Preparation method of thickening agent for salt-resisting and high-suspension coating

A technology of high suspension and thickener, applied in the direction of coating, etc., can solve the problems of incapable of weakening the hydration of emulsion particles in water-based coatings, poor suspension stability, poor salt resistance of thickeners, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

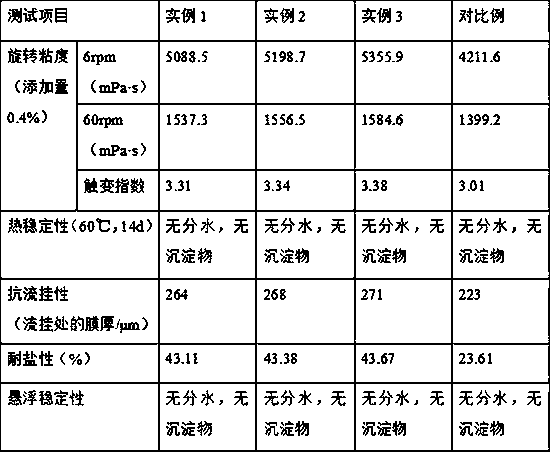

Examples

example 1

[0029] Add 150mL epichlorohydrin to a three-necked flask with a stirrer and a ventilation tube, place the three-necked flask in an ice-water bath, pass trimethylamine gas into the three-necked flask at a ventilation rate of 40mL / min, start the agitator, and Stir at a speed of 1 / min, ventilate for 4 hours, filter and separate to obtain a white solid product, put it in a vacuum drying oven with a set temperature of 70°C, and dry for 6 hours to obtain a cationic etherification agent; add 30 g of hydroxyethyl cellulose to the reactor element, 120mL of sodium hydroxide solution with a mass fraction of 15% and 8 g of cationic etherification agent, stirred for 1 hour to obtain a reaction product, and neutralized the reaction product with 20% hydrochloric acid to obtain a suspension, which was placed in Centrifuge in a high-speed centrifuge at a speed of 2000r / min for 8min, remove the supernatant, collect the sediment in the lower layer, put the sediment in an oven with a set temperatu...

example 2

[0031] Add 155mL of epichlorohydrin to a three-necked flask with a stirrer and a ventilation tube, place the three-necked flask in an ice-water bath, pass trimethylamine gas into the three-necked flask at a ventilation rate of 45mL / min, start the agitator, and Stir at a speed of 1 / min, ventilate and react for 4 hours, filter and separate to obtain a white solid product, put it in a vacuum drying oven with a set temperature of 75°C, and dry for 6 hours to obtain a cationic etherification agent; add 33g of hydroxyethyl cellulose to the reactor element, 130mL of sodium hydroxide solution with a mass fraction of 15% and 9g of cationic etherification agent, stirred and reacted for 1h to obtain a reaction product, neutralized the reaction product with 20% hydrochloric acid to obtain a suspension, and placed the suspension in Centrifuge in a high-speed centrifuge at a speed of 2500r / min for 9min, remove the supernatant, collect the sediment in the lower layer, and dry the sediment in ...

example 3

[0033]Add 160mL of epichlorohydrin to a three-necked flask with a stirrer and a ventilation tube, place the three-necked flask in an ice-water bath, pass trimethylamine gas into the three-necked flask at a ventilation rate of 50mL / min, start the agitator, and Stir at a speed of 1 / min, ventilate and react for 5 hours, filter and separate to obtain a white solid product, put it in a vacuum drying oven with a set temperature of 80°C, and dry for 7 hours to obtain a cationic etherification agent; add 35g of hydroxyethyl cellulose to the reactor element, 140mL of sodium hydroxide solution with a mass fraction of 15% and 10g of cationic etherification agent, stirred and reacted for 2 hours to obtain a reaction product, neutralized the reaction product with 20% hydrochloric acid to obtain a suspension, and placed the suspension in Centrifuge in a high-speed centrifuge at a speed of 3000r / min for 10 minutes, remove the upper layer, collect the lower sediment, put the sediment in an ove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com