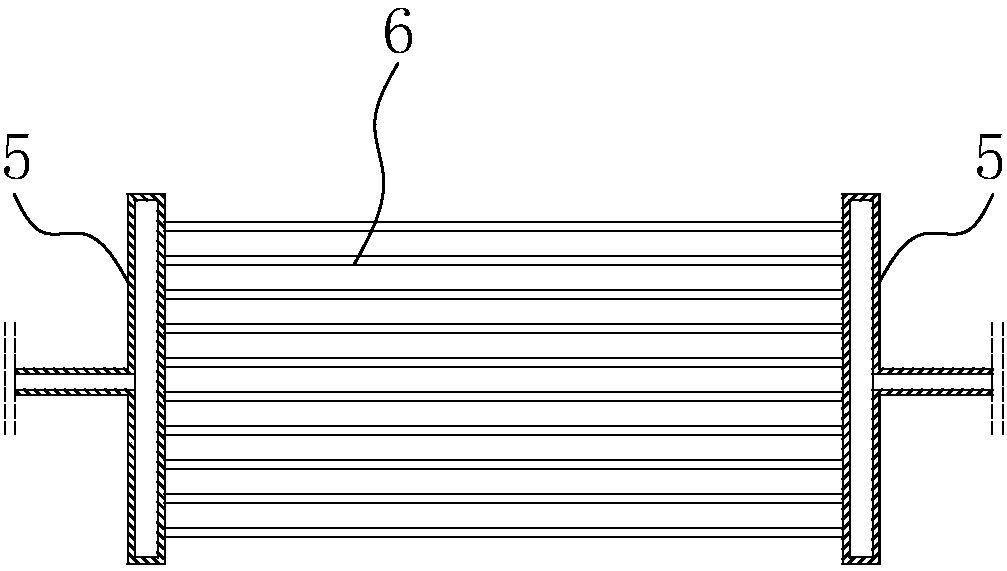

[0020] combine figure 1 and 2 As shown, the vacuum sintering machine used in the sintering process of the present invention includes a vacuum sintering furnace 1 and a cooling device for cooling the vacuum sintering furnace 1. The vacuum sintering furnace 1 is used for sintering NdFeB raw materials. The structure of the vacuum sintering furnace 1 is a prior art, and will not be repeated here. Such as figure 1 As shown, the cooling device includes a gas cylinder 2, a cooling water tank 3 and a condensation tank 4. The gas cylinder 2 is used to store inert gas, the cooling water tank 3 is used to store cooling water, and the condensation tank 4 is used to condense evaporated water. A heat exchange mechanism is provided in the cooling water tank 3, and the heat exchange mechanism may be a conventional heat exchange coil or other structures that play the same role.

[0021] In order to ensure the heat transfer performance of the heat transfer mechanism, a better approach is, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com