A kind of high-performance pet/pbt material for junction box of air conditioner compressor and preparation method thereof

A technology for air-conditioning compressor and junction box, applied in the field of polymer materials, can solve the problems of product rejection rate, poor impact resistance, low flame retardancy, etc. , the effect of improving stiffness and temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

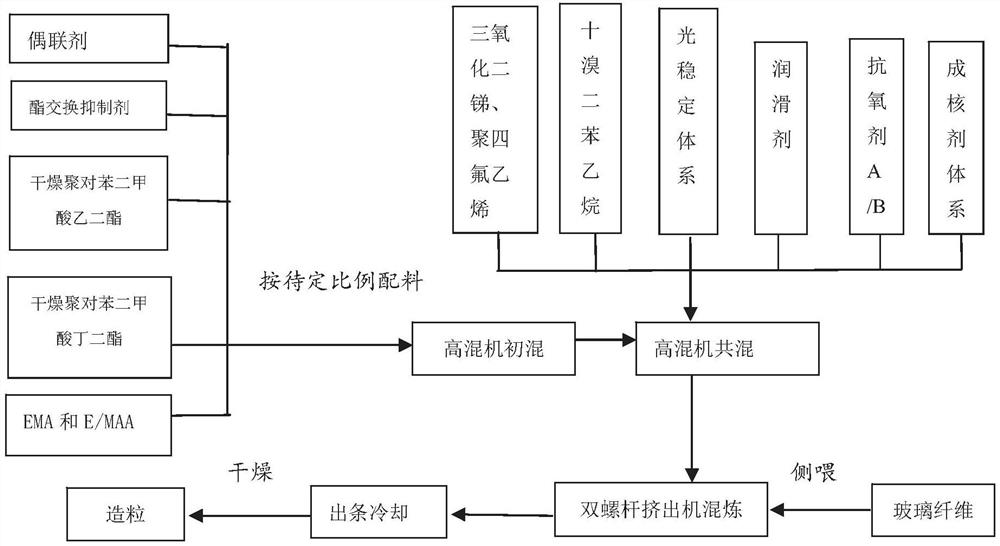

[0040] A preparation method of PET / PBT material, comprising the steps:

[0041] (1) Dry pretreatment of PET and PBT;

[0042] (2) The dried PET, PBT, EMA, E / MAA, and coupling agent are placed in a high-mixer and uniformly mixed to prepare mixture A; Decabromodiphenylethane and antimony trioxide are mixed again, and after mixing, the Nucleating agent, talc, nucleation accelerator, transesterification inhibitor, lubricant, antioxidant A, auxiliary antioxidant B, light stabilizer, polytetrafluoroethylene, and ultraviolet absorber are uniformly mixed together to prepare mixture B;

[0043] (3) Put the mixed mixture B into the mixed mixture A for uniform mixing again, and then add it to the twin-screw extruder after mixing evenly; the glass fiber is added to the twin-screw extruder by side feeding, Pelletized PET / PBT material.

[0044] The condition of drying pretreatment in step (1) is drying at 145-155° C. for 4-6 hours.

[0045] The temperature of each temperature zone of the...

Embodiment 1

[0050] A high-performance PET / PBT material for an air-conditioning compressor junction box, comprising in parts by weight: 46 parts of PET, 5 parts of PBT, 30 parts of glass fiber, 5 parts of EMA, 8 parts of decabromodiphenyl ethane, and 2 trioxide 5 parts of antimony, 0.1 part of PTFE, 5 parts of E / MAA, 0.1 part of HK-185P nucleating agent, 0.5 part of talc, 0.5 part of nucleation accelerator, 0.5 part of transesterification inhibitor, 0.2 part of light stabilizer, UV light 0.2 part of absorbent, 0.2 part of lubricant, 0.2 part of main antioxidant A, 0.2 part of auxiliary antioxidant B, and 0.2 part of coupling agent.

[0051] The coupling agent in this embodiment adopts silane coupling agent KH560.

[0052] A preparation method of PET / PBT material, comprising the steps:

[0053] (1) Dry and pretreat PET and PBT at 150°C for 4 hours; PET and PBT materials have a certain degree of hydrophilicity because of ester bonds in their molecular structures. The materials are more sens...

Embodiment 2 5

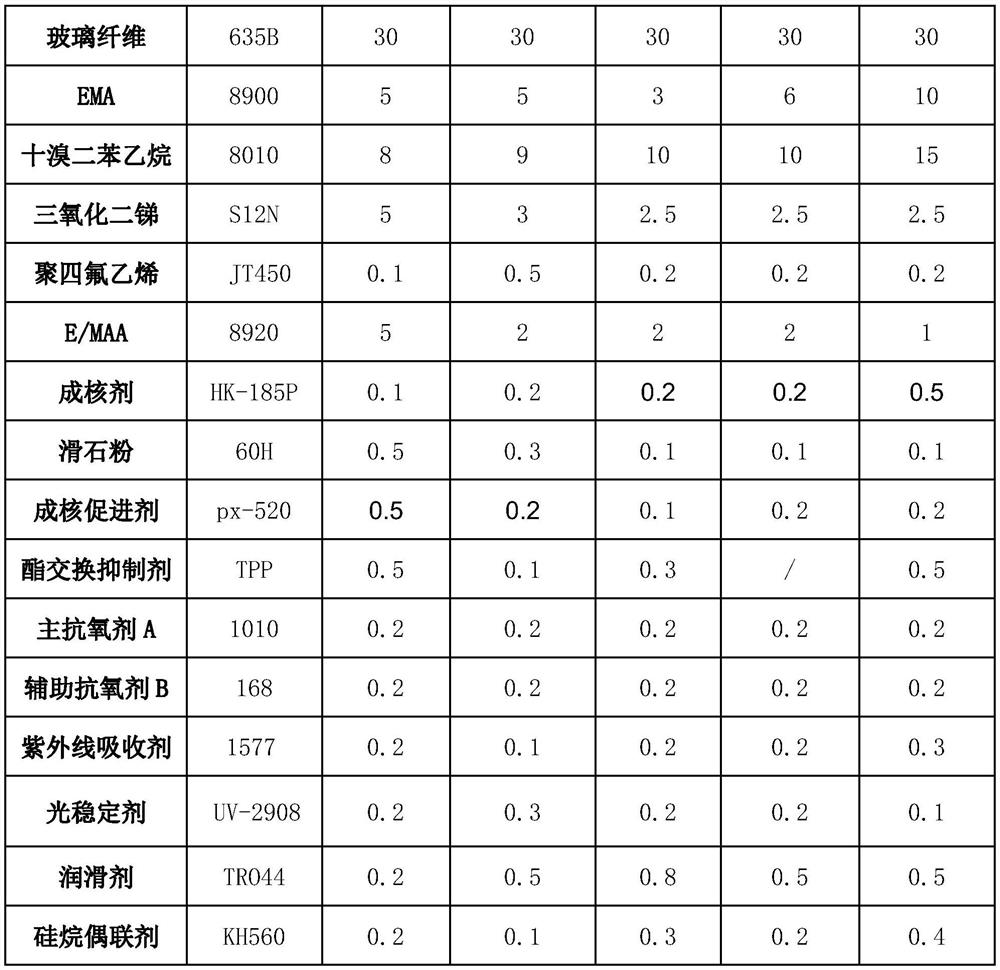

[0058] Prepared by adjusting the ratio of each raw material in the formula, the preparation method is the same as that in Example 1, and the distribution ratios of each group in Examples 2 to 5 are as follows:

[0059] Table 1

[0060]

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com