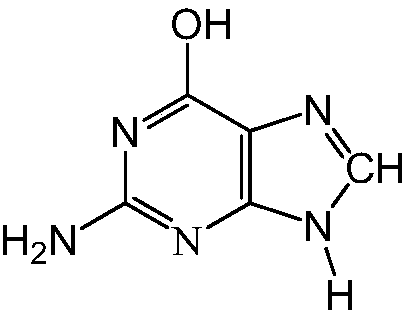

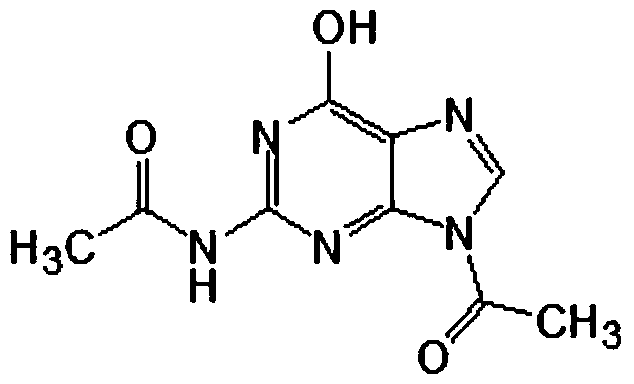

Method for recovering guanine from centrifugal mother liquor of 2, 9-diacetyl guanine

A technology of diacetylguanine and centrifugal mother liquor, applied in the field of guanine recovery, can solve the problems of reducing the utilization rate of raw materials, a large amount of solid waste, waste of useful resources, etc., and achieve effective recycling, realization of resources, and improvement of raw material utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

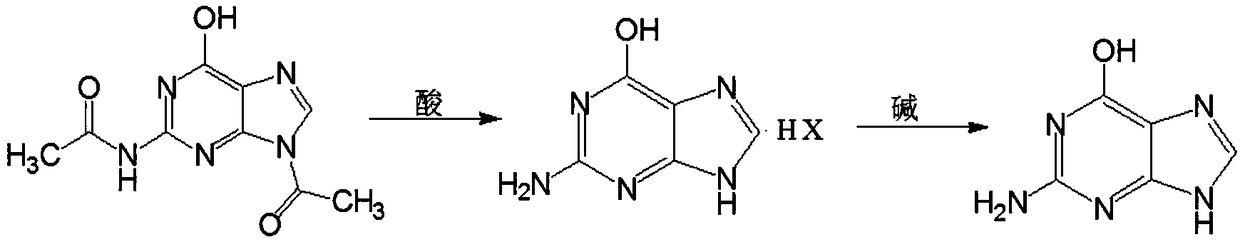

Method used

Image

Examples

Embodiment 1

[0034] Put 50g of guanine, 250g of acetic anhydride, 90g of acetic acid and 0.1g of PTS into a clean and dry 500mL three-neck flask, start stirring, start heating to reflux, react for 10 hours, and centrifuge to obtain the centrifuged mother liquor. The centrifuged mother liquor is distilled and concentrated, and the bottom material is concentrated Add 200 ml of dilute hydrochloric acid with a concentration of 10% by mass, heat until dissolved, then add 3 g of activated carbon, heat up and reflux for 2 hours for hydrolysis and decolorization, filter while it is hot, cool the filtrate to 15°C, cool and crystallize, filter to obtain bird Purine hydrochloride wet product, then add guanine hydrochloride to 80 ml of sodium hydroxide solution with a concentration of 5% by mass, heat up to dissolve, add 0.4 g of activated carbon, heat up and reflux for 30 minutes for decolorization, and filter while hot , the filtrate was acidified by adding concentrated hydrochloric acid to adjust th...

Embodiment 2

[0036] Put 50g of guanine, 250g of acetic anhydride, 90g of acetic acid and 0.1g of PTS into a clean and dry 500mL three-neck flask, start stirring, start heating to reflux, react for 10 hours, and centrifuge to obtain the centrifuged mother liquor. The centrifuged mother liquor is distilled and concentrated, and the bottom material is concentrated Add 200 ml of dilute sulfuric acid with a concentration of 10% by mass, heat to dissolve, then add 3 g of activated carbon, heat up and reflux for 2.5 hours for hydrolysis and decolorization, filter while it is hot, cool the filtrate to 12 ° C, cool and crystallize, filter to obtain bird Purine sulfate wet product, then guanine hydrochloride is added to 80 ml of sodium carbonate solution with a concentration of 8% by mass, heated and dissolved, added 0.4 g of activated carbon, heated and refluxed for 30 minutes for decolorization, filtered while hot, The filtrate was acidified by adding sulfuric acid with a mass percentage concentrat...

Embodiment 3

[0038] Put 50g of guanine, 250g of acetic anhydride, 90g of acetic acid and 0.1g of PTS into a clean and dry 500mL three-neck flask, start stirring, start heating to reflux, react for 10 hours, and centrifuge to obtain the centrifuged mother liquor. The centrifuged mother liquor is distilled and concentrated, and the bottom material is concentrated Add 300 ml of hydrochloric acid with a mass percentage concentration of 12%, heat to dissolve, then add 4 g of activated carbon, heat up and reflux for 3 hours for decolorization, filter while hot, cool the filtrate to 10°C, cool and crystallize, filter to obtain guanine Sulphate wet product, then guanine hydrochloride was added to 90 milliliters of potassium hydroxide solution with a concentration of 5% by mass, heated and heated to dissolve, added 0.5 g of activated carbon, heated and refluxed for 30 minutes for decolorization, filtered while hot, The filtrate was acidified by adding concentrated hydrochloric acid to adjust the pH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com