Waterborne polyurethane coating

A water-based polyurethane and coating technology, applied in the field of polymer materials and nanomaterials, can solve problems such as unsatisfactory dispersion and affect sterilization performance, and achieve the effect of ensuring compatibility and mild preparation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The preparation of embodiment 1 silver nano colloid particle solution

[0015] (1) Weigh 0.5g of macromolecule SMA (Mn=100000), dissolve it in 10ml of organic solvent DMF, stir vigorously, and slowly add ultrapure water dropwise at the same time, when blue opalescence appears, slowly add this solution dropwise In 100ml ultrapure water, and vigorously stirred to obtain SMA nano colloidal particles. (2) Take 10ml of the above-mentioned SMA nano colloidal particle solution, add dropwise 0.2mol / L AgNO3 solution 15μL, wrap it in tin foil to avoid light, and stir for 3 hours under the action of magnetic stirring to fully mix the colloidal particle and silver nitrate, then place Expose under ultraviolet light for 5 minutes to prepare a silver nano colloid particle (nano SMA-Ag) solution.

Embodiment 2

[0016] The characterization of embodiment 2 silver nano colloid particle solution

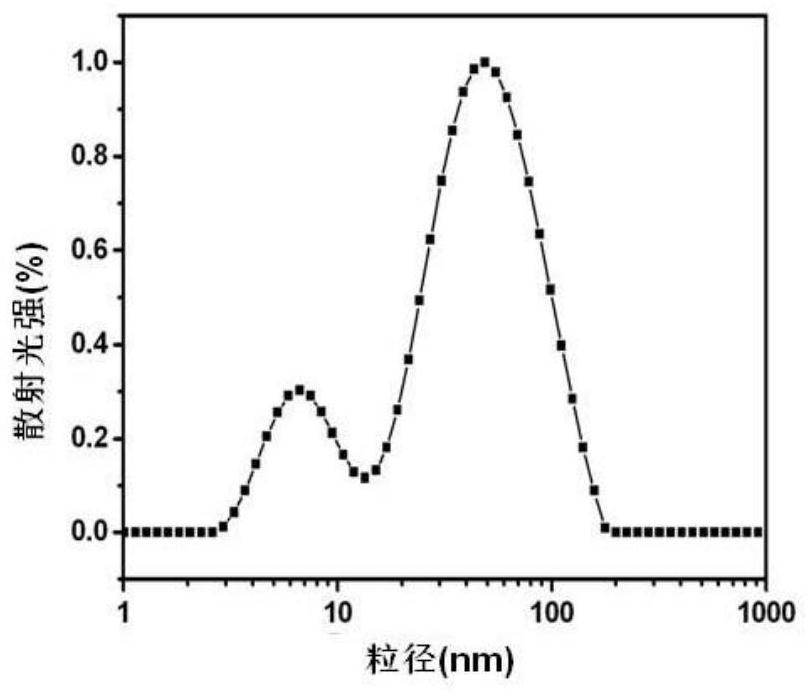

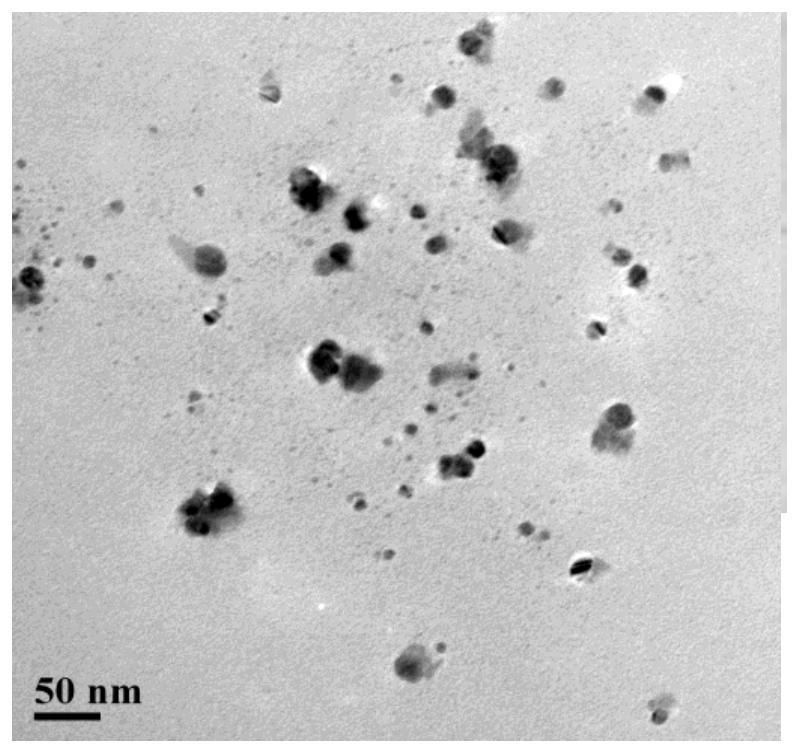

[0017] After the silver-loaded nano colloid particle (nanoSMA-Ag) solution that step 2 in the embodiment 1 makes is diluted, after dedusting with a 0.45 μm filter membrane, test its particle size distribution with dynamic laser light scattering (DLS), the result Such as figure 1 . And the above-mentioned solution after dedusting by filter membrane was dropped drop by drop on the copper grid, and after drying at room temperature for 1 day, the morphology was observed with TEM, and the results were as follows: figure 2 shown. DLS results show that there are two peaks on the particle size distribution diagram, the nano-silver at 8-12nm, and the peak at about 70nm comes from SMA nanoparticles. The TEM results show that the nano-Ag particle size is about 8-16nm (due to the contrast problem between Ag and SMA colloidal particles, the SMA colloidal particles in TEM are not clear), and it can be se...

Embodiment 3

[0018] The preparation of embodiment 3 waterborne polyurethane coatings

[0019] Add the silver nano-colloid particle solution that embodiment 1 makes in water-based polyurethane resin, and add auxiliary agent, concrete composition is: 100 parts of water-based polyurethane resin, 5 parts of silver nano-colloid particles, 2 parts of water-based defoamer, leveling agent 2 servings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com