System and method for monitoring operation state of magnetic valve type controllable reactor and excitation unit of magnetic valve type controllable reactor

A condition monitoring system and unit operation technology, applied in signal transmission systems, instruments, measuring electricity and other directions, can solve the problems of weak current temperature signal interference, eddy current loss heating, data drift and other problems, to overcome the insulation level and long-distance transmission, guarantee Reliability and stability, achieve the level of maintenance and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

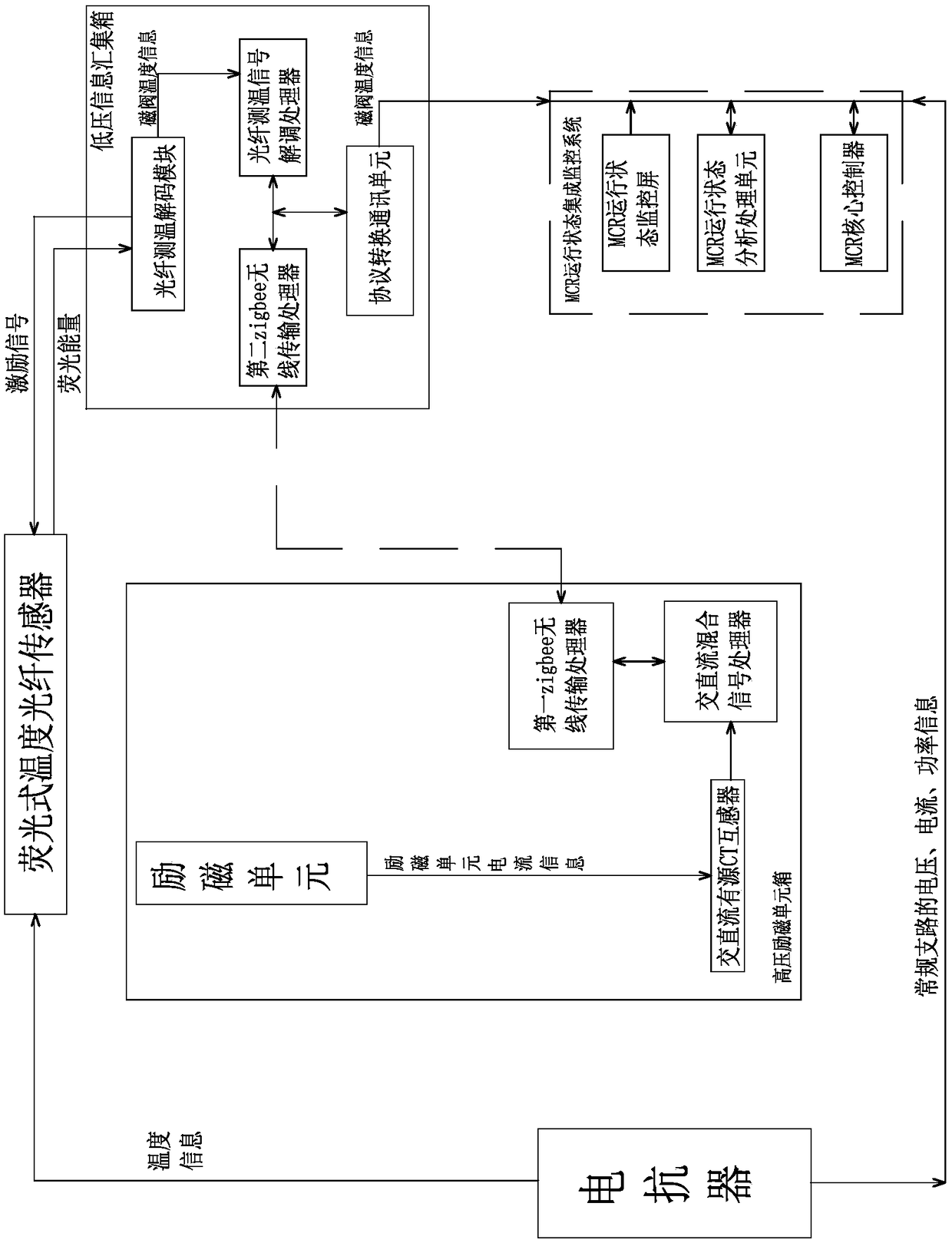

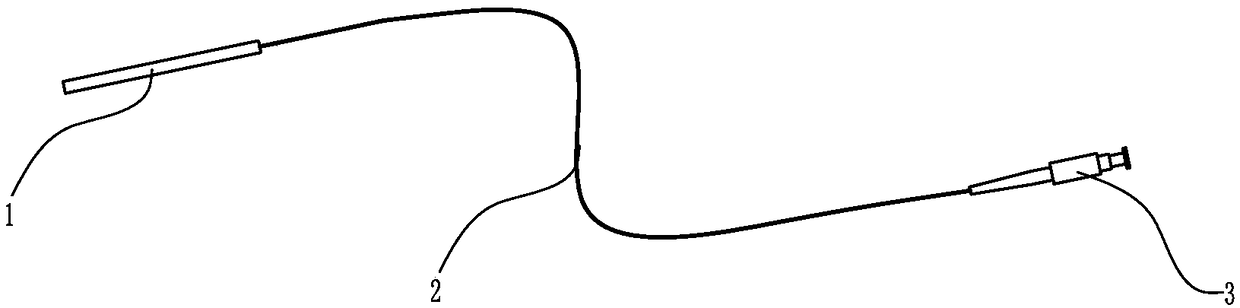

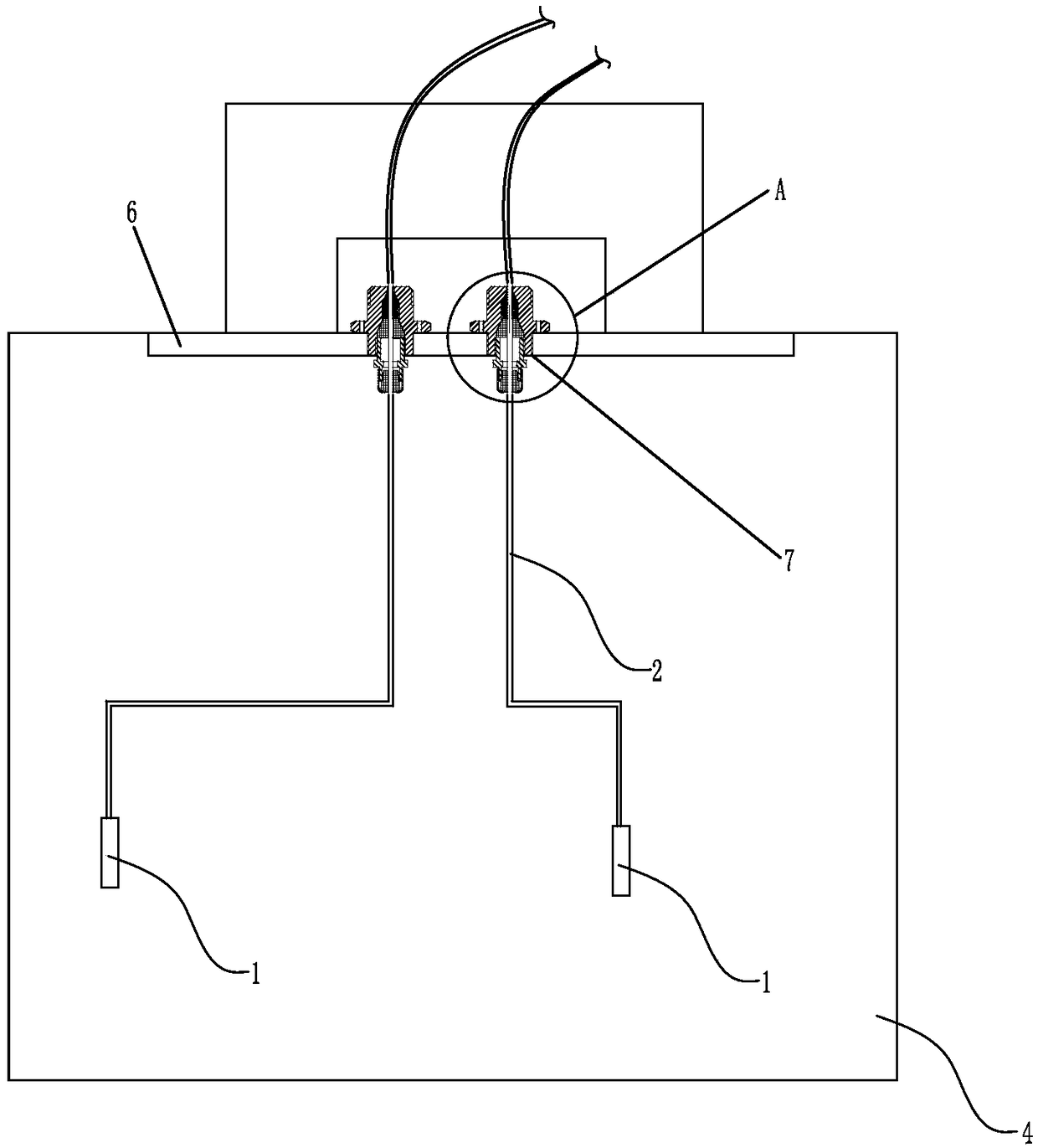

[0037] This embodiment provides a magnetic valve type controllable reactor and its excitation unit operating state monitoring system, such as Figure 1-2 As shown, it includes a fluorescent temperature optical fiber sensor, a high-voltage excitation unit box, a low-voltage information collection box, and an integrated monitoring system for MCR operation status. and a temperature measurement signal connector 3, one end of the temperature-resistant optical fiber 2 is connected to the temperature measurement probe 1, and the other end is connected to the temperature measurement signal connector 3, and the surface of the temperature-resistant optical fiber is wrapped with polytetrafluoroethylene. The high-voltage excitation unit box is provided with an excitation unit, an AC-DC active CT transformer, an AC-DC mixed signal processor and a first Zigbee wireless transmission processor; The buffer is composed of and connected to the reactor winding tap terminals.

[0038] The low-vol...

Embodiment 2

[0046] This embodiment provides a monitoring method utilizing the monitoring system described in Embodiment 1, the steps of which are as follows:

[0047] When measuring temperature, the optical fiber temperature measurement decoding module generates an excitation signal and transmits it to the phosphor at the temperature measurement point through the temperature-resistant optical fiber; after receiving the excitation, the phosphor radiates fluorescence energy, which is transmitted back to the optical fiber temperature measurement decoding through the temperature-resistant optical fiber module;

[0048] Different ambient temperatures have different fluorescence lifetimes. The optical fiber temperature measurement decoding module obtains the temperature information at the current temperature measurement point by measuring the life span of the fluorescent signal transmitted back in the reverse direction; the optical fiber temperature measurement decoding module outputs the magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com