Fluorubber oil-resistant metal bottle cap sealant and preparation method thereof

A technology of fluorine rubber and oil resistance, which is applied in the field of fluorine rubber oil-resistant metal bottle cap sealant and its preparation. It can solve the problems of not meeting food hygiene requirements, migration of sealant components, and affecting food quality, so as to improve hydrophobicity. As well as the effects of flexibility, improved stability, and improved oil and stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

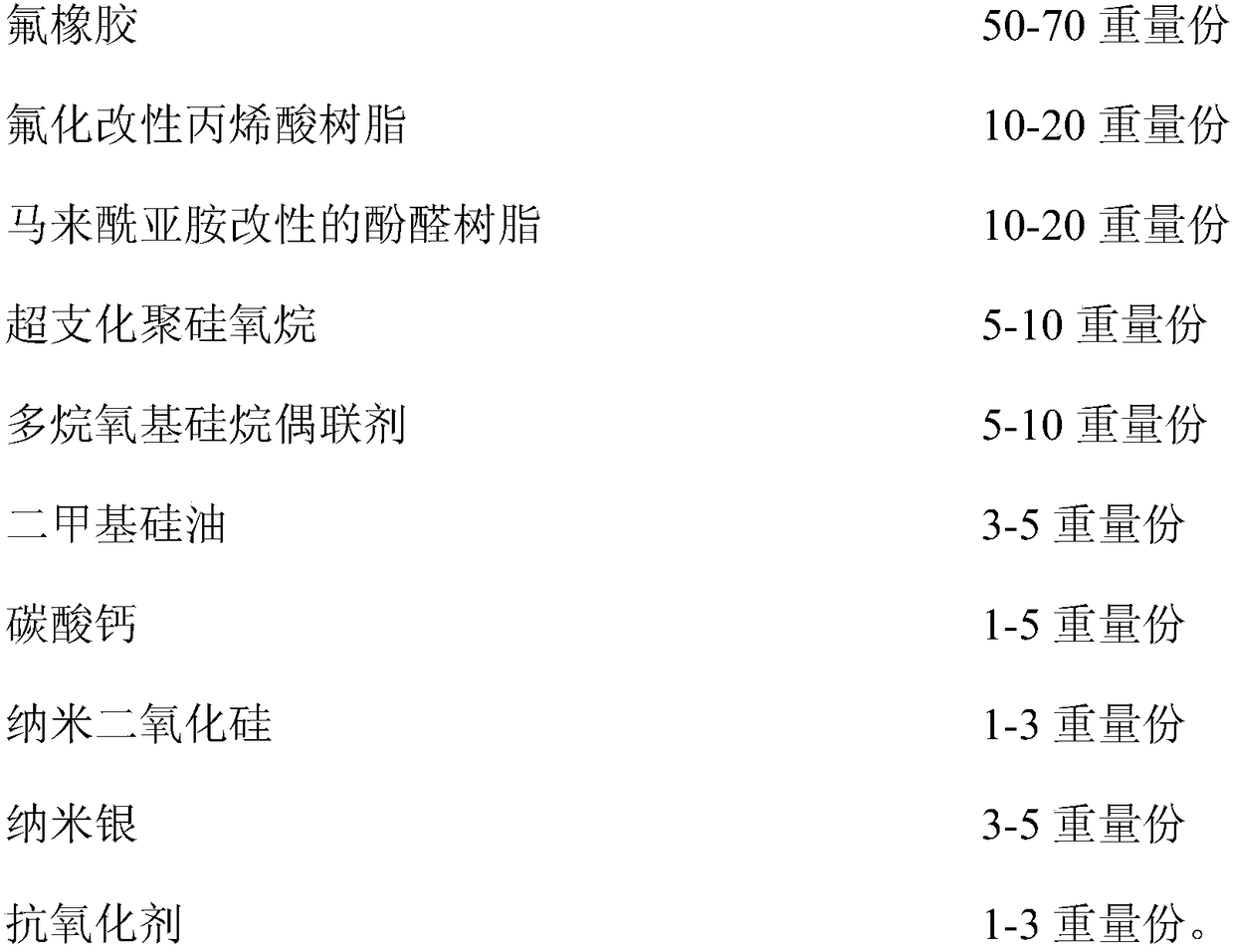

[0048] In this embodiment, the provided raw materials for preparing the fluororubber oil-resistant metal bottle cap sealant include the following components by weight:

[0049]

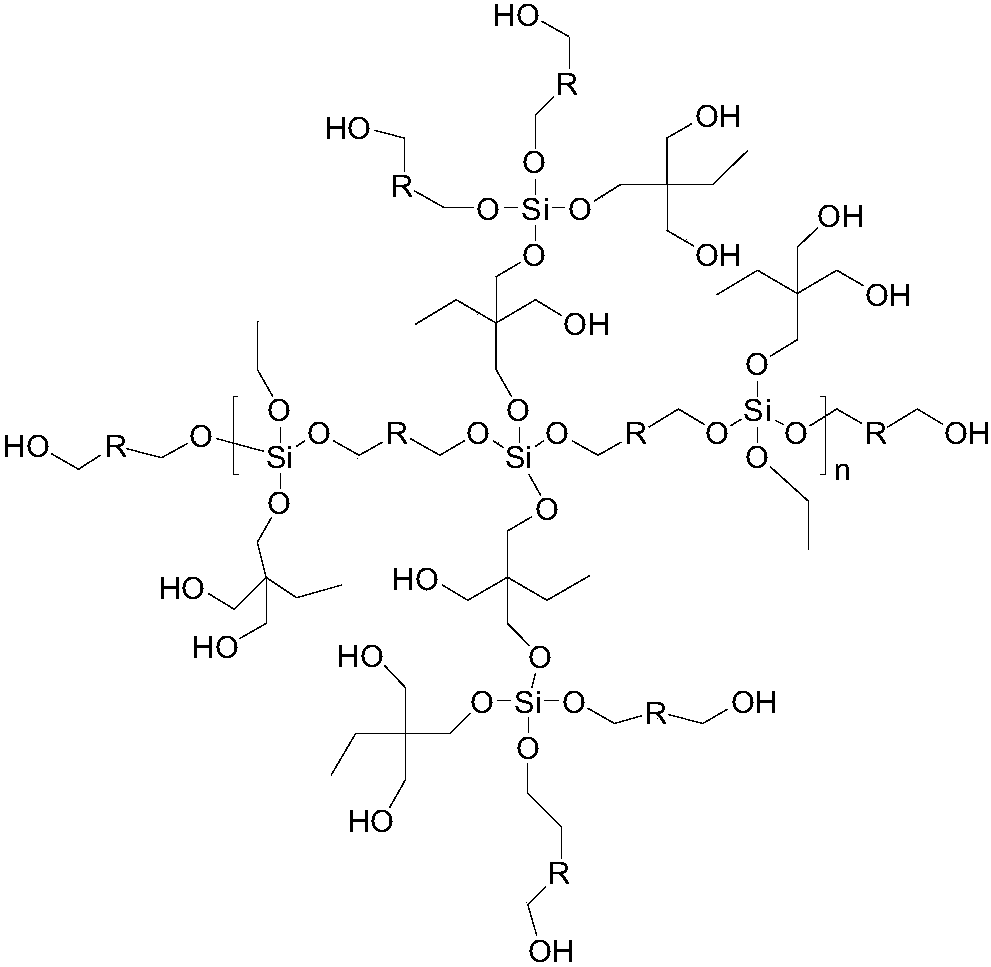

[0050] The structure of the hyperbranched polysiloxane is as follows:

[0051] Where R is -CH 2 CH 2 -, n is 4.

[0052] The polyalkoxysilane coupling agent is a hexaalkoxysilane coupling agent, and the antioxidant is antioxidant 1010.

[0053] The preparation method of the fluorine rubber oil-resistant metal bottle cap sealant specifically includes the following steps:

[0054] (1) Combine a part (30 parts by weight) of fluorine rubber with fluorinated modified acrylic resin, maleimide modified phenolic resin, dimethyl silicone oil, and part (3 parts by weight) of polyalkoxysilane coupling agent well mixed;

[0055] (2) Mix the remaining polyalkoxysilane coupling agent with calcium carbonate, nano-silica, nano-silver and antioxidants, and stir for 1 hour under vacuum conditions (vacuum degree of -0.4Mpa) to o...

Embodiment 2

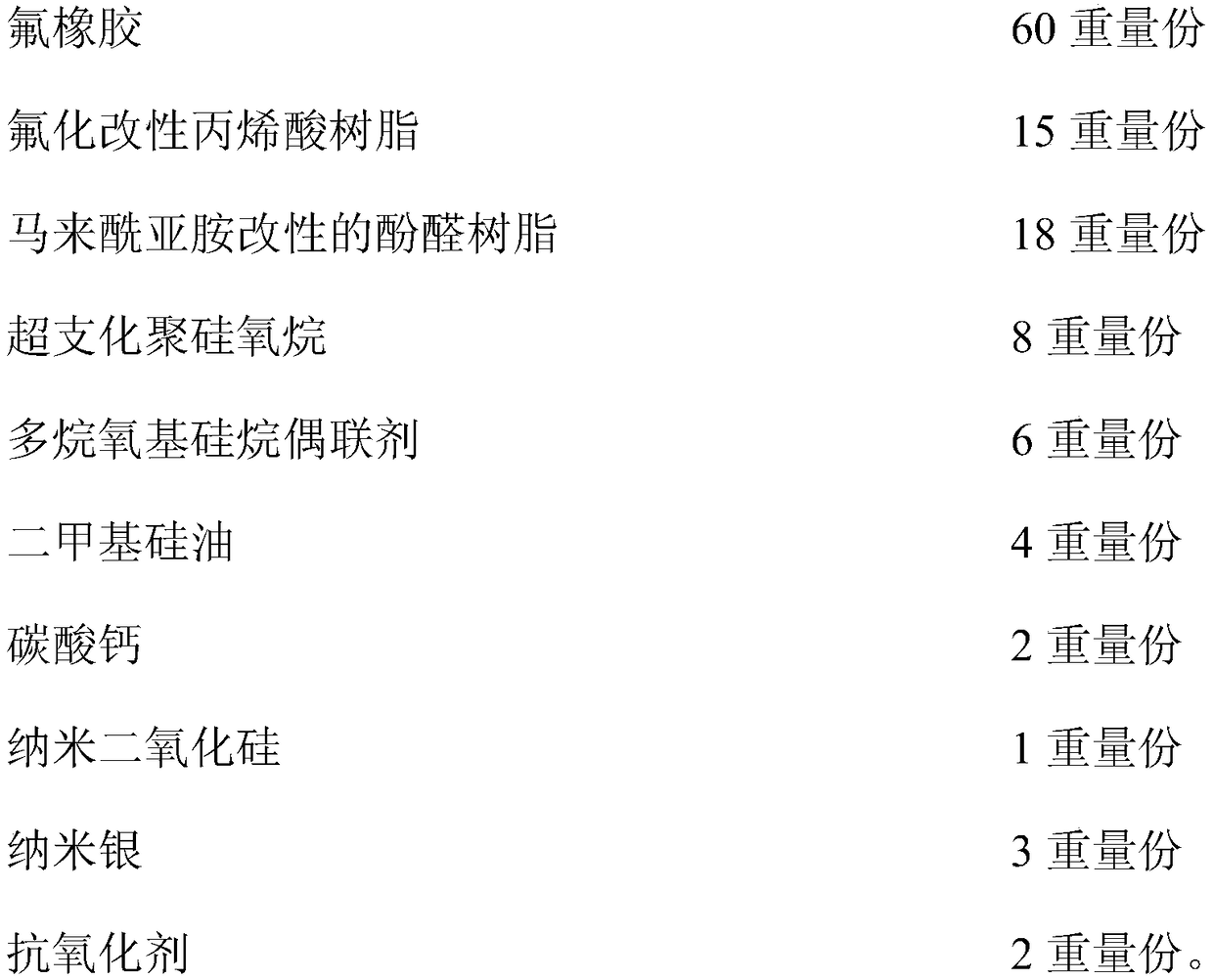

[0059] In this embodiment, the provided raw materials for preparing the fluororubber oil-resistant metal bottle cap sealant include the following components by weight:

[0060]

[0061] The structure of the hyperbranched polysiloxane is as follows:

[0062] Where R is -CH 2 CH 2 CH 2 -, n is 3.

[0063] The polyalkoxysilane coupling agent is a hexaalkoxysilane coupling agent, and the antioxidant is antioxidant 1010.

[0064] The preparation method of the fluorine rubber oil-resistant metal bottle cap sealant specifically includes the following steps:

[0065] (1) Combine a part (30 parts by weight) of fluorine rubber with fluorinated modified acrylic resin, maleimide modified phenolic resin, dimethyl silicone oil, and part (3 parts by weight) of polyalkoxysilane coupling agent well mixed;

[0066] (2) Mix the remaining polyalkoxysilane coupling agent with calcium carbonate, nano-silica, nano-silver and antioxidants, and stir for 2.5 hours under vacuum conditions (vacuum degree -0.6Mpa)...

Embodiment 3

[0070] In this embodiment, the provided raw materials for preparing the fluororubber oil-resistant metal bottle cap sealant include the following components by weight:

[0071]

[0072] The structure of the hyperbranched polysiloxane is as follows:

[0073] Where R is -CH 2 CH 2 -, n is 6.

[0074] The polyalkoxysilane coupling agent is a hexaalkoxysilane coupling agent, and the antioxidant is antioxidant 1010.

[0075] The preparation method of the fluorine rubber oil-resistant metal bottle cap sealant specifically includes the following steps:

[0076] (1) Combine a part (30 parts by weight) of fluorine rubber with fluorinated modified acrylic resin, maleimide modified phenolic resin, dimethyl silicone oil, and part (5 parts by weight) of polyalkoxysilane coupling agent well mixed;

[0077] (2) Mix the remaining polyalkoxysilane coupling agent with calcium carbonate, nano-silica, nano-silver and antioxidants, and stir for 3 hours under vacuum conditions (vacuum degree -0.5Mpa) to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com