Hazardous waste incineration complete equipment and treatment technology

A technology of hazardous waste and complete sets of equipment, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as insufficient utilization of waste heat, sharp fluctuations in output, and complex properties of hazardous waste materials, so as to improve energy utilization efficiency and reduce Environmental heat pollution, the effect of improving heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

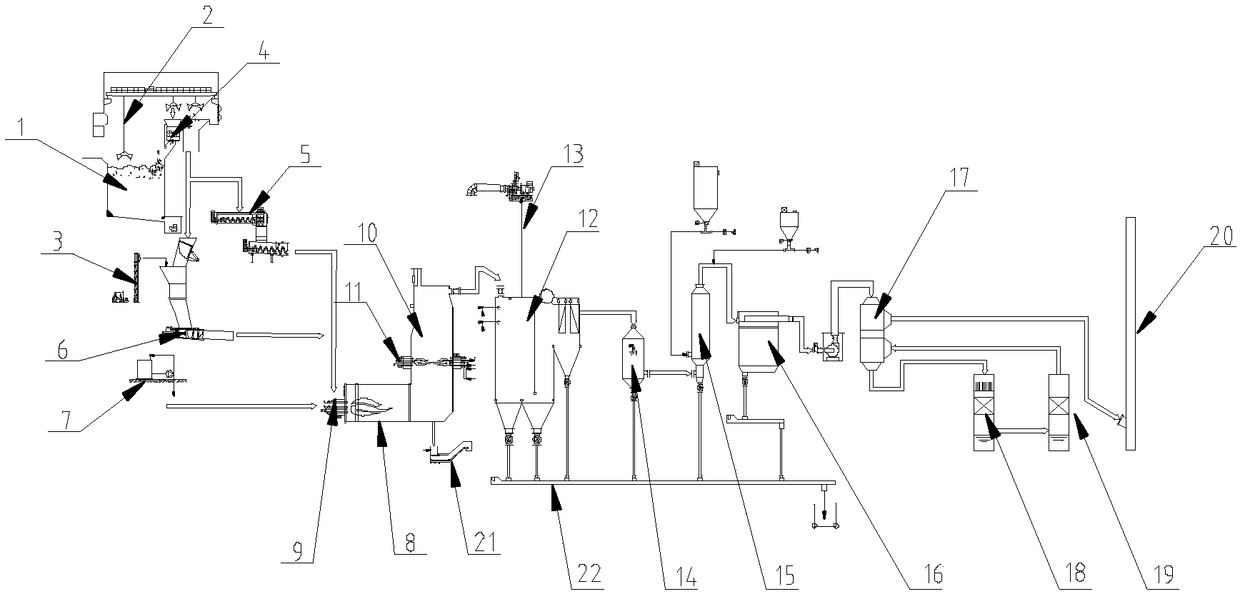

[0028] Such as figure 1 As shown, a complete set of hazardous waste incineration equipment, including pretreatment and feeding system, incineration system, waste heat utilization system, flue gas treatment system and ash collection system.

[0029] Wherein, the pretreatment and feeding system includes a hazardous waste storage area 1, a driving grab crane 2, a hoist 3, a hazardous waste crusher 4, a screw pusher feeder 5, a hydraulic pusher feeder 6 and waste Liquid feeding machine 7, the hazardous waste storage area 1 is used to store classified hazardous waste, the driving grab crane 2 is arranged above the hazardous waste storage area 1, and is used to lift the waste in the hazardous waste storage area 1 Into the screw pusher feeder 5 or the hydraulic pusher feeder 6, the hazardous waste crusher 4 is used to crush large pieces of hazardous waste, preferably, the hazardous waste crusher 4 adopts rotary shear crushing The machine has strong crushing ability and high efficien...

Embodiment 2

[0035] This embodiment provides a treatment process for a complete set of hazardous waste incineration, including the following steps:

[0036] Hazardous wastes are stored in hazardous waste storage area 1 after entering the site inspection and pre-classified. Hazardous waste in hazardous waste storage area 1 is lifted by driving grab crane 2 into screw pusher feeder 5 and unloaded into rotary kiln 8 for incineration. Hazardous waste or hazardous waste in barrels or bags enters the hazardous waste crusher 4 through the driving grab crane 2 or hoist 3 for crushing, and the crushed materials are then lifted by the driving grab crane 2 and enter the screw pusher feeder 5 is unloaded into the rotary kiln 8 for incineration; small-sized barreled and bagged hazardous waste is directly sent to the rotary kiln 8 for incineration through the elevator 3 through the hydraulic pusher feeder 6; liquid hazardous waste is transported into the rotary kiln 8 by the waste liquid feeder 7 incine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com