Acid gas wet method acid making technology combined with semidry method tail gas desulfurization

A combination of acid gas and technology, applied in the direction of sulfur compounds, separation methods, chemical instruments and methods, etc., can solve the problems affecting the normal and stable operation of the desulfurization system, equipment corrosion, and content exceeding the standard, so as to achieve good economic and environmental benefits and cost The effect of low and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment, but protection scope of the present invention is not limited thereto, and any obvious improvement or change of above-mentioned embodiment that those skilled in the art make, all can not go beyond the design of the present invention and the claims scope of protection.

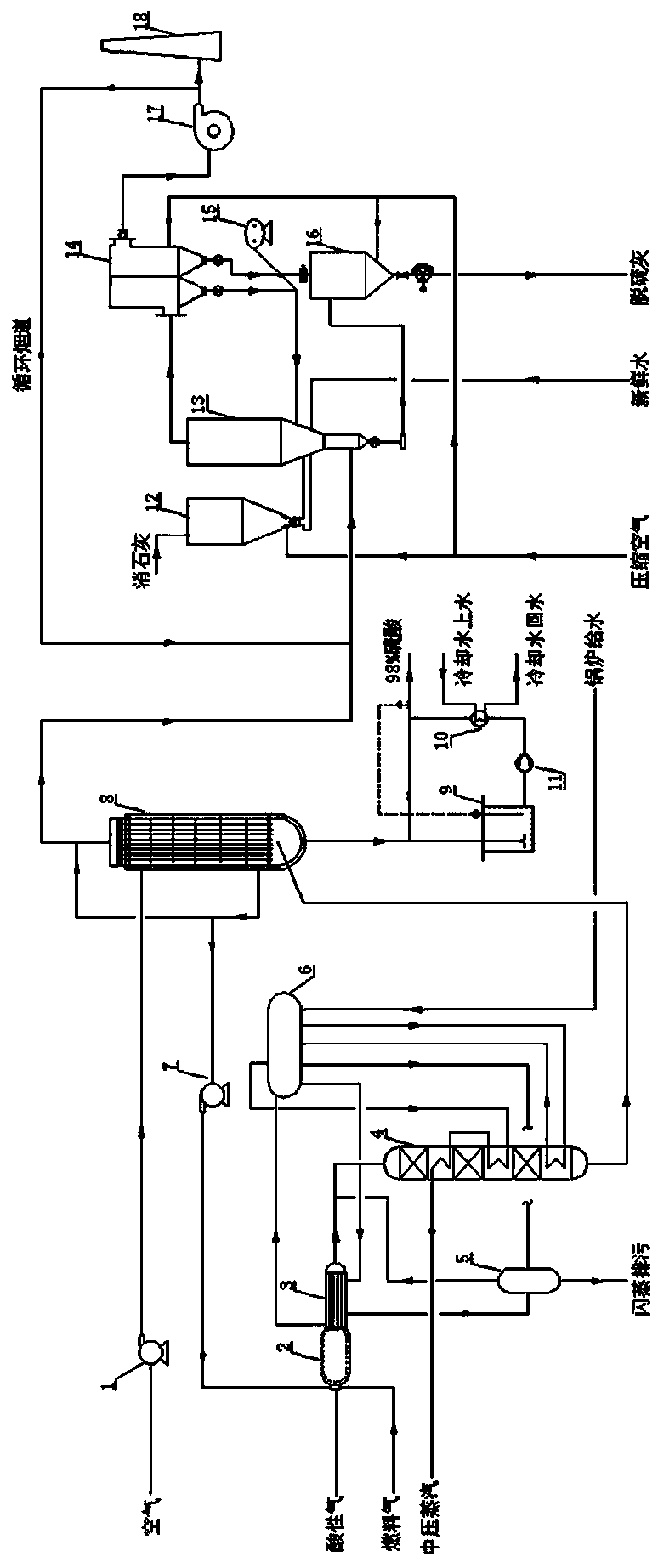

[0025] As shown in the figure: a sour gas wet acid production process combined with semi-dry tail gas desulfurization, which specifically includes the following steps:

[0026] (1) Acid gas wet method for acid production:

[0027] Contains H 2 The acid gas of S, the fuel gas from the boundary area, and the excess hot air from the secondary fan 7 enter the acid gas combustion furnace 2, and the combustion temperature is controlled at 900-1300°C to ensure the H in the acid gas 2 S and other sulfur compounds are completely converted to SO 2 , and then the process gas is cooled to 390-420°C through the acid gas waste heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com