Calcium gluconate-L-calcium lactate oral liquid and preparation method thereof

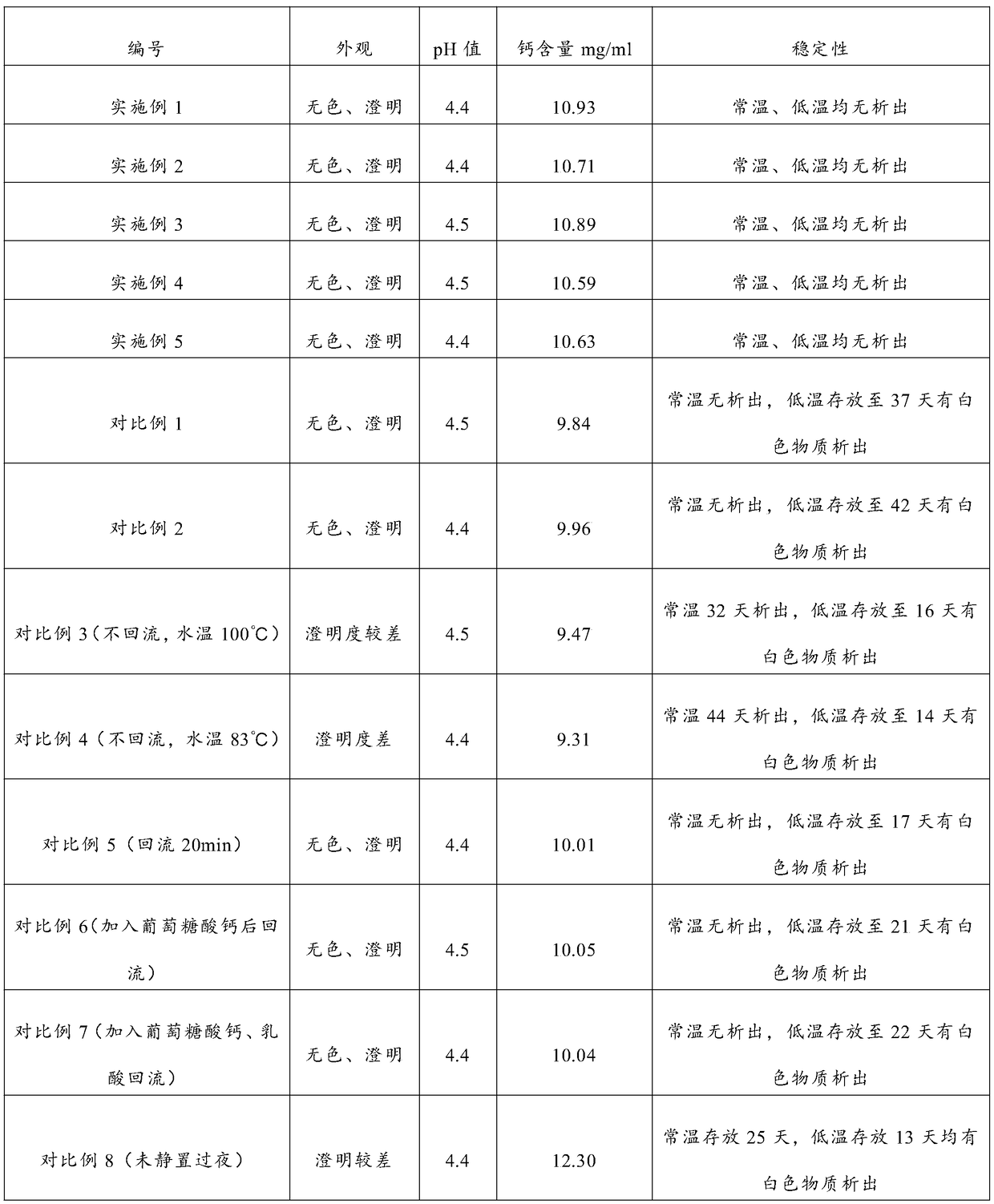

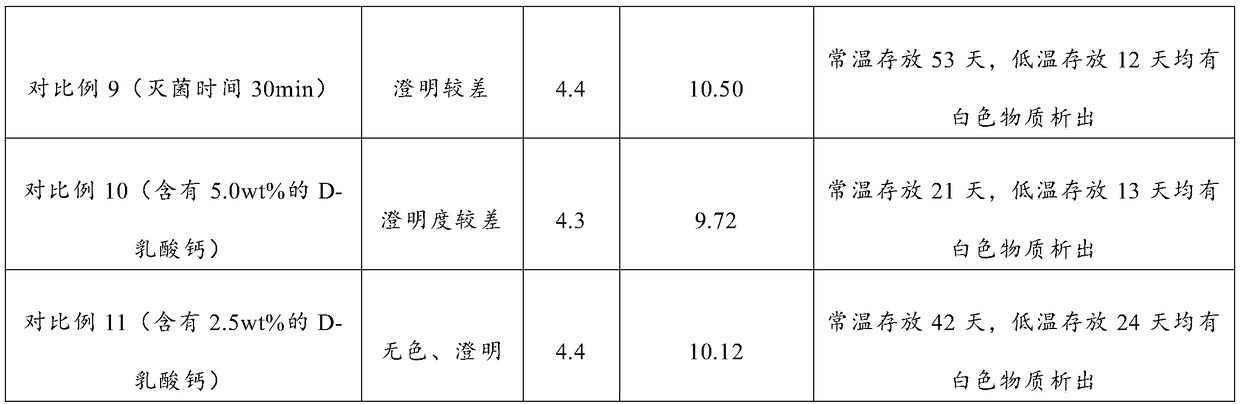

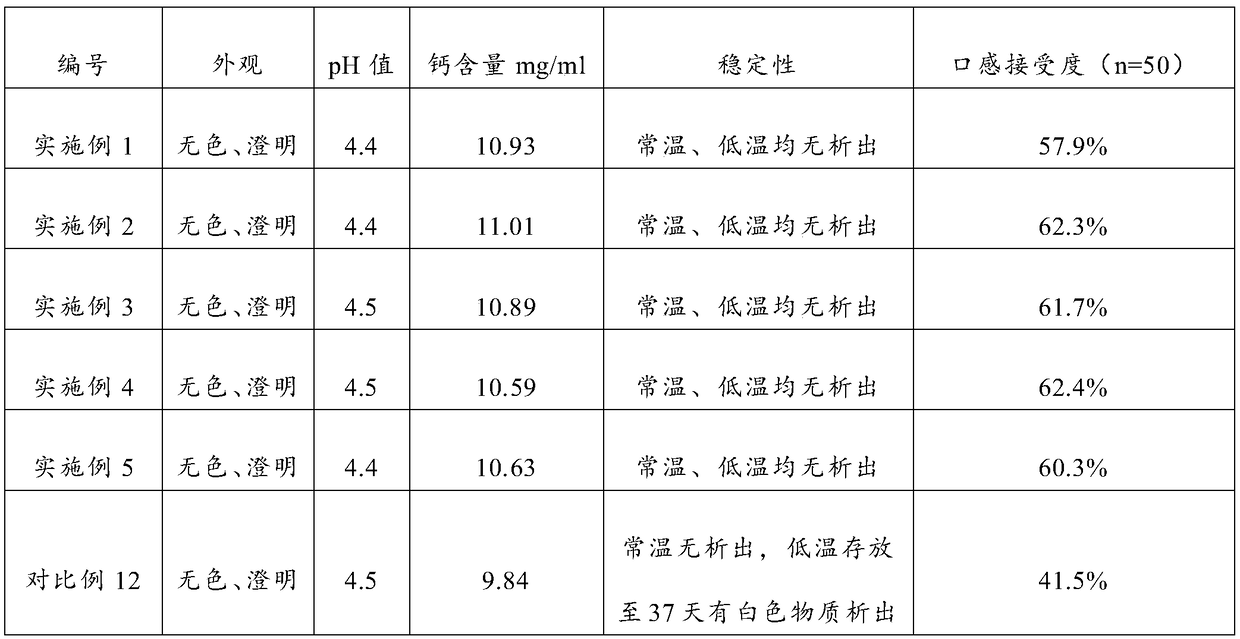

A technology of calcium lactate oral liquid and calcium gluconate, applied in the field of medicine, can solve the problems of low calcium content, low storage stability, easy crystallization and precipitation of calcium gluconate oral liquid, etc. effect of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Quantitatively weigh 1000ml of purified water and place it in a reflux tank, heat and boil to 100°C, then continue to heat and reflux at 100°C for 30min, separate 200ml of boiled purified water for later use;

[0039] (2) Weigh 53.01g of calcium gluconate, 3.80g of lactic acid and 43.50g of L-calcium lactate, and slowly add them to the above-mentioned reflux tank successively under constant stirring, stir evenly, continue heating and reflux at 100°C for 30min, after reflux Stop heating, pass circulating water to cool down to 34°C, and prepare medicinal liquid, wherein, the content of D-calcium lactate in L-calcium lactate is 0.5wt%;

[0040] (3) Take the freshly boiled purified water separated from step (1) and stir to cool down to 60°C, add 0.24g of sucralose, stir to fully dissolve it, add it to the above-mentioned reflux tank, stir evenly, and then add to the above-mentioned reflux tank Freshly boiled purified water cooled to 37°C, dilute the solution in the refl...

Embodiment 2

[0043] (1) Quantitatively weigh 1050ml of purified water and place it in a reflux tank, heat and boil to 100°C, then continue to heat and reflux at 100°C for 50min, separate 150ml of boiled purified water for later use;

[0044] (2) Weigh 50.01g of calcium gluconate, 3.98g of lactic acid and 44.50g of L-calcium lactate, slowly add them to the above-mentioned reflux tank in turn under continuous stirring, stir evenly, continue heating and reflux at 100°C for 40min, after the reflux Stop heating, cool down to 40°C through circulating water, and prepare a medicinal solution, wherein the content of D-calcium lactate in L-calcium lactate is 1.5wt%;

[0045] (3) Take the freshly boiled purified water separated from step (1) and stir to cool down to 55°C, add 0.20 g of sucralose, stir to fully dissolve it, add it to the above-mentioned reflux tank, stir evenly, and then add to the above-mentioned reflux tank Freshly boiled purified water (30-40) cooled to 32°C, dilute the solution in...

Embodiment 3

[0048] (1) Quantitatively weigh 950ml of purified water and place it in a reflux tank, heat and boil to 100°C, then continue to heat and reflux at 100°C for 40min, separate 300ml of boiled purified water for later use;

[0049](2) Weigh 55.01g of calcium gluconate, 3.50g of lactic acid and 40.50g of L-calcium lactate, slowly add them to the above-mentioned reflux tank in turn under constant stirring, stir evenly, continue heating and reflux at 100°C for 50min, after the reflux Stop heating, pass circulating water to cool down to 40°C, and prepare medicinal solution, wherein the content of D-calcium lactate in L-calcium lactate is 1.0wt%;

[0050] (3) Take the freshly boiled purified water separated from step (1) and stir to cool down to 65°C, add 0.28g of sucralose, stir to fully dissolve it, add it to the above-mentioned reflux tank, stir evenly, and then add to the above-mentioned reflux tank Freshly boiled purified water cooled to 30°C, dilute the solution in the reflux tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com