Preparation method of low-antimony niobium oxide and preparation method of low-antimony tantalum oxide

A technology of niobium oxide and niobium hydroxide, which is applied in chemical instruments and methods, inorganic chemistry, tantalum compounds, etc., can solve the problems of difficult industrial production, large ammonium consumption, and difficult industrial application, and achieve easy industrial production and high efficiency. The effect of removal and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

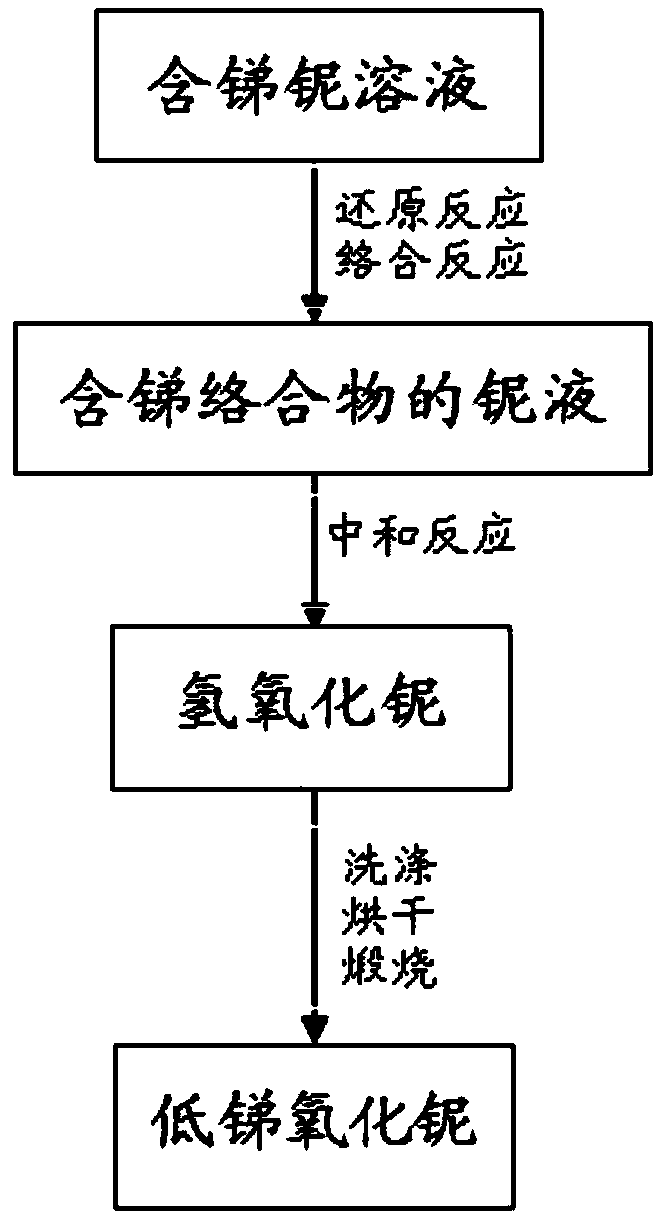

[0026] The invention provides a method for preparing low-antimony niobium oxide, comprising the following steps:

[0027] (1) mixing the antimony-niobium solution with a reducing agent to carry out a reduction reaction; then mixing the feed solution after the reduction reaction with a complexing agent to carry out a complexation reaction to obtain a niobium liquid containing an antimony complex;

[0028] (2) the niobium liquid of described step (1) is mixed with ammonia gas or liquefied ammonia, carry out neutralization reaction, generate niobium hydroxide precipitation, and antimony exists in the solution with complex form;

[0029] (3) Filtering, washing, drying and calcining the niobium hydroxide in the step (2) in sequence to obtain low-antimony niobium oxide.

[0030] In the following specific embodiments, unless otherwise specified, the reagents used are commercially available products well known to those skilled in the art.

[0031] The invention mixes the solution con...

Embodiment 1

[0054] The chemical composition of the tantalum-niobium ore is shown in Table 1:

[0055] Table 1 Chemical composition of tantalum-niobium ore

[0056] element

Ta

Nb

Sb

Mass content

4.1%

31.2%

0.12%

[0057] Mix tantalum and niobium ore with hydrofluoric acid and sulfuric acid, carry out acid leaching, extraction and stripping, and obtain antimony-niobium solution and antimony-tantalum solution, wherein the content of niobium in the antimony-niobium solution and the tantalum in the antimony-tantalum solution are content is listed in Table 2.

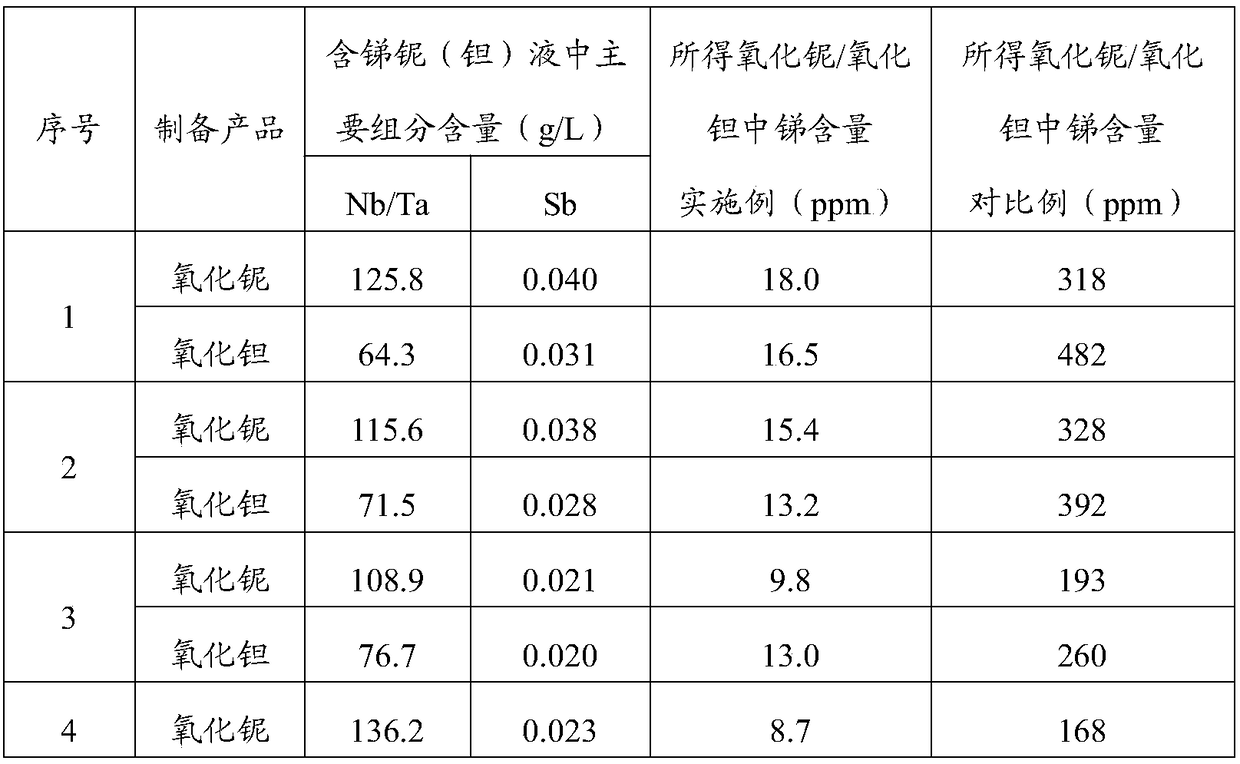

[0058] according to figure 1 The schematic flow chart shown prepares low-antimony niobium oxide: take 3m niobium solution containing antimony 3 In the neutralization tank, add citric acid in an amount of 1kg / L, react at 60°C for 30min, then add triethanolamine in an amount of 1kg / L, react at 80°C for 6h, and obtain a niobium solution containing an antimony complex; Adjust the pH value of the ...

Embodiment 2

[0061] Take 3m niobium solution containing antimony 3 In the neutralization tank, add citric acid in an amount of 0.5kg / L, react at 60°C for 30min, then add triethanolamine in an amount of 0.5kg / L, react at 85°C for 6h, and obtain the niobium containing antimony complex solution; adjust the pH value of the niobium-containing solution to 9 with ammonia water, filter, wash, dry and calcinate after the precipitation is complete, wherein the calcining conditions are: calcining at 850°C for 1.5h to obtain low-antimony niobium oxide.

[0062] Get embodiment 1 gained to contain antimony tantalum liquid 3m 3 In the neutralization tank, add citric acid in an amount of 0.5kg / L, react at 60°C for 30min, then add triethanolamine in an amount of 0.5kg / L, react at 85°C for 6h, and obtain antimony complex-containing tantalum solution; adjust the pH value of the tantalum-containing solution to 9 with ammonia water, filter, wash, dry and calcinate after the precipitation is complete, wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com