Granular compound feed for fattening beef cattle and preparation method thereof

A technology of compound feed and pellets, which is applied in the field of cattle feed, can solve the problems of long breeding time of beef cattle, poor fattening effect, low feed conversion rate, etc., to reduce the incidence of gastrointestinal diseases, improve disease resistance, and make it easier to digest absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

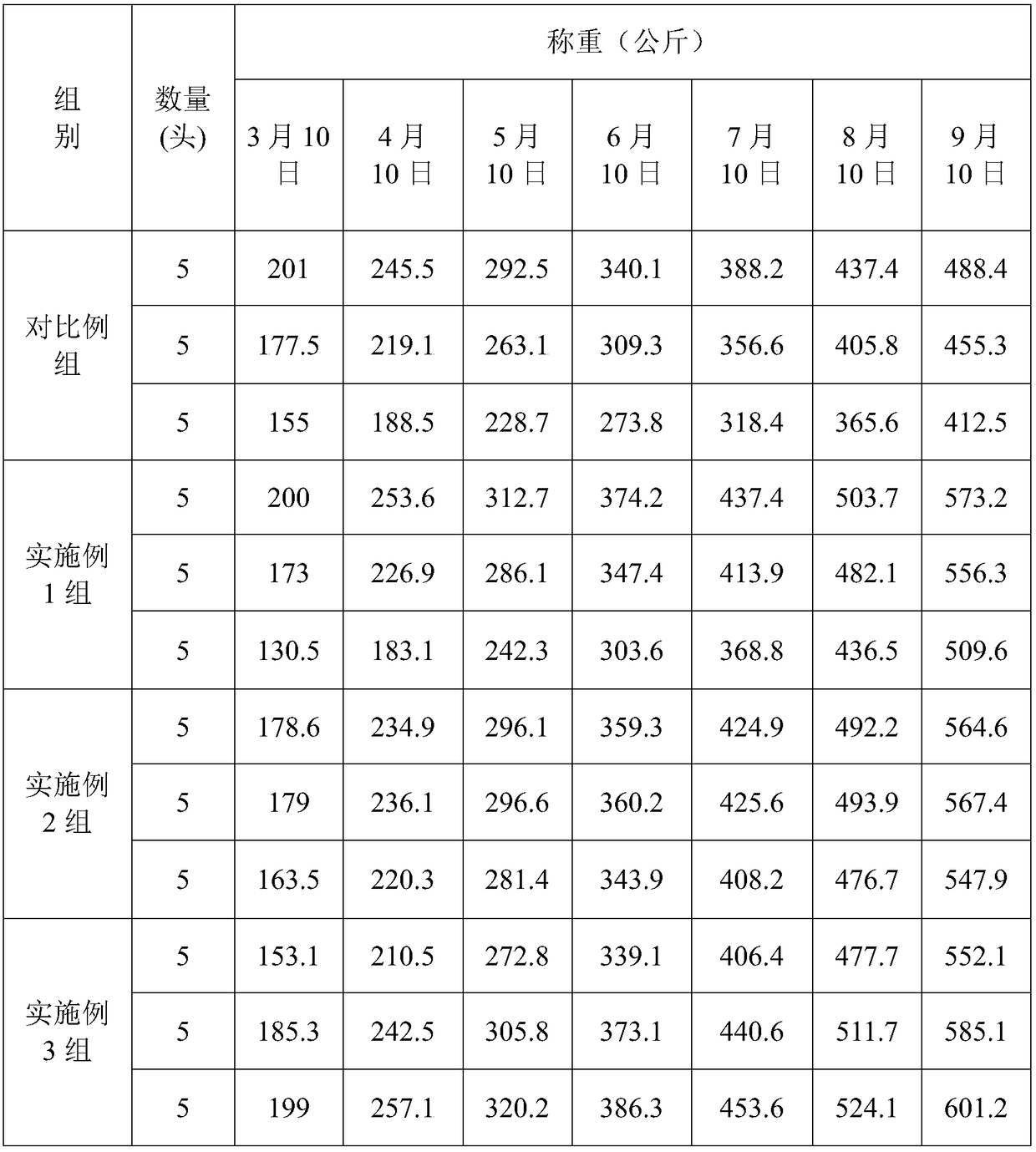

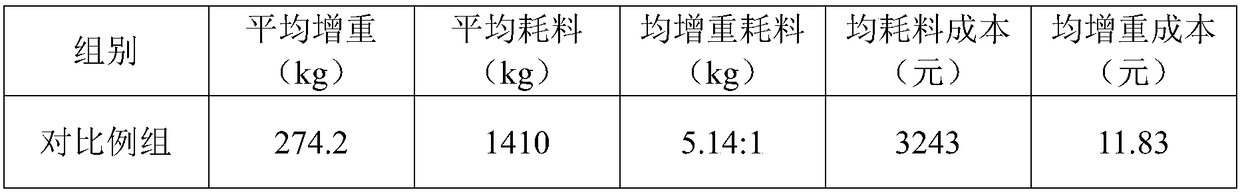

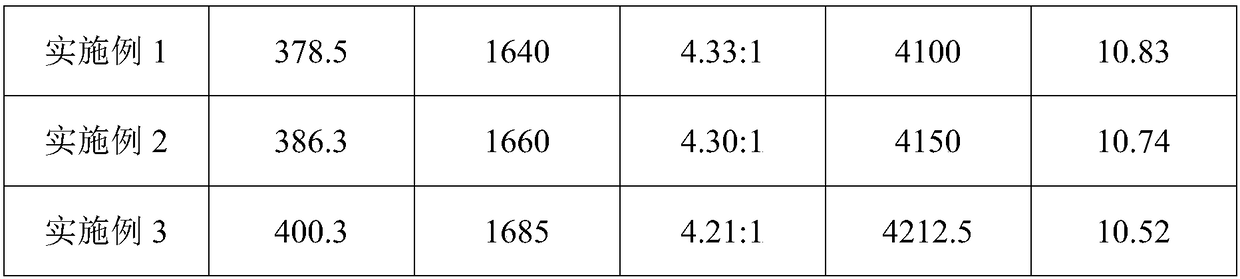

Examples

Embodiment 1

[0031] A granular compound feed for beef cattle fattening is prepared through the following steps:

[0032] S1: corn raw material processing, putting corn into a hammer mill with a sieve plate aperture of 6 mm for crushing, and then weighing 30 parts by weight through a batching scale according to the formula ratio to obtain crushed material A;

[0033] S2: wheat raw material processing, the wheat is put into a hammer mill with a sieve plate aperture of 3 mm for crushing, and then 15 parts by weight are weighed by a batching scale according to the formula ratio to obtain crushed material B;

[0034] S3: Sunflower seed meal raw material processing, put the sunflower seed meal into a hammer mill with a sieve plate aperture of 4 mm for crushing, and then weigh 5 parts by weight through a batching scale according to the formula ratio to obtain crushed material C;

[0035] S4: barley germ root raw material processing, put the barley germ root into a hammer mill with a sieve plate a...

Embodiment 2

[0042] A granular compound feed for beef cattle fattening is prepared through the following steps:

[0043] S1: corn raw material processing, putting corn into a hammer mill with a sieve plate aperture of 6 mm for crushing, and then weighing 40 parts by weight through a batching scale according to the formula ratio to obtain crushed material A;

[0044] S2: Wheat raw material processing, the wheat is put into a hammer mill with a sieve plate aperture of 3 mm for crushing, and then 5 parts by weight are weighed through a batching scale according to the formula ratio to obtain crushed material B;

[0045] S3: sunflower seed meal raw material processing, put the sunflower seed meal into a hammer mill with a sieve plate aperture of 4 mm for crushing, and then weigh 8 parts by weight through a batching scale according to the formula ratio to obtain crushed material C;

[0046] S4: Barley malt root raw material processing, put the barley malt root into a hammer mill with a sieve pla...

Embodiment 3

[0053] A granular compound feed for beef cattle fattening is prepared through the following steps:

[0054] S1, corn raw material processing, putting corn into a hammer mill with a sieve plate aperture of 6 mm for pulverization, and then weighing 35 parts by weight through a batching scale according to the formula ratio, to obtain pulverized material A;

[0055] S2: Wheat raw material processing, putting wheat into a hammer mill with a sieve plate aperture of 3 mm for crushing, and then weighing 10 parts by weight through a batching scale according to the formula ratio to obtain crushed material B;

[0056] S3: sunflower seed meal raw material processing, put the sunflower seed meal into a hammer mill with a sieve plate aperture of 4 mm for crushing, and then weigh 10 parts by weight through a batching scale according to the formula ratio to obtain crushed material C;

[0057] S4: Barley malt root raw material processing, put the barley malt root into a hammer mill with a siev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com