Method for preparing alkali lead chloride micro-nano structure crystal

A micro-nano structure, lead chloride technology, applied in structural parts, electrochemical generators, electrical components and other directions, can solve the problems of expensive raw materials, inability to meet large-scale, low cost, no complicated steps, etc., and achieve low cost. , uniform size, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A preparation method of basic lead chloride micro-nano structure crystal, the steps are as follows:

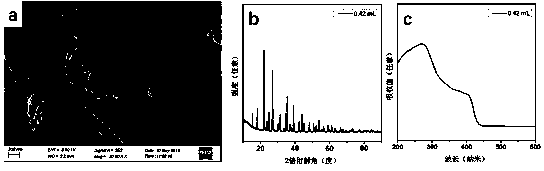

[0018] Synthesis of basic lead chloride (Pb(OH)Cl) micro-nano crystals. Take 3 mmol (0.8343 g) of lead chloride (PbCl 2 ), put it into a 100 mL three-necked bottle after grinding, add 80 mL deionized water, stir and heat to 60 o C, forming a clear and transparent solution. 3 mmol (0.42 mL) of triethylamine was added, and white flocs appeared in the solution. After reacting for 10 minutes, the heating was stopped, and the solution was cooled to room temperature. After suction filtration and drying, a solid powder was obtained. (Scanning electron microscope picture, X-ray diffraction picture and absorption spectrum are respectively as figure 1 a, 1b and 1c).

[0019] From the XRD diffraction results of the product, its peak positions are located at 2θ=15.370°, 18.201°, 22.150°, 23.901°, 24.992°, 26.667°, 27.080°, 30.304°, 31.148°, 31.474°, 33.626°, 34.910°, 35.567 ...

Embodiment 2

[0022] A preparation method of basic lead chloride micro-nano structure crystal, the steps are as follows:

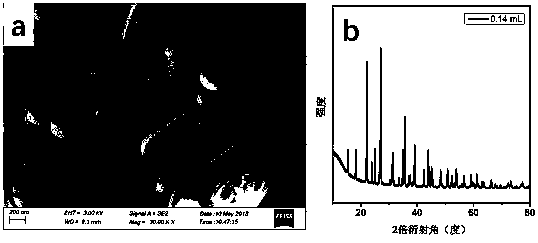

[0023] Synthesis of basic lead chloride (Pb(OH)Cl) micro-nano crystals. Take 3 mmol (0.8343 g) of lead chloride (PbCl 2 ), put it into a 100 mL three-necked bottle after grinding, add 80 mL deionized water, stir and heat to 60 o C, forming a clear and transparent solution. 1 mmol (0.14 mL) of triethylamine was added, and white flocs appeared in the solution. After reacting for 10 minutes, the heating was stopped, and the solution was cooled to room temperature. After suction filtration and drying, a solid powder was obtained. (Scanning electron microscopy and X-ray diffraction patterns are shown in figure 2 a and 2b).

Embodiment 3

[0025] A preparation method of basic lead chloride micro-nano structure crystal, the steps are as follows:

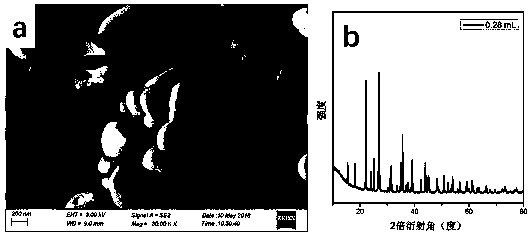

[0026] Synthesis of basic lead chloride (Pb(OH)Cl) micro-nano crystals. Take 3 mmol (0.8343 g) of lead chloride (PbCl 2 ), put it into a 100 mL three-necked bottle after grinding, add 80 mL deionized water, stir and heat to 60 o C, forming a clear and transparent solution. 2 mmol (0.28 mL) of triethylamine was added, and white flocs appeared in the solution. After reacting for 10 minutes, the heating was stopped, and the solution was cooled to room temperature. After suction filtration and drying, a solid powder was obtained. (Scanning electron microscopy and X-ray diffraction patterns are shown in image 3 a and 3b).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com