Positive electrode material used for lithium ion batteries and preparation method of positive electrode material

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor high voltage tolerance, insufficient safety performance, and low cycle stability, so as to reduce dissolution and improve cycle The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

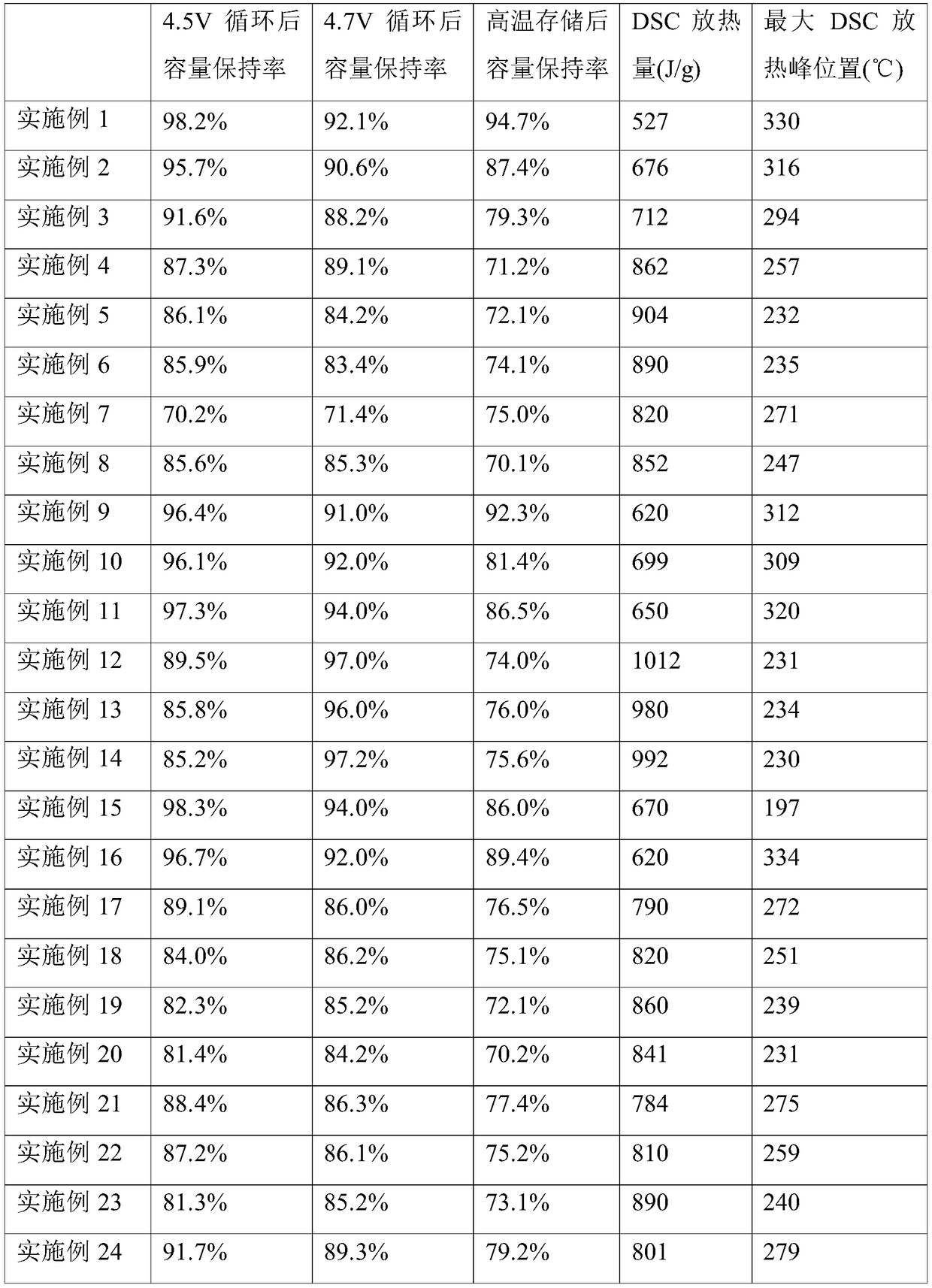

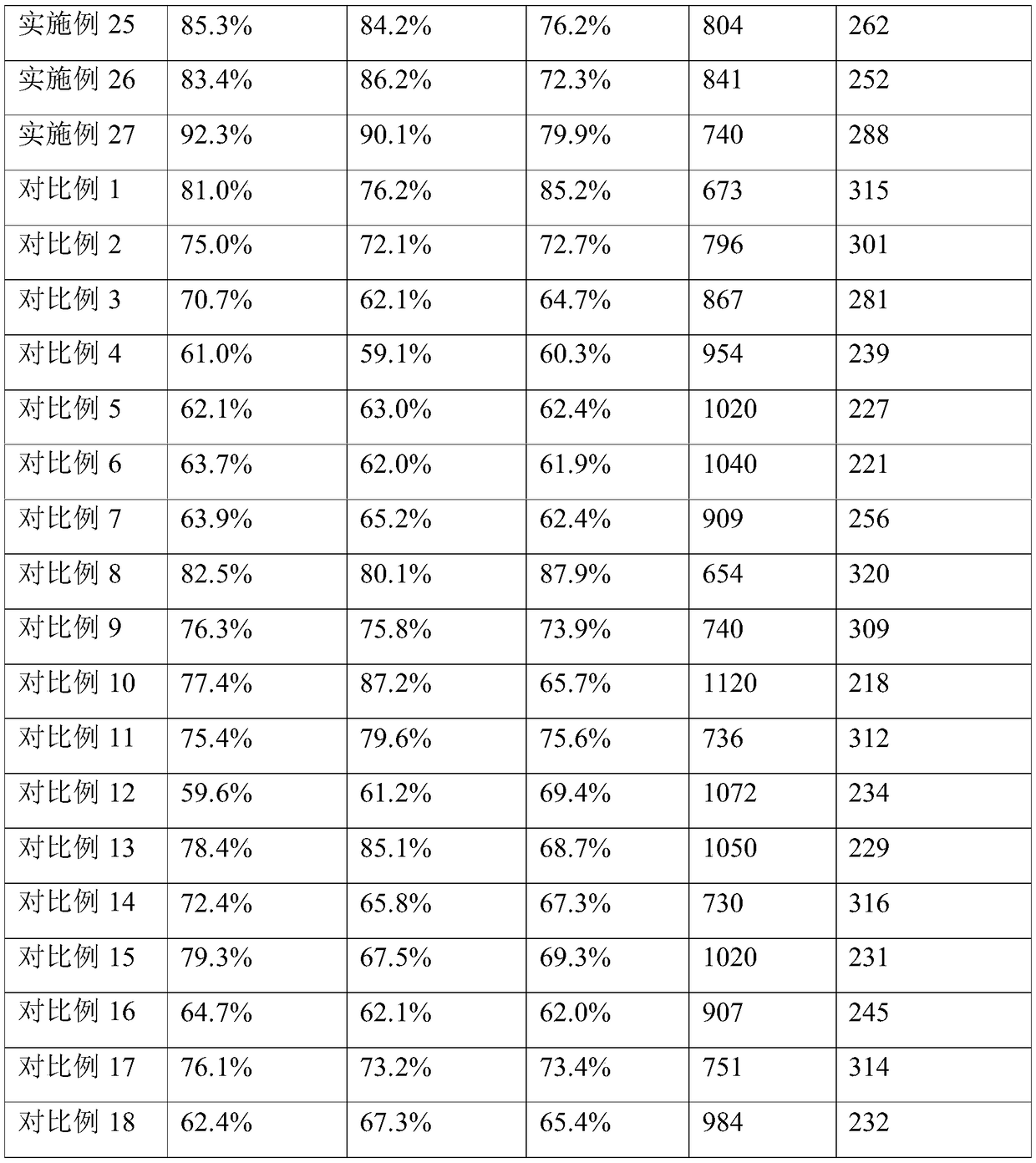

Examples

preparation example Construction

[0045] The present invention also provides a preparation method for the above-mentioned lithium-ion battery cathode material, which specifically includes the following steps:

[0046] Step 1, preparing the host material lithium-containing transition metal oxide Li x m y N 1-y o 2-α A β ;

[0047] The specific process of step 1 is as follows:

[0048] Choose a one-step method or a two-step method to prepare the host material. The one-step method refers to the raw material containing the desired transition metal element M, the Li source, the raw material containing the desired doping element N, and the raw material containing the desired doping element A, Lithium-containing transition metal oxides Li x m y N 1- y o 2-α A β , the preparation process is carried out in the air or oxygen environment; the two-step method refers to that the raw material containing the desired transition metal element M is first passed through solid-phase ball milling method, liquid-phase co...

Embodiment 1

[0060] The host material of the positive electrode material prepared in this embodiment is LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 , the coating modification is MgO·SiO 2 . The thickness of the cladding layer is 15 nm, and the mass fraction of the cladding modifier in the positive electrode material is 0.2%. The specific preparation method is:

[0061] First, the host material precursor was prepared by co-precipitation method: the NiSO 4 、CoSO 4 , MnSO 4 Dissolve in deionized water according to the metal atomic ratio 1:1:1, and prepare a mixed solution with a total concentration of metal ions of 1mol / L; then add the prepared 1mol / L NaOH solution while stirring, and control the temperature during this process At 75°C, after full reaction, the evacuated secondary spherical granular coprecipitate will be obtained, and its average particle size is controlled at 18-20um (the average particle size of the primary particle is 1.0-1.2um); the resulting coprecipitate After being washed thre...

Embodiment 2

[0064] The host material of the positive electrode material prepared in this embodiment is LiNi 0.5 co 0.2 mn 0.3 o 2 , the coating modification material is CaO·SiO 2 . The thickness of the cladding layer is 10 nm, and the mass fraction of the cladding modifier in the positive electrode material is 0.3%. Concrete preparation steps are:

[0065] First, the host material precursor was prepared by co-precipitation method: the NiSO 4 、CoSO 4 , MnSO 4 Dissolve in deionized water according to the metal atomic ratio of 5:3:2, and prepare a mixed solution with a total concentration of metal ions of 1mol / L; then add the prepared 1mol / L NaOH solution while stirring, and control the temperature during this process At 75°C, after full reaction, the evacuated secondary spherical granular coprecipitate will be obtained, and its average particle size is controlled at 10-12um (the average particle size of the primary particle is 1.5-2.0um); the resulting coprecipitate After washing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com