The preparation method of antibacterial type sma emulsion

A technology of emulsion and solution, which is applied in the field of polymer materials and nanomaterials, can solve the problems of producing bacteria, achieve the effect of improving antibacterial property and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] (1) Weigh 0.5g of macromolecule SMA (Mn=100000), dissolve it in 10ml of organic solvent DMF, stir vigorously, and slowly add ultrapure water dropwise at the same time, when blue opalescence appears, slowly add this solution dropwise In 100ml ultrapure water, and vigorously stirred to obtain SMA nano colloidal particles. (2) Take 10ml of the above-mentioned SMA nano colloidal particle solution, add dropwise 0.2mol / L AgNO3 solution 15μL, wrap it in tin foil to avoid light, and stir for 3 hours under the action of magnetic stirring to fully mix the colloidal particle and silver nitrate, then place Expose under ultraviolet light for 5 minutes to prepare a silver-loaded nano colloidal particle (nano SMA-Ag) solution. (3) Take 3 mL of the silver-loaded nano-colloid particle solution obtained in step (2), add 3 mL of white oil, emulsify with a high-speed disperser at a speed of 5000 r / min, and homogenize for 2 minutes to obtain an antibacterial emulsion.

Embodiment 2

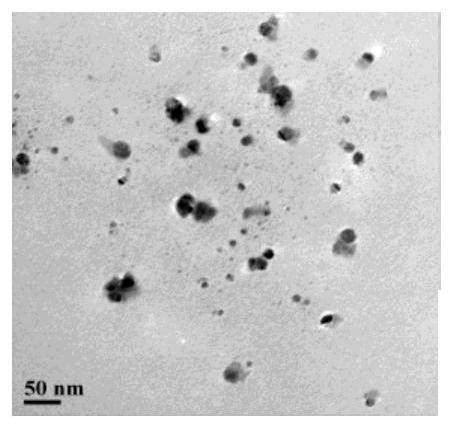

[0016] After diluting the silver-loaded nanocolloid particle (nano SMA-Ag) solution prepared in step 2 in Example 1, remove dust with a 0.45 μm filter, drop one drop onto the copper grid, dry at room temperature for 1 day, and observe the morphology with TEM , the result is as figure 1 shown. The results show that the particle size of nano-Ag is about 8-16nm (due to the contrast problem between Ag and SMA colloidal particles, the SMA colloidal particles in TEM are not clear), and it can be seen from the TEM image that nano-Ag can be well dispersed in SMA colloidal particles On or around the surface, this is because the SMA polymer contains a large number of carbonyl groups that can complex with nano-Ag.

Embodiment 3

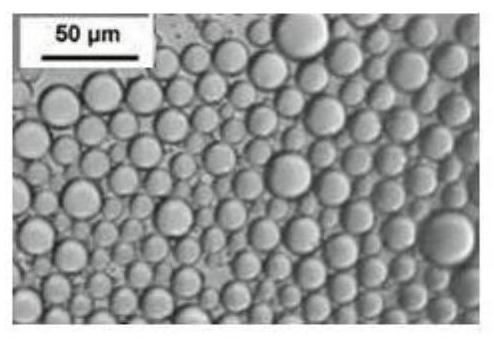

[0018] The silver-loaded nano colloid particle solution in embodiment 1 adds white oil emulsification and the photo is as follows figure 2 shown. It can be seen that it has good emulsifying performance and the emulsion properties are relatively stable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com