Method and equipment for continuous large-scale separation and preparation of D-psicose

A large-scale technology of allulose, applied in the field of continuous large-scale separation and preparation of D-psicose, which can solve problems such as complex components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

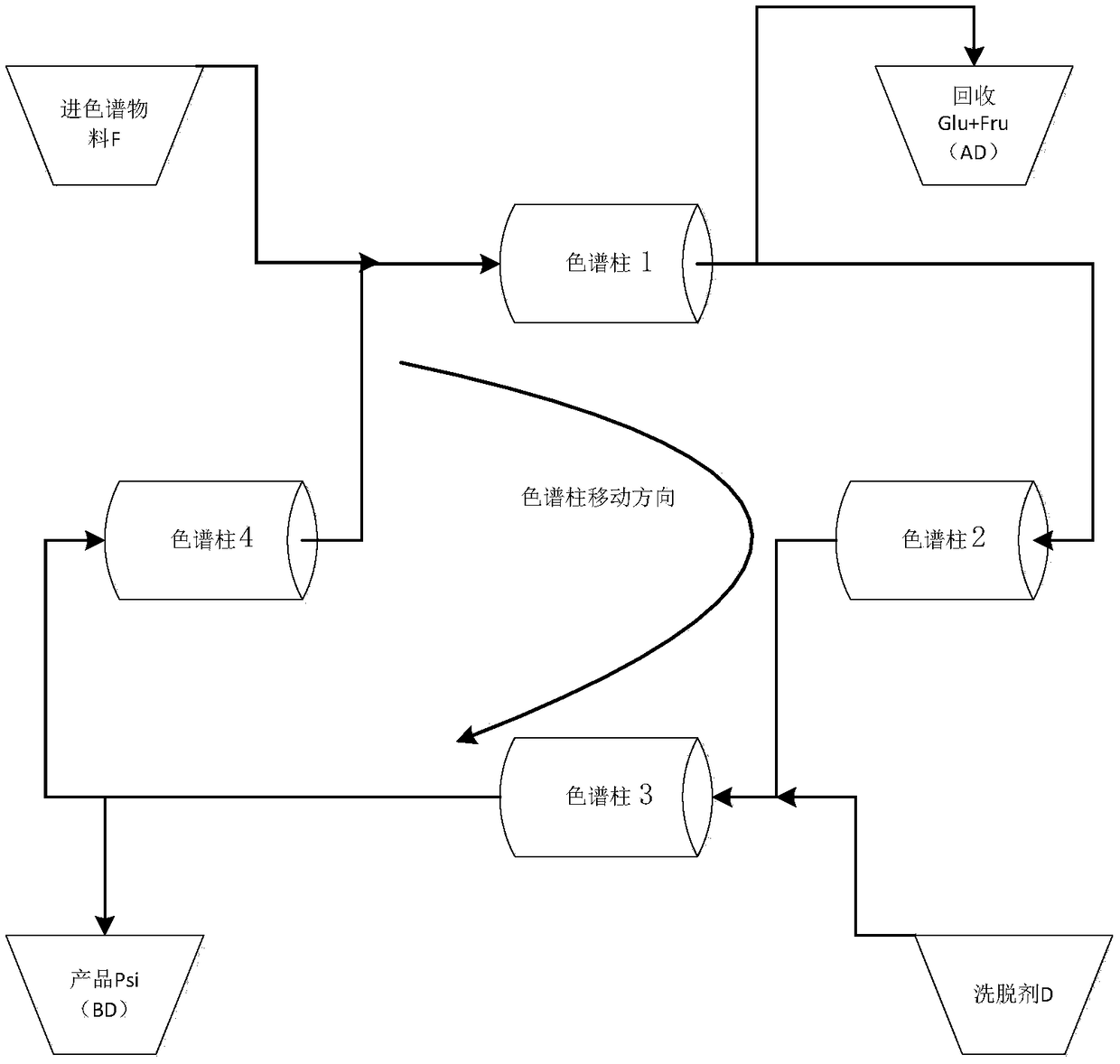

Method used

Image

Examples

Embodiment 1

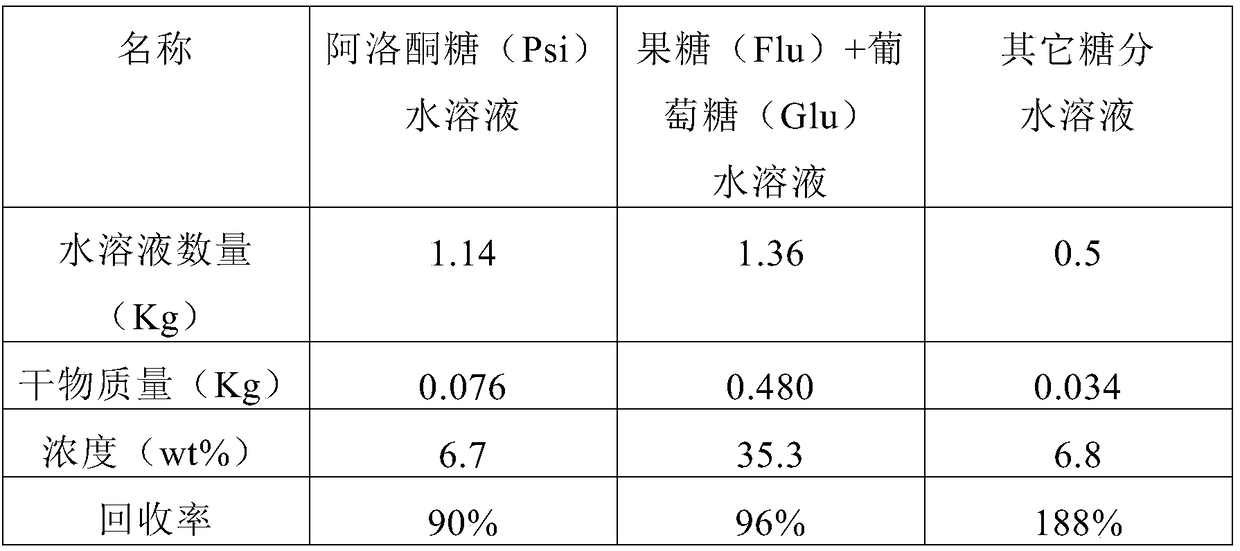

[0120] The allulose aqueous solution obtained from starch as raw material through enzymatic conversion is desalted by ion exchange resin, preheated to 60°C, injected into a chromatographic column with a diameter-to-height ratio of 1:10, and filled with calcium-type cationic chromatographic resin (column length 100cm, diameter 10.0cm, a total of 6), the total amount of resin is 4Kg, the total amount of feed is 1Kg (including 0.084Kg of allulose, 0.252Kg of glucose, 0.246Kg of fructose, and 0.018Kg of other sugars), the column temperature is controlled At 60°C, the feed flow rate is 0.020BV / h, eluted with deionized water, the ratio of material to water is 1.0:2.0, and the elution flow rate is 0.050BV / h. The eluate and residual liquid are collected respectively to obtain Alor Ketose (first discharge liquid, slow component, 0.076Kg), fructose+glucose (second discharge liquid, fast component, 0.48Kg) and residual solution (maltose+isomaltose+maltotriose+polysaccharide+ The aqueous ...

Embodiment 2 to 11

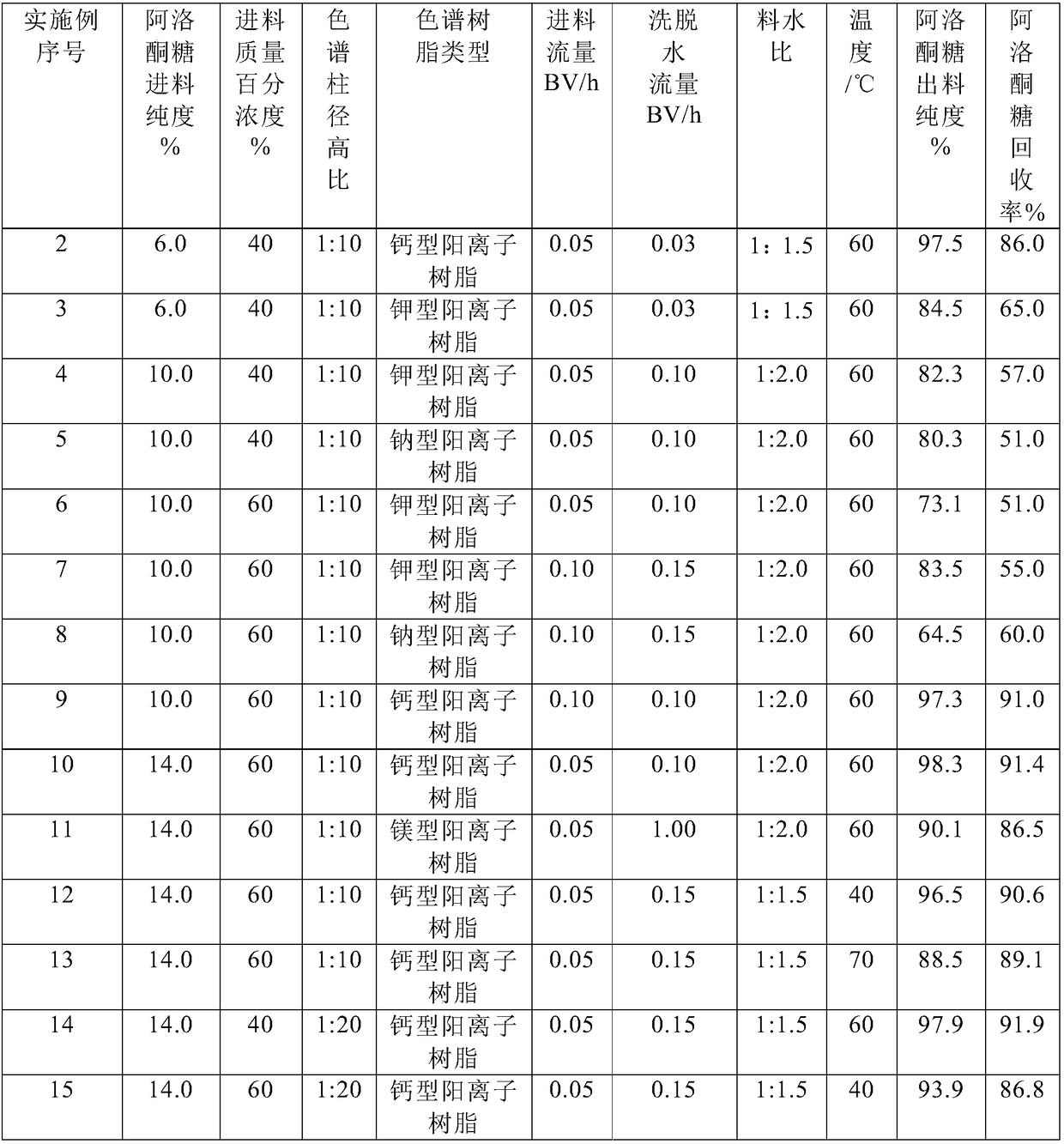

[0127] According to the operation of example 1, feed 1.0Kg, chromatographic column length 100cm, adjust factors such as feed temperature, column temperature, feed speed, elution speed and chromatographic column diameter-height ratio, the results are shown in Table 1, in Table 1 The resin particle size of chromatographic separation is: 50-500um.

[0128] Table 1

[0129]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com