Preparation method of degradable food packaging film

A food packaging film, ultrasonic cleaning technology, applied in the field of packaging film, can solve the problems of white pollution, and difficult degradation, loss, etc., to achieve the effect of smooth packaging surface, good aesthetics, good antibacterial and anti-oxidative properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

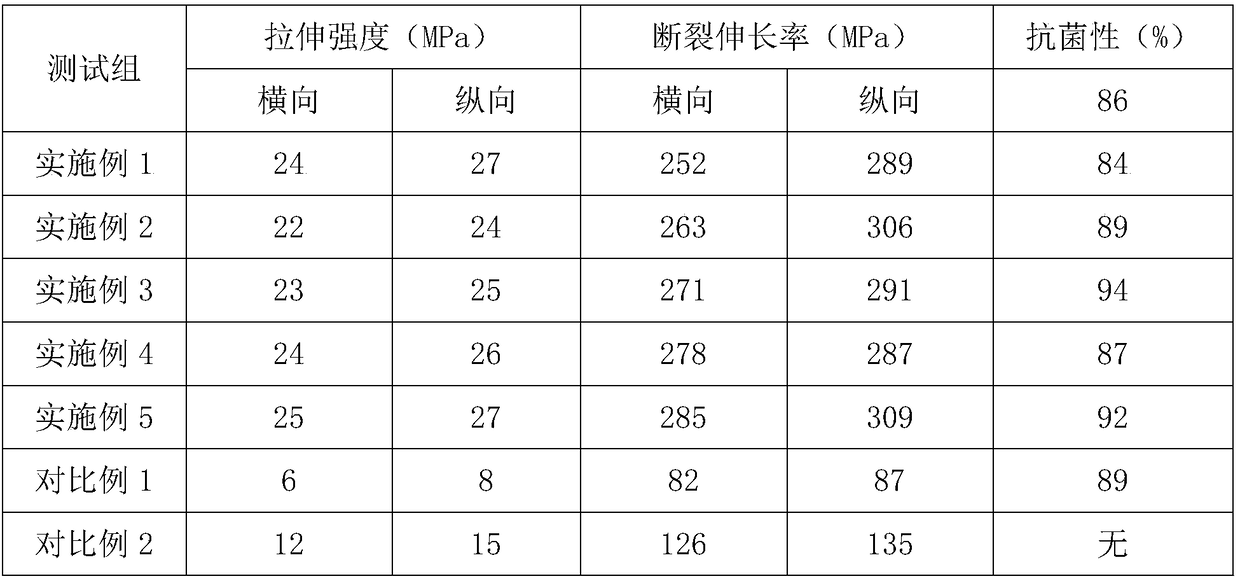

Examples

Embodiment 1

[0031] A preparation method of degradable food packaging film, comprising the following steps:

[0032] (1) Ultrasonic cleaning is carried out on the tea stems, the ultrasonic cleaning power is 300W, and the cleaning time is 4 minutes. After vacuum drying at 60 degrees Celsius, put it into a pulverizer for pulverization, and pass through an 80-mesh sieve to obtain tea powder;

[0033] (2) adding tea powder to 65% ethanol aqueous solution with a mass fraction of 10 times its weight, stirring and mixing evenly, soaking for 1 hour, putting into an ultrasonic extractor and extracting for 80 minutes, filtering to obtain filtrate and filter residue, Repeat the above steps of ultrasonic extraction for the filter residue to extract 2 more times, and combine the filtrates;

[0034] (3) The combined filtrate in step (2) is vacuum-concentrated at 0.06 MPa until the solid content of the concentrated liquid is 35%, then spray-dried, pulverized and passed through a 150-mesh sieve to obtain ...

Embodiment 2

[0048] A preparation method of degradable food packaging film, comprising the following steps:

[0049] (1) Ultrasonic cleaning is performed on the tea stems, the ultrasonic cleaning power is 400W, and the cleaning time is 7 minutes. After vacuum drying at 60 degrees Celsius, put it into a pulverizer for pulverization, and pass through a 150-mesh sieve to obtain tea powder;

[0050](2) adding the tea powder to 65% ethanol aqueous solution with a mass fraction of 15 times its weight, stirring and mixing evenly, soaking for 1 hour, putting it into an ultrasonic extractor and extracting for 90 minutes, filtering to obtain filtrate and filter residue, The filter residue was extracted 4 times by repeating the above steps of ultrasonic extraction, and the filtrate was combined;

[0051] (3) The combined filtrate in step (2) is vacuum-concentrated at 0.08 MPa until the solid content of the concentrated liquid is 42%, then spray-dried, pulverized and passed through a 300-mesh sieve to...

Embodiment 3

[0065] A preparation method of degradable food packaging film, comprising the following steps:

[0066] (1) Ultrasonic cleaning is performed on the tea stalks, the ultrasonic cleaning power is 360W, and the cleaning time is 5 minutes. After vacuum drying at 60 degrees Celsius, put it into a pulverizer for pulverization, and pass through a 100-mesh sieve to obtain tea powder;

[0067] (2) adding the tea powder to 65% ethanol aqueous solution with a mass fraction of 13 times its weight, stirring and mixing evenly, soaking for 1 hour, putting it into an ultrasonic extractor and extracting for 86 minutes, filtering to obtain filtrate and filter residue, The filter residue was repeated for 3 times by repeating the above steps of ultrasonic extraction, and the filtrate was combined;

[0068] (3) The combined filtrate in step (2) is vacuum-concentrated at 0.07 MPa until the solid content of the concentrated liquid is 40%, then spray-dried, pulverized and passed through a 200-mesh sie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com