High-difficulty wastewater treatment device

A wastewater treatment and equipment technology, applied in water/sewage treatment, illuminated water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of limited degradability of difficult wastewater, complicated use and maintenance, high energy consumption of equipment, etc., to achieve the best results Good, increased contact area, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

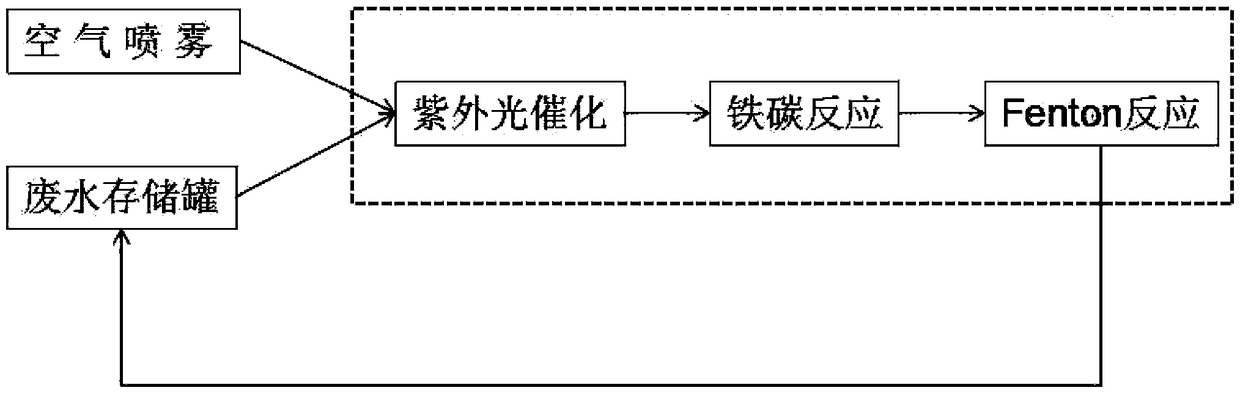

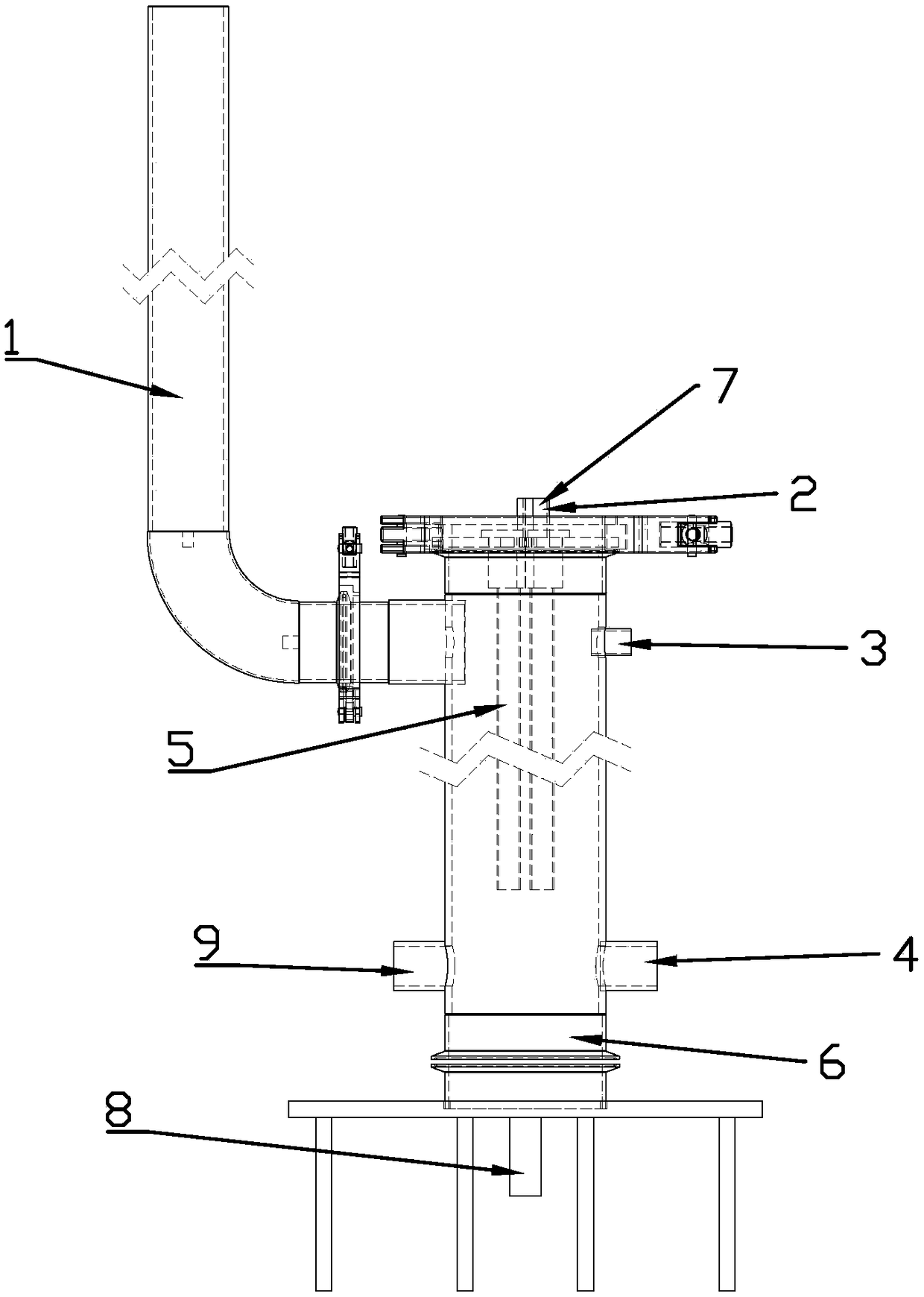

[0022] Such as figure 1 , 2 As shown, a kind of high-difficulty wastewater treatment equipment of the present invention comprises a wastewater storage tank and a wastewater treatment device; the wastewater treatment device includes a closed reaction vessel, a catalyst attached to the inner wall of the vessel, an ultraviolet lamp 5 on the top of the vessel, and is arranged in a closed reaction vessel. The water storage tank 6 at the bottom of the container and the iron-carbon filler placed at the bottom of the water storage tank 6, the liquid inlet 7 and the air inlet 3 are arranged on the top of the closed reaction container, and the liquid inlet 7 is connected to the raw water storage tank through a hose, A spray nozzle 2 is arranged at the liquid inlet 7 .

[0023] Described ultraviolet lamp 5 is an ozone type ultraviolet lamp, and described ultraviolet lamp 5 is set to a plurality of, present embodiment preferably 2, and the wavelength that described ultraviolet lamp 5 pro...

Embodiment 2

[0050] Such as figure 1 , 2 As shown, a kind of high-difficulty wastewater treatment equipment of the present invention comprises a wastewater storage tank and a wastewater treatment device; the wastewater treatment device includes a closed reaction vessel, a catalyst attached to the inner wall of the vessel, an ultraviolet lamp 5 on the top of the vessel, and is arranged in a closed reaction vessel. The water storage tank 6 at the bottom of the container and the iron-carbon filler placed at the bottom of the water storage tank 6, the liquid inlet 7 and the air inlet 3 are arranged on the top of the closed reaction container, and the liquid inlet 7 is connected to the raw water storage tank through a hose, A spray nozzle 2 is arranged at the liquid inlet 7 .

[0051] Described ultraviolet lamp 5 is an ozone type ultraviolet lamp, and described ultraviolet lamp 5 is set to a plurality of, present embodiment preferably 2, and the wavelength that described ultraviolet lamp 5 pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com