Preparation method of organophosphorus compound modified ZSM-5 zeolite

A ZSM-5 and compound technology, applied in the field of ZSM-5 zeolite, can solve the problems of poor zeolite pores and poor hydrothermal stability of ZSM-5 zeolite, and achieve the effect of protecting zeolite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

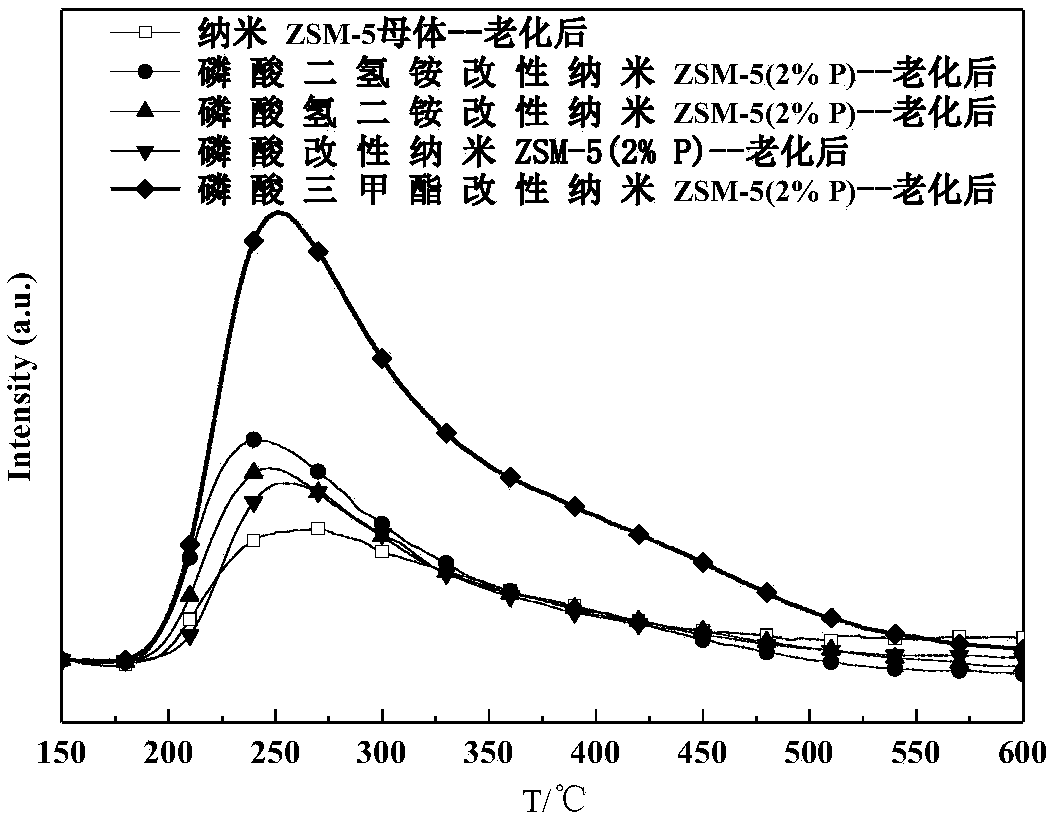

[0045] (1) Referring to patent CN102502696B to synthesize nano ZSM-5 zeolite raw powder, and obtain nano H-type ZSM-5 zeolite through ammonium exchange and acid pore expansion. Before modification, the nano ZSM-5 zeolite is calcined to remove water. The calcination temperature is 540°C; the calcination time is 6 hours.

[0046] (2) Perform phosphorus impregnation modification on the calcined nanometer ZSM-5 zeolite obtained in (1). Specific process: at room temperature, stir and impregnate 30 g of calcined nano H-type ZSM-5 zeolite in a cyclohexane solution of trimethyl phosphate prepared in advance for 12 hours. The amount of trimethyl phosphate is 1.36g, and it is configured as a 150ml solution with cyclohexane, and the concentration of trimethyl phosphate is 0.065mol / L. The volume ratio of the calcined nano H-type ZSM-5 zeolite to the cyclohexane solution of trimethyl phosphate is 6:1.

[0047] (3) The solvent used for impregnation is removed by distillation. The distilla...

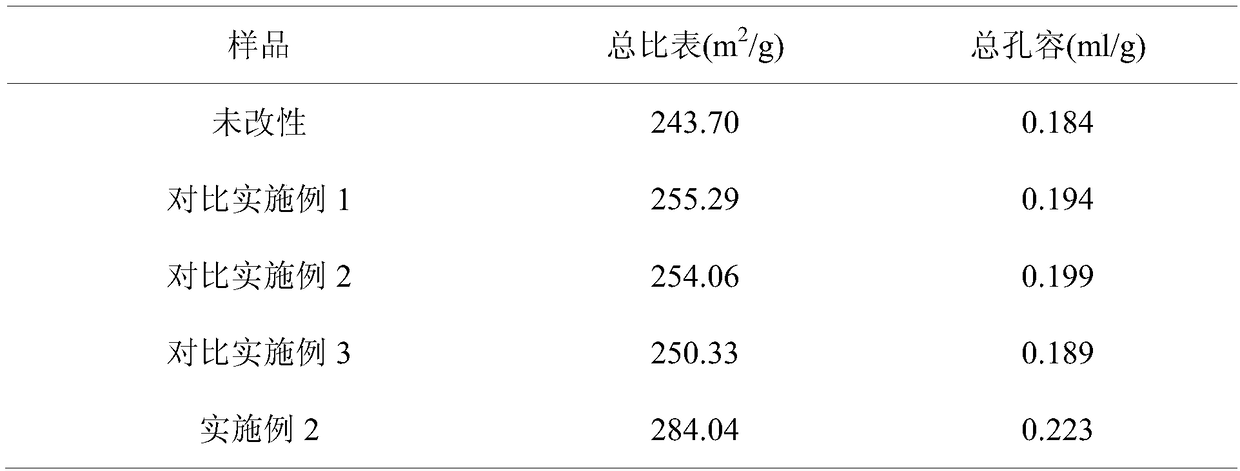

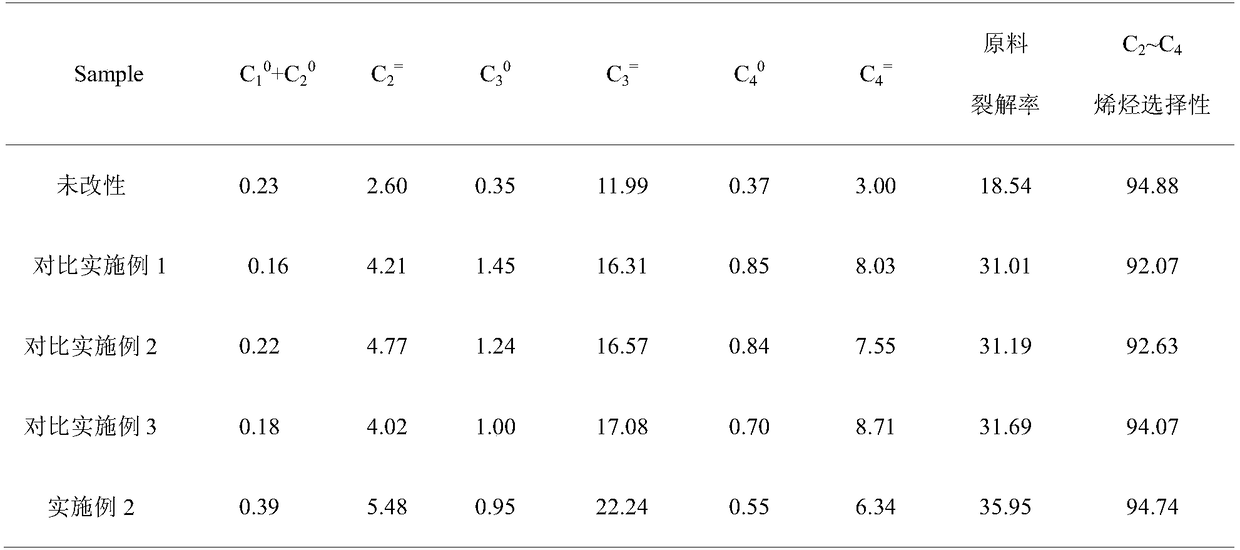

Embodiment 2

[0052] Repeat Example 1, but change the amount of trimethyl phosphate to 2.72g and add cyclohexane to configure 150ml solution, the concentration of trimethyl phosphate is 0.13mol / L, and the mass percentage of P obtained is 2% trimethyl phosphate Ester-modified ZSM-5 zeolite.

Embodiment 3

[0054] Repeat Example 1, but change the amount of trimethyl phosphate to 4.08g, add cyclohexane to configure a 150ml solution, the concentration of trimethyl phosphate is 0.195mol / L, and the mass percentage of P obtained is 3% triphosphate Methyl ester modified ZSM-5 zeolite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com