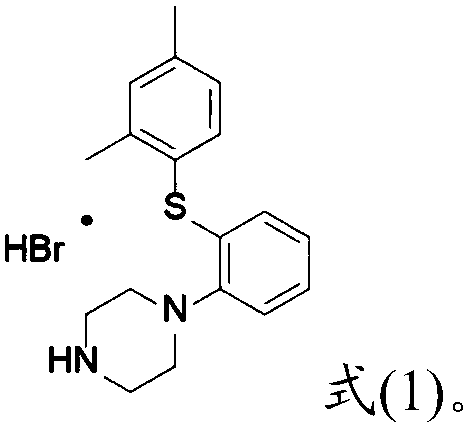

Clean production method of antidepressant drug intermediate

An ammonium paratungstate, supported technology, used in the field of medicine, can solve the problems of large environmental pollution and easy deactivation of catalysts, and achieve the effects of overcoming poisoning and deactivation, improving the reaction rate and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

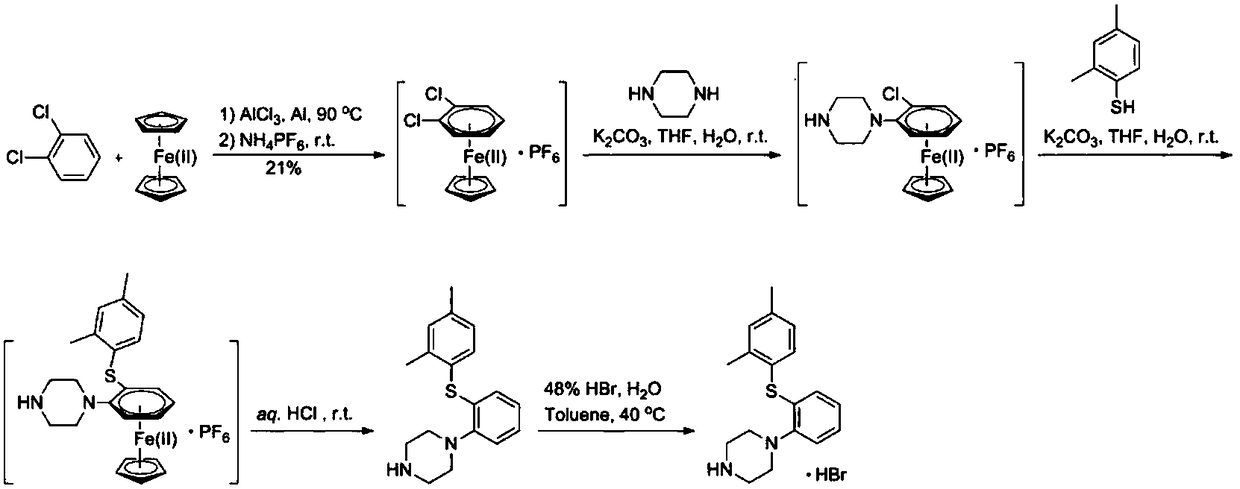

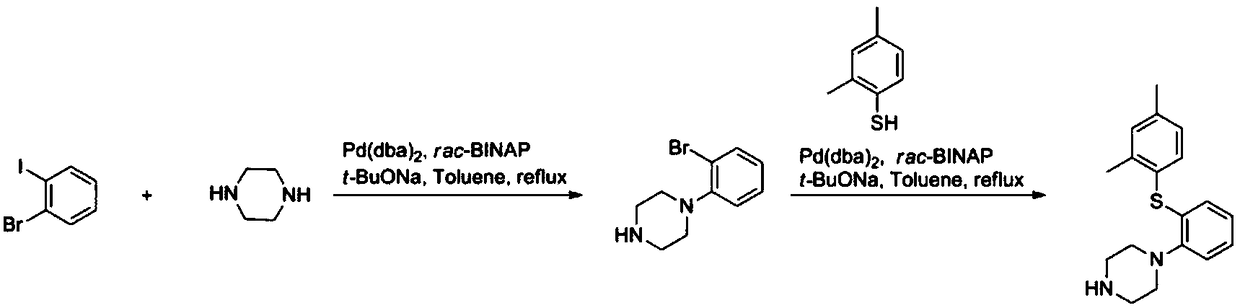

Method used

Image

Examples

Embodiment 1

[0045] Prepare the loaded Pd catalyst modified by ammonium paratungstate as follows:

[0046] 1) Add 0.3g of ammonium paratungstate to 100ml of purified water, raise the temperature to 60-80°C, then add 10.0g of alumina-doped silica and stir for 6-8h to obtain the first dispersion;

[0047] 2) Add 62ml of 0.1mol / L K dropwise to the first dispersion 2 PdCl 4 Aqueous solution (the loading capacity of Pd on alumina-doped silica is about 6.6%wt), after the dropwise addition, keep stirring at 60-80°C to obtain the second dispersion;

[0048] 3) Lower the temperature of the second dispersion to 10-20°C, and then dropwise add 260ml of 0.3mol / L sodium borohydride aqueous solution to carry out the reduction reaction. After the dropwise addition, the temperature is gradually raised to 50-60°C and kept for 2-3 hours to obtain the third Dispersions;

[0049] 4) Cool the third dispersion to room temperature, filter, wash with water, and collect the filter cake until there is no chloride...

Embodiment 1-A

[0051] Compared with Example 1, 0.3 g of ammonium paratungstate is not added in step 1), and the rest is completely consistent with Example 1, and the prepared catalyst is defined as Pd@Al-Si.

Embodiment 1-B

[0053] Compared with Example 1, 10.0 g of activated carbon was used instead of alumina-doped silica, and the rest were completely consistent with Example 1, and the prepared catalyst was defined as Pd@C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com