Fouling-resistant energy-saving environment-friendly stone-like coating material and preparation method thereof

A stone-like coating, energy-saving and environment-friendly technology, applied in anti-fouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of no heat preservation and energy saving effect, monotonous decorative effect, poor pollution resistance, etc., to achieve Equipment requirements and process elements are not harsh, meet the requirements of industrial scale-up production, and have excellent thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

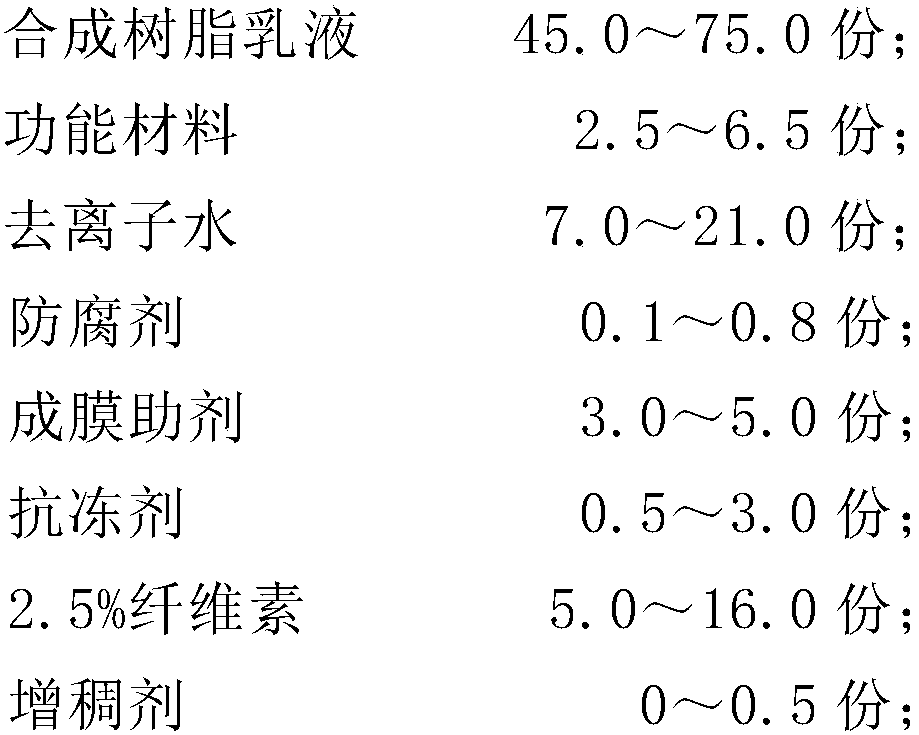

[0036] Step 1: Preparation of base material components:

[0037] Take by weight 60.0 parts of synthetic resin emulsion, 3.0 parts of functional materials, 20.8 parts of deionized water, 0.6 parts of preservatives, 4.0 parts of film-forming aids, 1.2 parts of antifreeze, 10.0 parts of 2.5% cellulose and thickener 0.4 copies;

[0038] First add the formula amount of emulsion into a container with a stirring device, start the stirring device, control the speed at 300-1000r / min, slowly add the weighed functional materials in 3 times, and stir evenly. Add the amount of water according to the degree of difficulty, then slowly add preservatives, film-forming aids, antifreeze and 2.5% cellulose in sequence, and stir evenly; finally, add a thickener to adjust the viscosity for later use.

[0039] Step 2: Paint:

[0040] After preparing the base material, adjust the rotation speed to 1000-1200r / min, slowly add the powder component in the formula amount according to the weight ratio of...

Embodiment 2

[0043] Step 1: Preparation of base material components:

[0044] Take by weight 70.0 parts of synthetic resin emulsion, 4.5 parts of functional materials, 12.2 parts of deionized water, 0.7 parts of preservatives, 3.5 parts of film-forming aids, 0.9 parts of antifreeze, 8.0 parts of 2.5% cellulose and thickener 0.2 copies;

[0045] First add the formula amount of emulsion into a container with a stirring device, start the stirring device, control the speed at 300-1000r / min, slowly add the weighed functional materials in 4 times, and stir evenly. Add the amount of water according to the degree of difficulty, then slowly add preservatives, film-forming aids, antifreeze and 2.5% cellulose in sequence, and stir evenly; finally, add a thickener to adjust the viscosity for later use.

[0046] Step 2: Paint:

[0047] After preparing the base material, adjust the rotation speed to 1000-1200r / min, slowly add the powder component in the formula amount according to the weight ratio of ...

Embodiment 3

[0050] Step 1: Preparation of base material components:

[0051] Take by weight 75.0 parts of synthetic resin emulsion, 6.0 parts of functional materials, 7.0 parts of deionized water, 0.8 parts of preservatives, 4.5 parts of film-forming aids, 0.6 parts of antifreeze, 6.0 parts of 2.5% cellulose and thickener 0.1 copies;

[0052] First add the formula amount of emulsion into a container with a stirring device, start the stirring device, control the speed at 300-1000r / min, slowly add the weighed functional materials in 5 times, and stir evenly. Add the amount of water according to the degree of difficulty, then slowly add preservatives, film-forming aids, antifreeze and 2.5% cellulose in sequence, and stir evenly; finally, add a thickener to adjust the viscosity for later use.

[0053] Step 2: Paint:

[0054] After preparing the base material, adjust the rotation speed to 1000-1200r / min, slowly add the powder component in the formula amount according to the weight ratio of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com