A kind of antibacterial non-woven fabric and its preparation method and application

A technology of non-woven fabrics and aqueous solutions, applied in textiles and papermaking, pharmaceutical formulations, non-woven fabrics, etc., can solve the problems of poor antibacterial effect, improve antibacterial effect, improve skin softness and toughness, and hydrophilic strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

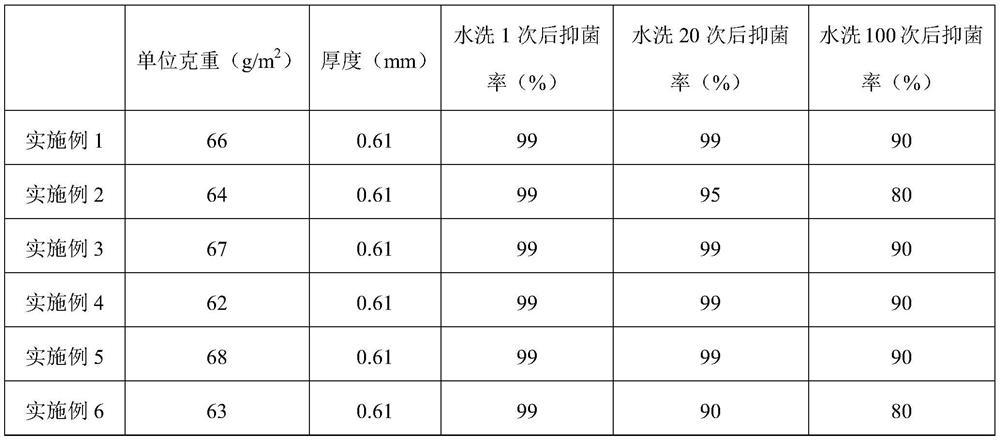

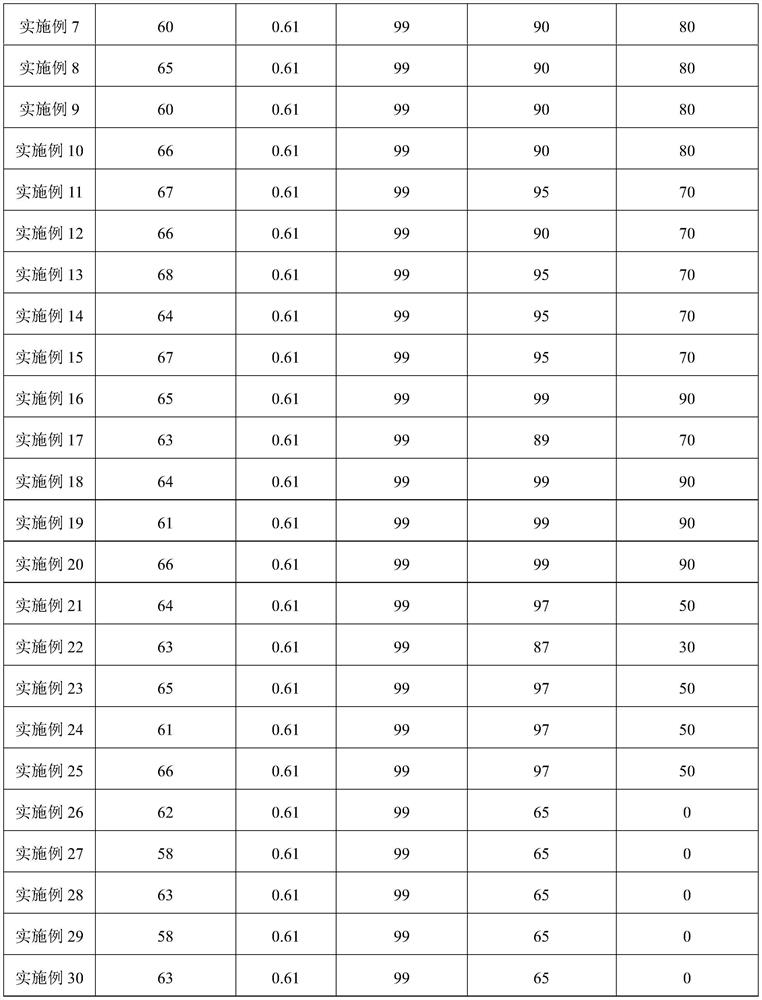

Examples

Embodiment 1

[0036] In this example, a non-woven fabric is prepared by the following method, which includes the following steps:

[0037] A composite fiber composed of viscose fiber and biomass graphene is used as the raw material of the non-woven fabric, and the length of the composite fiber is 38 mm.

[0038] Prepare the antibacterial non-woven fabric through the steps of opening, carding, netting, spunlace, drying, and winding, wherein the spunlace step uses a hydrogen peroxide solution containing biomass graphene to spunlace at room temperature and high pressure, The mass percent concentration of biomass graphene in the hydrogen peroxide solution is 1%, the molar solubility of the hydrogen peroxide solution is 3mmol / mL, and the high pressure is a pressure of 2×10 6 Mpa, the mass percent content of biomass graphene in the composite fiber is 2%.

[0039] figure 1 It is a schematic diagram of the fiber structure of the nonwoven fabric prepared in this example.

Embodiment 2

[0041] In this example, non-woven fabrics were prepared by the following method:

[0042] A composite fiber composed of viscose fiber and biomass graphene is used as the raw material of the non-woven fabric, and the length of the composite fiber is 45mm.

[0043] Prepare the antibacterial non-woven fabric through the steps of opening, carding, netting, spunlace, drying, and winding, wherein the spunlace step uses a hydrogen peroxide solution containing biomass graphene to spunlace at room temperature and high pressure, The mass percent concentration of biomass graphene in the hydrogen peroxide solution is 0.5%, the molar solubility of the hydrogen peroxide solution is 1mmol / mL, and the high pressure is a pressure of 4×10 6 Mpa, the mass percent content of biomass graphene in the composite fiber is 2.5%.

Embodiment 3

[0045] In this example, non-woven fabrics were prepared by the following method:

[0046] A composite fiber composed of viscose fiber and biomass graphene is used as the raw material of the non-woven fabric, and the length of the composite fiber is 51 mm.

[0047] Prepare the antibacterial non-woven fabric through the steps of opening, carding, netting, spunlace, drying, and winding, wherein the spunlace step uses a hydrogen peroxide solution containing biomass graphene to spunlace at room temperature and high pressure, The mass percent concentration of biomass graphene in the hydrogen peroxide solution is 3%, the molar solubility of the hydrogen peroxide solution is 5mmol / mL, and the high pressure is a pressure of 3×10 6 Mpa, the mass percent content of biomass graphene in the composite fiber is 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com