Slow-release heat supply device for heat battery

A technology of heating device and thermal battery, applied in the direction of delayed action cells, etc., can solve the problems of low utilization rate of positive electrode material and heat dissipation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

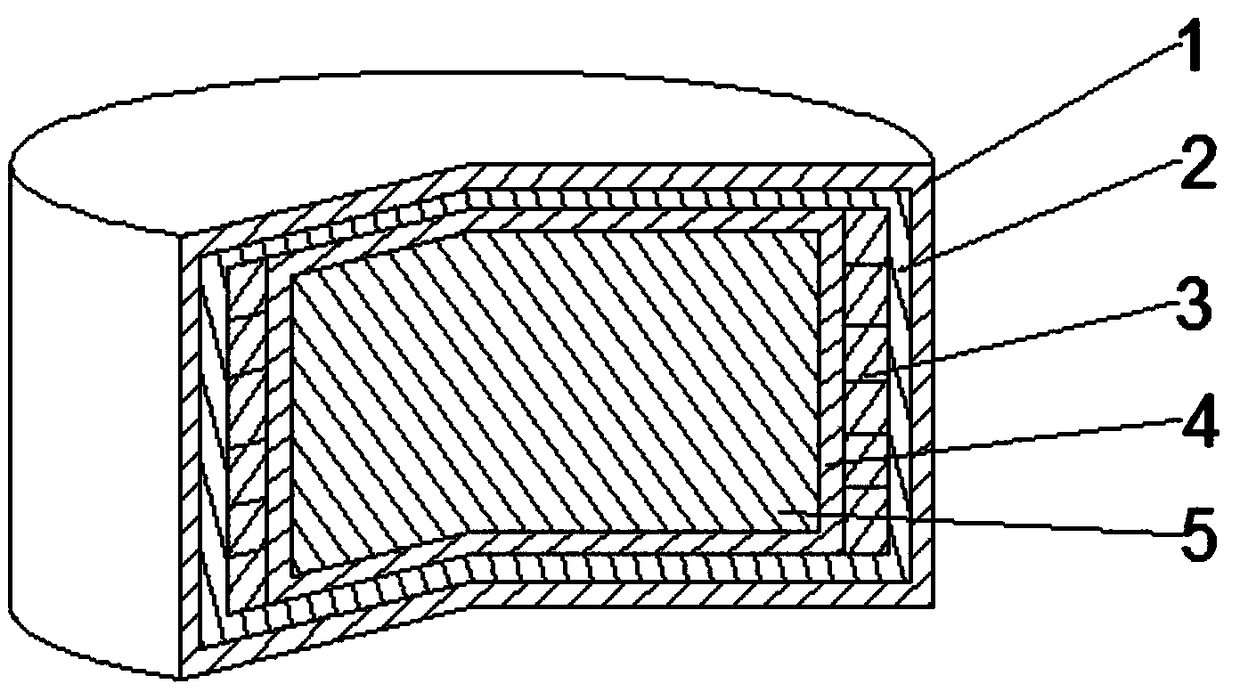

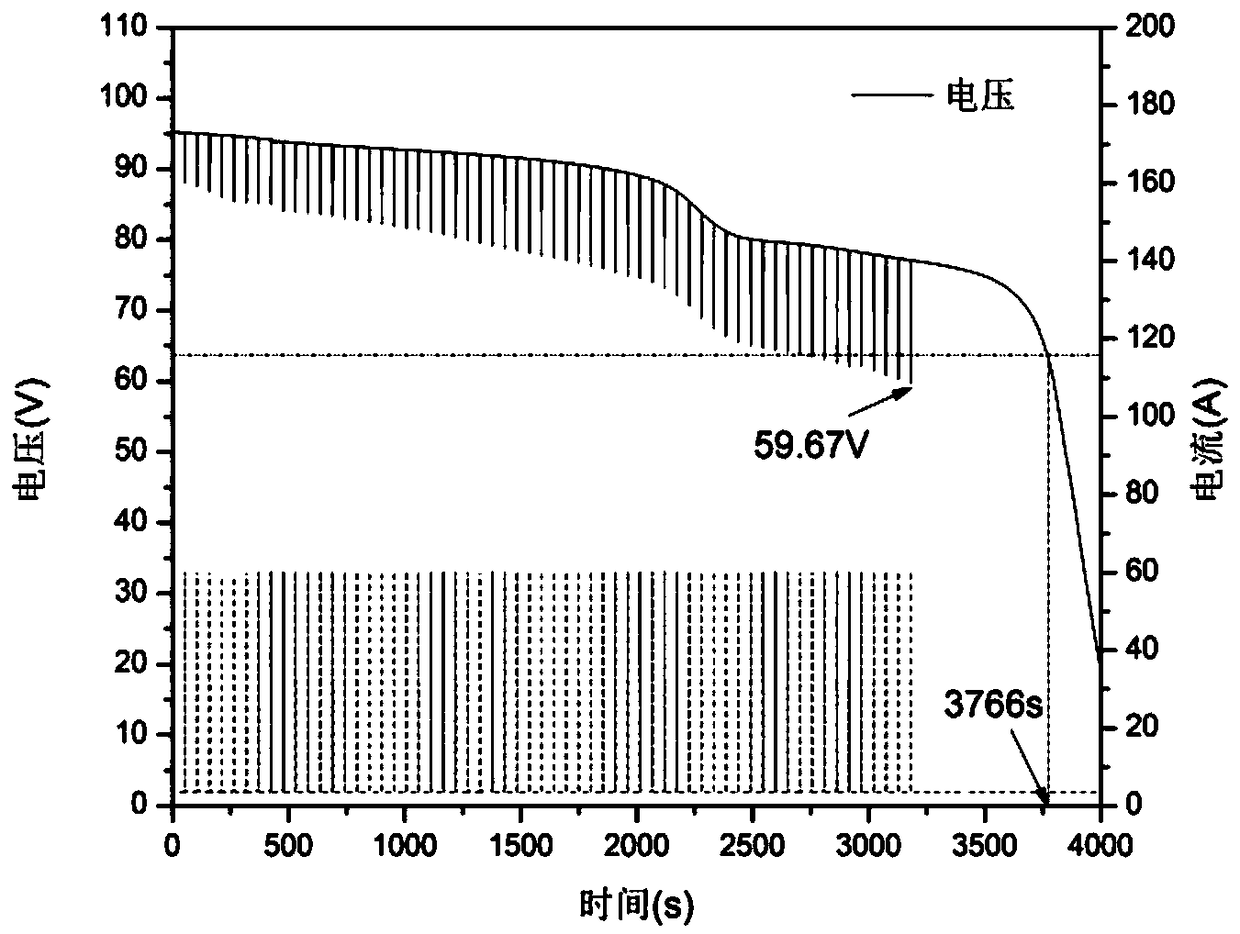

Embodiment 1

[0024] Embodiment 1, the positive electrode material active material is iron disulfide and cobalt disulfide, the mass ratio of the two is 1:1, the heating material is iron powder and potassium perchlorate powder, the mass ratio of the two is 84:16, and the diaphragm material is magnesium oxide and lithium chloride-potassium chloride-lithium bromide eutectic molten salt, the mass ratio of the two is 50:50, the negative electrode material is lithium-boron alloy, the heating material, positive electrode material, and diaphragm material are put into a 74mm diameter mold and paved, Then put lithium-boron alloy sheet, metal current collector, and press molding at one time to form a typical thermal battery single structure, and 47 such single structures are stacked to form the battery stack 5 of the thermal battery. Among them, the mass of the single positive electrode material is 13.5g, the mass of the single diaphragm material is 4.9g, the mass of the single lithium boron alloy is 3...

Embodiment 2

[0025] Embodiment 2, the active material of the positive electrode material is iron disulfide and cobalt disulfide, the mass ratio of the two is 1:1, the heating material is iron powder and potassium perchlorate powder, the mass ratio of the two is 84:16, and the diaphragm material is magnesium oxide and lithium chloride-potassium chloride-lithium bromide eutectic molten salt, the mass ratio of the two is 50:50, the negative electrode material is lithium-boron alloy, the heating material, positive electrode material, and diaphragm material are put into a 74mm diameter mold and paved, Then put lithium-boron alloy sheet, metal current collector, and press molding at one time to form a typical thermal battery single structure, and 47 such single structures are stacked to form the battery stack 5 of the thermal battery. Among them, the mass of the single positive electrode material is 15.5 g, the mass of the single diaphragm material is 5.0 g, the mass of the single lithium boron a...

Embodiment 3

[0026]Embodiment three, the active material of the positive electrode material is cobalt disulfide, the heating material is iron powder and potassium perchlorate powder, the mass ratio of the two is 84:16, and the diaphragm material is magnesium oxide and lithium chloride-potassium chloride-lithium bromide eutectic melting Salt, the mass ratio of the two is 50:50, the negative electrode material is lithium-boron alloy, put the heating material, positive electrode material, and diaphragm material into a 74mm diameter mold and spread it flat, then put lithium-boron alloy sheet, metal current collector, once Press molding to form a typical thermal battery cell structure, and 47 such single structures are stacked to form a battery stack 5 of a thermal battery. Among them, the mass of the single positive electrode material is 19.2g, the mass of the single diaphragm material is 4.8g, the mass of the single lithium boron alloy is 3.0g, and the mass of the single heating material is 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com