Composite rubber material with electromagnetic shielding function

A composite rubber and electromagnetic shielding technology, which is applied in the fields of magnetic/electric field shielding, electrical components, textiles and papermaking, etc., can solve the problems of poor mechanical quality and heavy weight of rubber, and achieve good overall quality, long life and corrosion resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

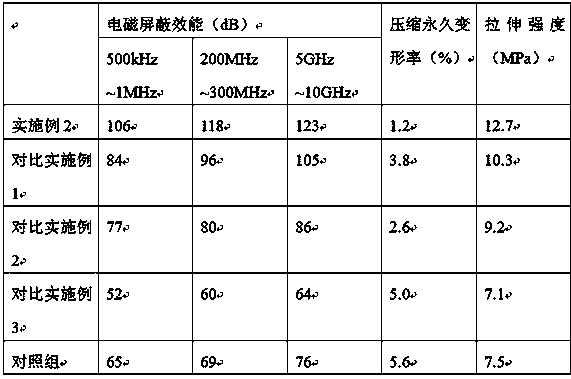

Examples

Embodiment 1

[0029] A composite rubber material with electromagnetic shielding function, made of the following substances by weight:

[0030] 55 parts of nitrile rubber, 10 parts of silicone rubber, 20 parts of natural rubber, 5 parts of fluororubber, 4 parts of stearic acid, 2 parts of sulfur, 5 parts of kaolin, 3 parts of mica powder, 1 part of polyvinyl alcohol, 2 parts of pyrophosphoric acid Sodium, 1 part antioxidant, 0.5 part accelerator, 10 parts modified functional filler.

[0031] Further, both the kaolin and mica powder have been calcined, and the calcining process specifically includes placing the kaolin and mica powder in an environment at a temperature of 820° C. for 1 hour for calcining.

[0032] Further, the antioxidant is antioxidant 245.

[0033] Further, the accelerator is accelerator NA-22.

[0034] Further, the modified functional filler is composed of small particle modified ramie fiber, medium particle modified ramie fiber and large particle modified ramie fiber, an...

Embodiment 2

[0045] A composite rubber material with electromagnetic shielding function, made of the following substances by weight:

[0046] 58 parts of nitrile rubber, 13 parts of silicone rubber, 22 parts of natural rubber, 8 parts of fluororubber, 5 parts of stearic acid, 3 parts of sulfur, 6 parts of kaolin, 5 parts of mica powder, 2 parts of polyvinyl alcohol, 4 parts of pyrophosphoric acid Sodium, 1.5 parts of antioxidant, 1 part of accelerator, 13 parts of modified functional filler.

[0047] Further, both the kaolin and mica powders have been calcined, and the calcining process specifically includes putting the kaolin and mica powders into an environment with a temperature of 840° C. for 1.5 hours for calcining.

[0048] Further, the antioxidant is antioxidant 626.

[0049] Further, the accelerator is accelerator BZ.

[0050] Further, the modified functional filler is composed of small particle modified ramie fiber, medium particle modified ramie fiber and large particle modifie...

Embodiment 3

[0061] A composite rubber material with electromagnetic shielding function, made of the following substances by weight:

[0062] 60 parts of nitrile rubber, 15 parts of silicone rubber, 25 parts of natural rubber, 10 parts of fluororubber, 6 parts of stearic acid, 4 parts of sulfur, 7 parts of kaolin, 6 parts of mica powder, 3 parts of polyvinyl alcohol, 5 parts of pyrophosphoric acid Sodium, 2 parts of antioxidant, 1.5 parts of accelerator, 15 parts of modified functional filler.

[0063] Further, both the kaolin and mica powders have been calcined, and the calcining process specifically includes putting the kaolin and mica powders into an environment with a temperature of 860° C. for 2 hours for calcining.

[0064] Further, the antioxidant is antioxidant 1010.

[0065] Further, the accelerator is accelerator NS.

[0066] Further, the modified functional filler is composed of small particle modified ramie fiber, medium particle modified ramie fiber and large particle modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com