Preparation method of nitrogen-doped graphene modified carbon felt

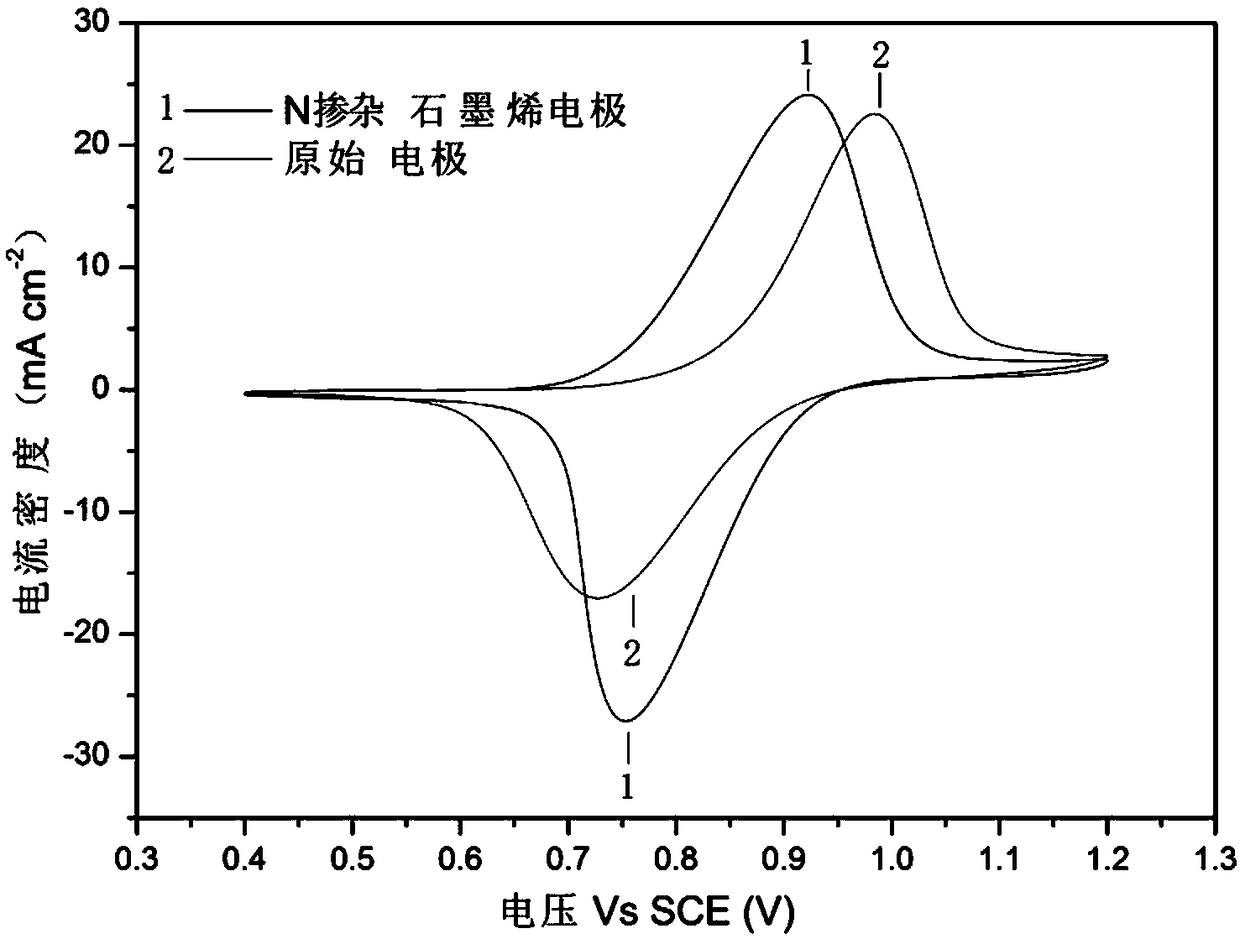

A technology of nitrogen-doped graphene and graphene modification, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of poor electrocatalytic performance of vanadium ions, poor conductivity of carbon felt, and low performance of single cells, and achieve Simple operation, improved conductivity, low polarization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In the present embodiment, the preparation method of nitrogen-doped graphene modified carbon felt comprises the following steps:

[0046] 1. The method for carbon felt processing, comprises the following steps:

[0047] (1) Dry the carbon felt with an area of 5cm×6cm at 400-500°C for 20-30min.

[0048] (2) Soak the dried carbon felt in 2mol / L sulfuric acid aqueous solution for 20h, and then ultrasonically vibrate for 0.5h.

[0049] (3) The soaked carbon felt was repeatedly washed 12 times with deionized water.

[0050] (4) Dry the cleaned carbon felt at 100° C. for 12 hours.

[0051] 2. The preparation method of graphene modified carbon felt, the steps are as follows:

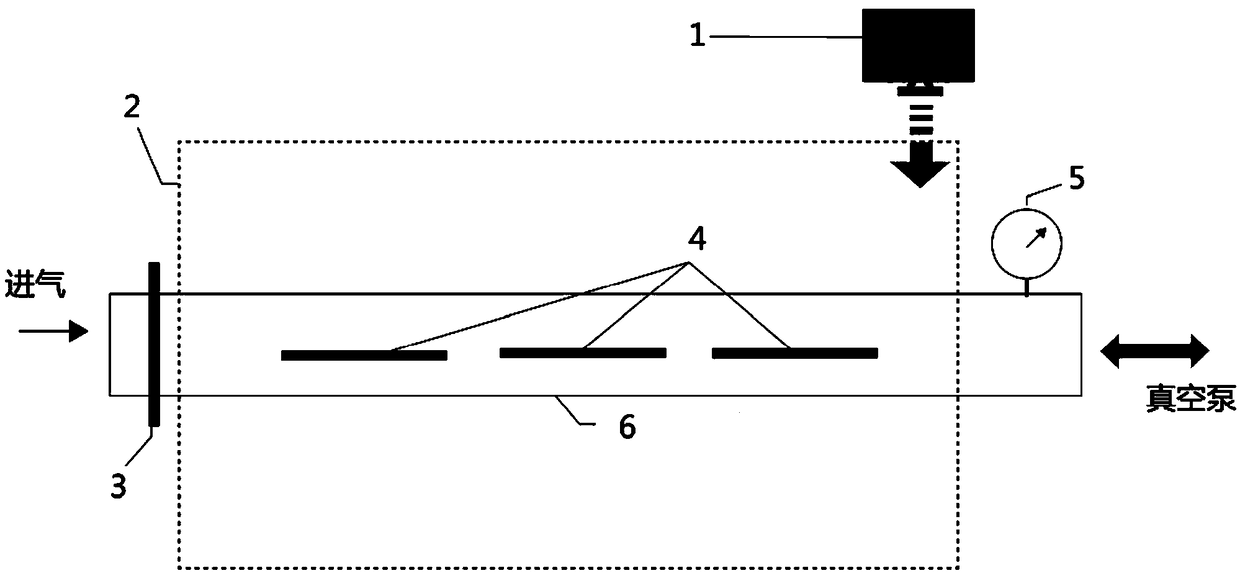

[0052] (1) Put the treated carbon felt into the quartz tube. The carbon felt is placed horizontally and parallel, and the quartz tube is pushed to the central heating area of the heating furnace.

[0053] (2) Seal the quartz tube, close the air valve, and then turn on the vacuum pump to evacuate ...

Embodiment 2

[0068] The difference from Example 1 is:

[0069] 1. The time for preparing graphene-modified carbon felt by chemical vapor deposition in step (9) of step 2 is 5 minutes.

[0070] 2. Adopt all the other same steps of embodiment 1 to prepare graphene-modified carbon felt. In the graphene-modified carbon felt, the nitrogen doping amount is 0.35wt%.

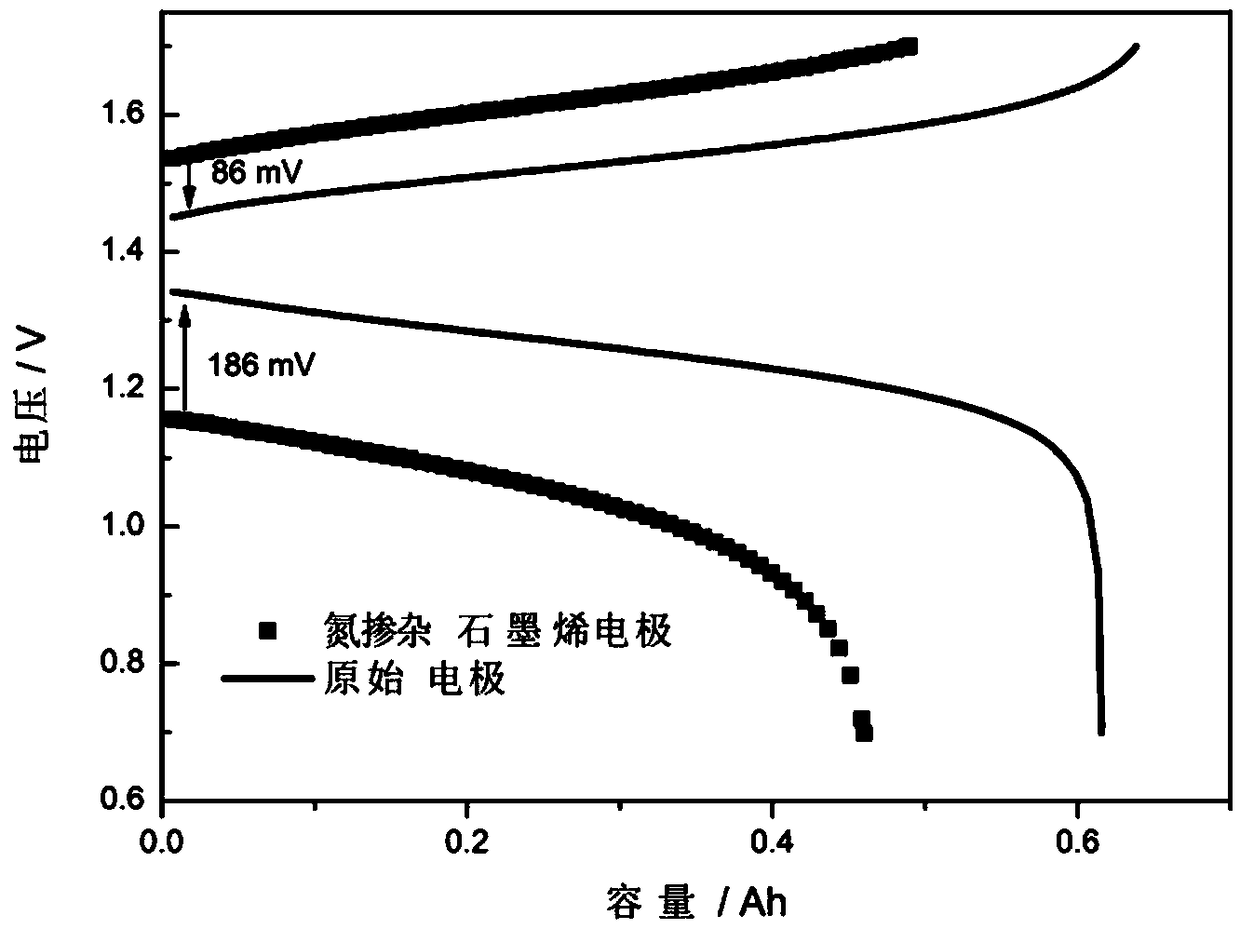

[0071] The conductivity of the nitrogen-doped graphene-modified carbon felt prepared at this ratio was measured at room temperature to be 4.0 S cm -1 , is more than 2 times that of commercial carbon felt, slightly lower than the conductivity of the modified carbon felt in Example 1, and the battery voltage efficiency in VRB is also correspondingly lower. Stability needs to be further improved.

Embodiment 3

[0073] The difference from Example 1 is:

[0074] 1. The time for preparing graphene-modified carbon felt by chemical vapor deposition in step (9) of step 2 is 20 minutes.

[0075] 2. Adopt all the other same steps of embodiment 1 to prepare graphene-modified carbon felt. In the graphene-modified carbon felt, the nitrogen doping amount is 0.9wt%.

[0076] Due to the increase of graphene deposition time, under the same conditions, the loading amount of graphene on the modified electrode increased, so the conductivity of the composite electrode was increased to 5.0 S cm -1 higher than that of Examples 1 and 2. The voltage efficiency of the battery in VRB is higher than that of the original carbon felt, but the composite carbon felt has a long deposition time, and the corresponding cost will be higher than that of Example 1, which can be well adapted to the vanadium battery system, and its low cost and good battery performance can Promote large-scale commercial production of v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com