Preparation method and application of PAMs (natural plant antimicrobial solution) hydrogel patch

A hydrogel patch, natural plant technology, applied in the direction of topical antibacterial agents, plant/algae/fungus/moss ingredients, antibacterial drugs, etc. and other problems, to achieve the effect of good skin adhesion, avoiding secondary damage, and not polluting clothes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The hydrogel patch includes the following raw materials in parts by weight: 15 parts of glycerin, 2 parts of NP-700, 0.2 parts of aluminum glycolate, 13.6 parts of distilled water, 0.1 part of tartaric acid, 1.5 parts of azone, 1.5 parts of propylene glycol, 0.25 parts of SDS, and PAMs 15.85 parts;

[0046] The preparation method of hydrogel patch, comprises the following steps:

[0047] S1. Disperse NP-700 and aluminum glycolate in glycerin under stirring conditions to form phase A;

[0048] S2, dispersing tartaric acid, PAMs, azone, propylene glycol, and SDS in water under stirring conditions to form phase B;

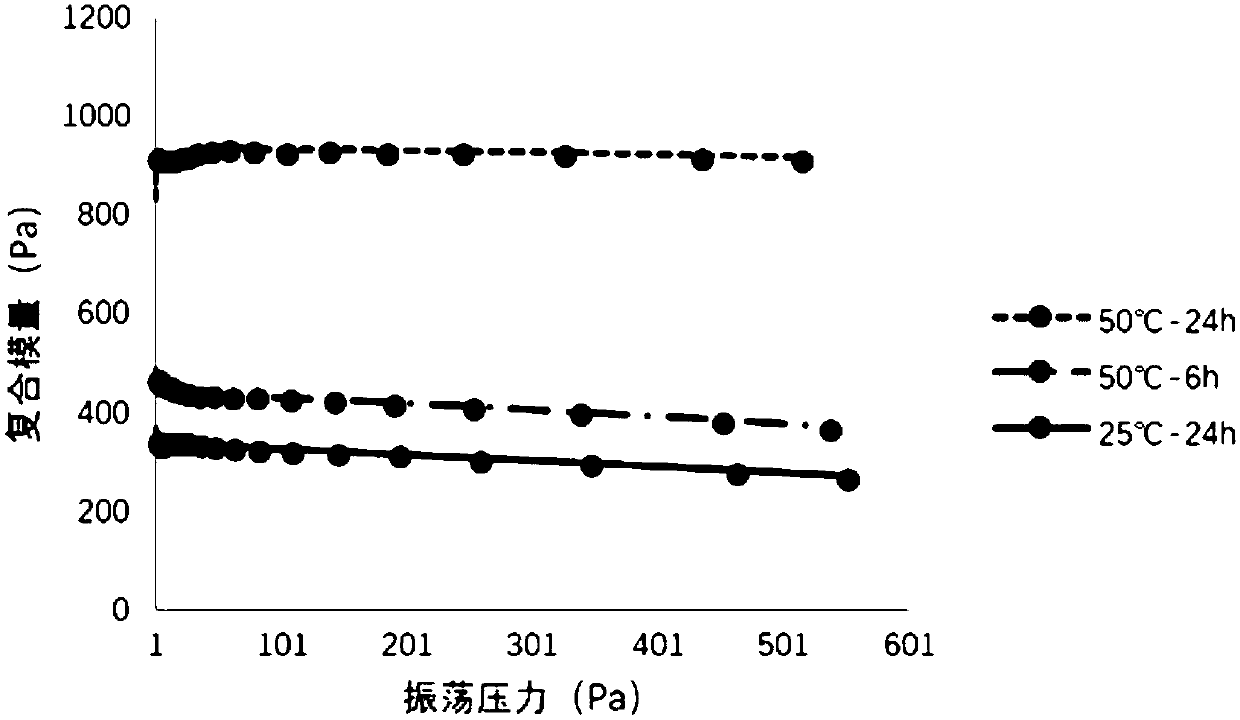

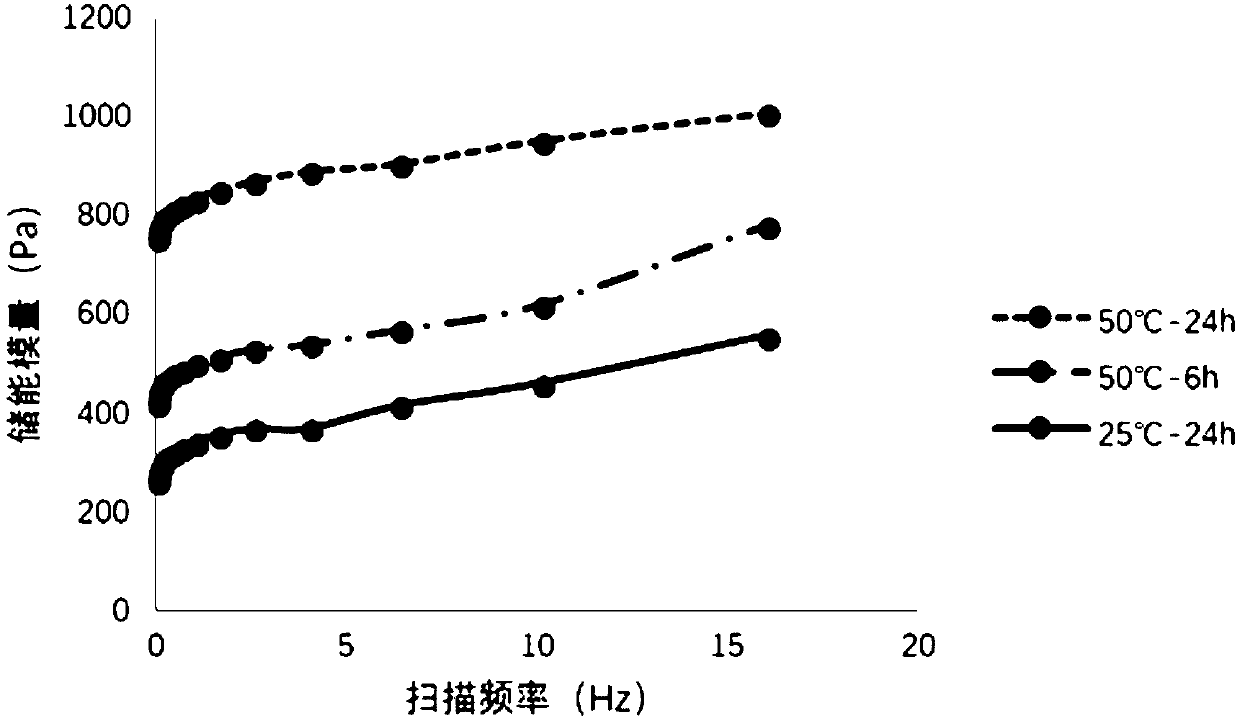

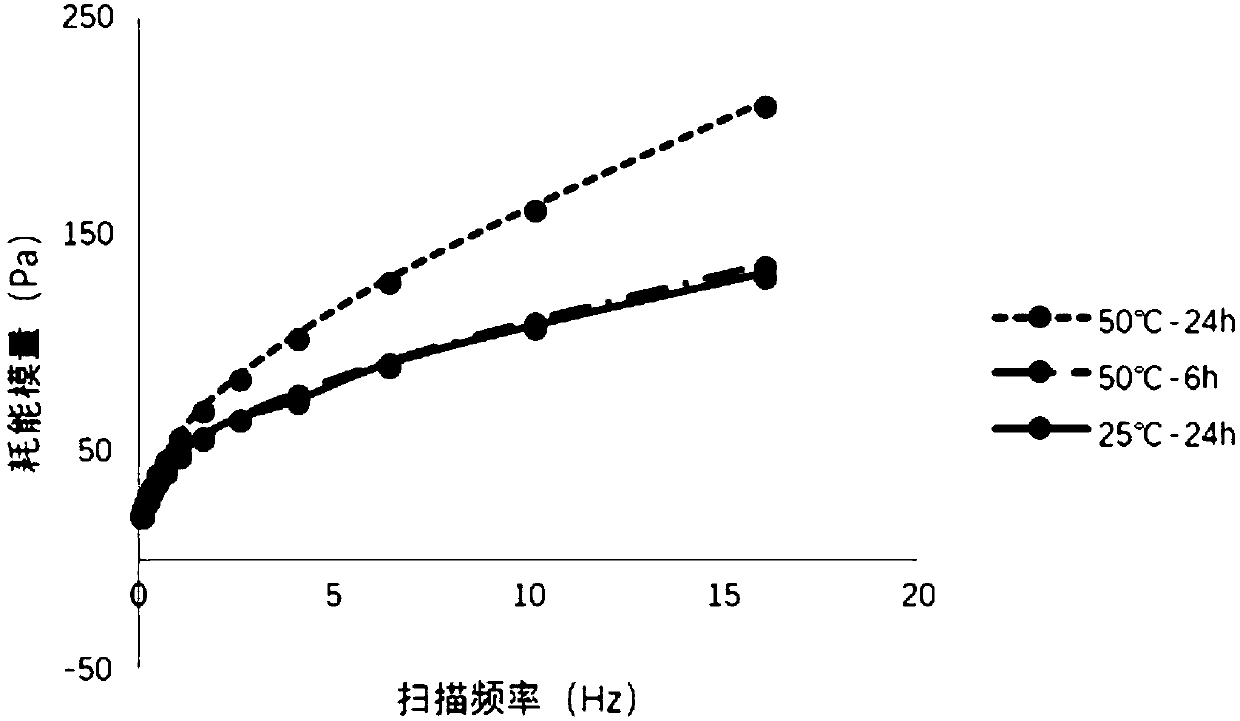

[0049] S3, then add phase B to phase A, stir evenly, put it in an incubator, adjust the temperature to 45°C, keep it warm for 30 hours, take it out and let it stand at room temperature for 1d to obtain the hydrogel patch;

[0050] Wherein, the PAMs include safflower, rue, comfrey, echinacea, and ethanol with a mass volume ratio of 20g:10g:20g:20g:1L;

[0051...

Embodiment 2

[0056] The hydrogel patch includes the following raw materials in parts by weight: 30 parts of glycerin, 4 parts of NP-700, 0.4 parts of aluminum glycylate, 27.2 parts of distilled water, 0.2 parts of tartaric acid, 3 parts of azone, 3 parts of propylene glycol, 0.5 parts of SDS, and 31.7 parts of PAMs;

[0057] The preparation method of hydrogel patch, comprises the following steps:

[0058] S1. Disperse NP-700 and aluminum glycolate in glycerin under stirring conditions to form phase A;

[0059] S2, dispersing tartaric acid, PAMs, azone, propylene glycol, and SDS in water under stirring conditions to form phase B;

[0060] S3, then add phase B to phase A, stir evenly, place in an incubator, adjust the temperature to 50°C, keep warm for 24 hours, take it out and let it stand at room temperature for 2 days to obtain a hydrogel patch;

[0061] Wherein, the PAMs include safflower, rue, comfrey, echinacea, and ethanol with a mass volume ratio of 30g:15g:25g:30g:1L;

[0062] Th...

Embodiment 3

[0067] The hydrogel patch includes the following raw materials in parts by weight: 45 parts of glycerin, 6 parts of NP-700, 0.6 parts of aluminum glycolate, 40.7 parts of distilled water, 0.3 parts of tartaric acid, 4.5 parts of azone, 4.5 parts of propylene glycol, 0.75 parts of SDS, and PAMs 47.55 parts;

[0068] The preparation method of hydrogel patch, comprises the following steps:

[0069] S1. Disperse NP-700 and aluminum glycolate in glycerin under stirring conditions to form phase A;

[0070] S2, dispersing tartaric acid, PAMs, azone, propylene glycol, and SDS in water under stirring conditions to form phase B;

[0071] S3. Then add phase B to phase A, stir evenly, place in an incubator, adjust the temperature to 55°C, keep warm for 18 hours, take it out and let it stand for 3 days at room temperature to obtain a hydrogel patch;

[0072] Wherein, the PAMs include safflower, rue, comfrey, echinacea, and ethanol with a mass volume ratio of 40g:20g:30g:40g:1L;

[0073]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com