Method for preparing nitrogen-doped nickel sulfide hydrogen evolution catalyst by using annealing method and application of method

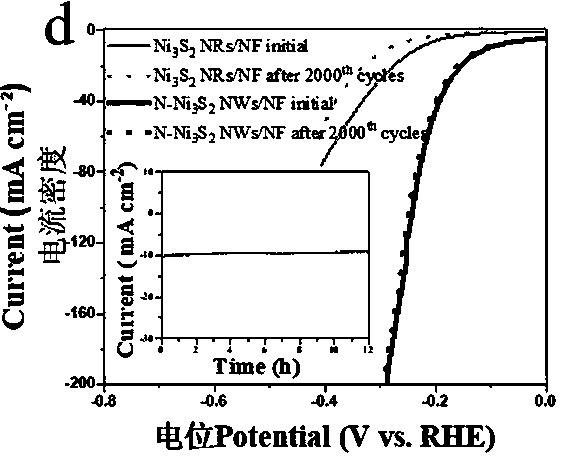

A technology of nitrogen doping and nickel sulfide, applied in the field of electrocatalytic hydrogen evolution, to achieve the effects of simple method, increased electrical conductivity, and enhanced hydrogen evolution reaction activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The method for preparing nitrogen-doped nickel sulfide hydrogen evolution catalyst by annealing method is to weigh 0.5 g thiourea and place it in a porcelain boat, and transfer it to the upstream of the temperature-programmed tube furnace, then take a piece of processed nickel foam and place it in another A ceramic boat, and transfer it to the downstream of the temperature-programmed tube furnace, under the protection of nitrogen, heat the temperature-programmed tube furnace to 400 °C at a heating rate of 5 °C / min, keep it for 90 min, and cool it down to room temperature naturally , taken out, that is, nitrogen-doped nickel sulfide (N-Ni 3 S 2 / NF).

Embodiment 2

[0044] The method for preparing nitrogen-doped nickel sulfide hydrogen evolution catalyst by annealing method is to weigh 1.0 g thiourea and place it in a porcelain boat, and transfer it to the upstream of the temperature-programmed tube furnace, and then take a piece of processed nickel foam and place it in another A ceramic boat, and transfer it to the downstream of the temperature-programmed tube furnace, under the protection of nitrogen, heat the temperature-programmed tube furnace to 400 °C at a heating rate of 5 °C / min, keep it for 90 min, and cool it down to room temperature naturally , taken out, that is, nitrogen-doped nickel sulfide (N-Ni 3 S 2 / NF).

Embodiment 3

[0046] The method for preparing nitrogen-doped nickel sulfide hydrogen evolution catalyst by annealing method takes 1.5 g thiourea and places it in a porcelain boat, and transfers it to the upstream of the temperature-programmed tube furnace, then takes a piece of processed nickel foam and places it in another A ceramic boat, and transfer it to the downstream of the temperature-programmed tube furnace, under the protection of nitrogen, heat the temperature-programmed tube furnace to 400 °C at a heating rate of 5 °C / min, keep it for 90 min, and cool it down to room temperature naturally , taken out, that is, nitrogen-doped nickel sulfide (N-Ni 3 S 2 / NF).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com