Method for preparing nearly-zero VOC (volatile organic compound) alkyd resin from gutter oil and alkyd resin

A technology of alkyd resin and waste oil, applied in the field of coatings, can solve problems such as inability to do it, achieve excellent environmental protection, reduce production costs, and achieve the effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

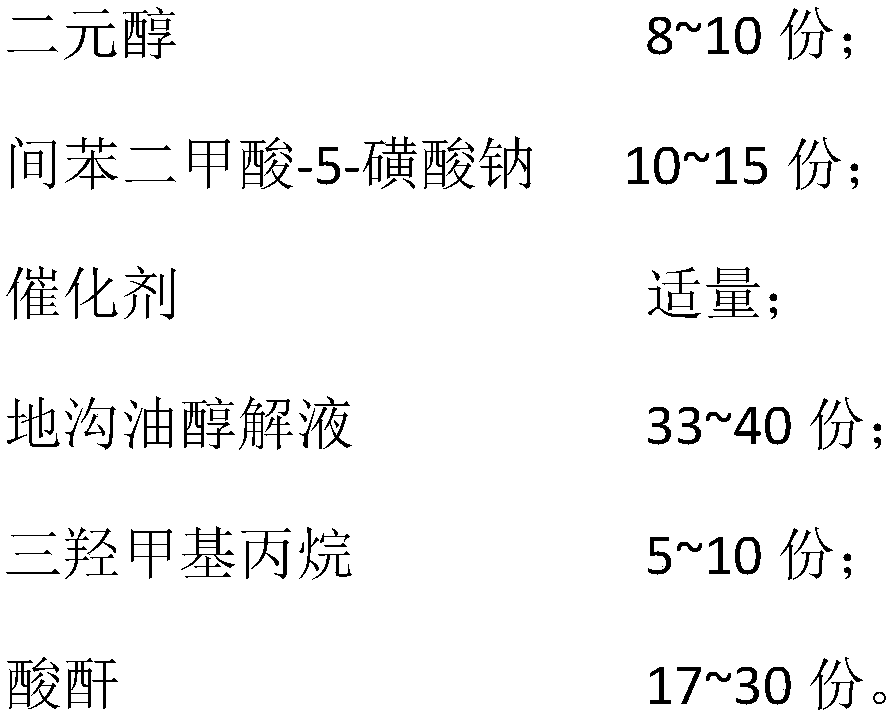

Method used

Image

Examples

Embodiment 1

[0044] Preparation of waste oil alcoholysis solution: Put 85 parts by mass of refined waste oil and 15 parts by mass of pentaerythritol into the reaction kettle, heat up to 180°C, then add 0.03 parts by mass of lithium hydroxide, continue to heat up to 270°C, and react for 2 hours When the mixture obtained by mixing the reaction product and ethanol at a mass ratio of 1:1 is clear and transparent, the reaction can be ended and the temperature can be lowered for later use.

[0045] Among them, refined waste oil was purchased from Zhejiang Qingcaodi Holdings Co., Ltd.

Embodiment 2

[0047] An environment-friendly alkyd resin prepared from waste oil, prepared through the following steps:

[0048] Mix 8 parts by mass of neopentyl glycol, 10 parts by mass of sodium isophthalate-5-sulfonate and 0.02 parts by mass of stannous octoate; slowly heat up to 200°C within 5 hours; add 33 Parts by mass of waste oil alcoholysis solution, 5 parts by mass of trimethylolpropane, 15 parts by mass of phthalic anhydride, and 2 parts by mass of maleic anhydride, heat up to 220°C and keep warm for about 1 hour. When the viscosity of the product reaches the predetermined When the value is high, cool down and filter and pack.

[0049] It is worth mentioning that the predetermined value of the viscosity is: when the product and butyl glycol ether are mixed at a mass ratio of 1:1, the viscosity of the grate tube is greater than 1 second.

Embodiment 3

[0051] An environment-friendly alkyd resin prepared from waste oil, prepared through the following steps:

[0052] Mix 10 parts by mass of neopentyl glycol, 15 parts by mass of sodium isophthalic acid-5-sulfonate and 0.02 parts by mass of stannous octoate; slowly heat up to 200°C within 5 hours; add 40 Parts by mass of waste oil alcoholysis solution, 10 parts by mass of trimethylolpropane, 25 parts by mass of phthalic anhydride, and 5 parts by mass of maleic anhydride, heat up to 220°C and keep warm for about 1 hour. When the viscosity of the product reaches the predetermined When the value is high, cool down and filter and pack.

[0053] It is worth mentioning that the predetermined value of the viscosity is: when the product and butyl glycol ether are mixed at a mass ratio of 1:1, the viscosity of the grate tube is greater than 1 second.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com