A kind of high specific energy zinc-silver battery and preparation method thereof

A zinc-silver battery and energy technology, applied in the manufacturing of silver batteries, alkaline batteries, secondary batteries, etc., can solve the problems of low specific energy of zinc-silver batteries, reduce internal resistance, have obvious effects, and increase the utilization rate of active materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

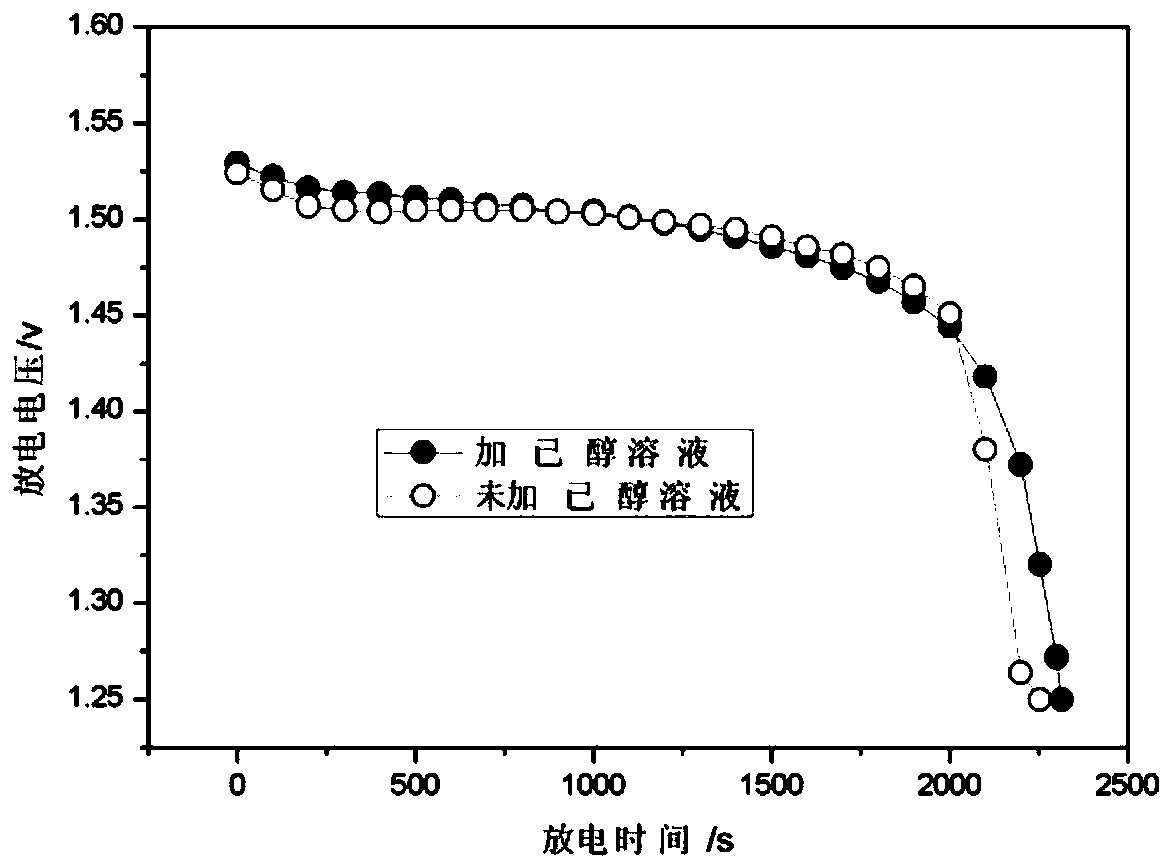

[0017] Example 1, a method for preparing a high specific energy zinc-silver battery. The positive electrode and the negative electrode are prepared by sintered silver electrode technology and paste-coated zinc electrode. The pole group is formed in the form of laminations. The positive end of the pole group is drawn out through the positive current collector silver wire, and the negative end is drawn out through the negative current collector silver wire. When the zinc-silver battery is formed, the electrolyte used is 25% potassium hydroxide aqueous solution by mass percentage, 92% ethanol solution is added during the formation process, and the mass ratio of the ethanol solution to the formed electrolyte is 0.2. After forming and drying, a single zinc-silver battery is formed, the positive electrode is composed of 5 silver plates, and the negative electrode is composed of 5 zinc plates.

[0018] Embodiment 1 discharge curve contrast sees figure 1 , through the 10A current tes...

Embodiment 2

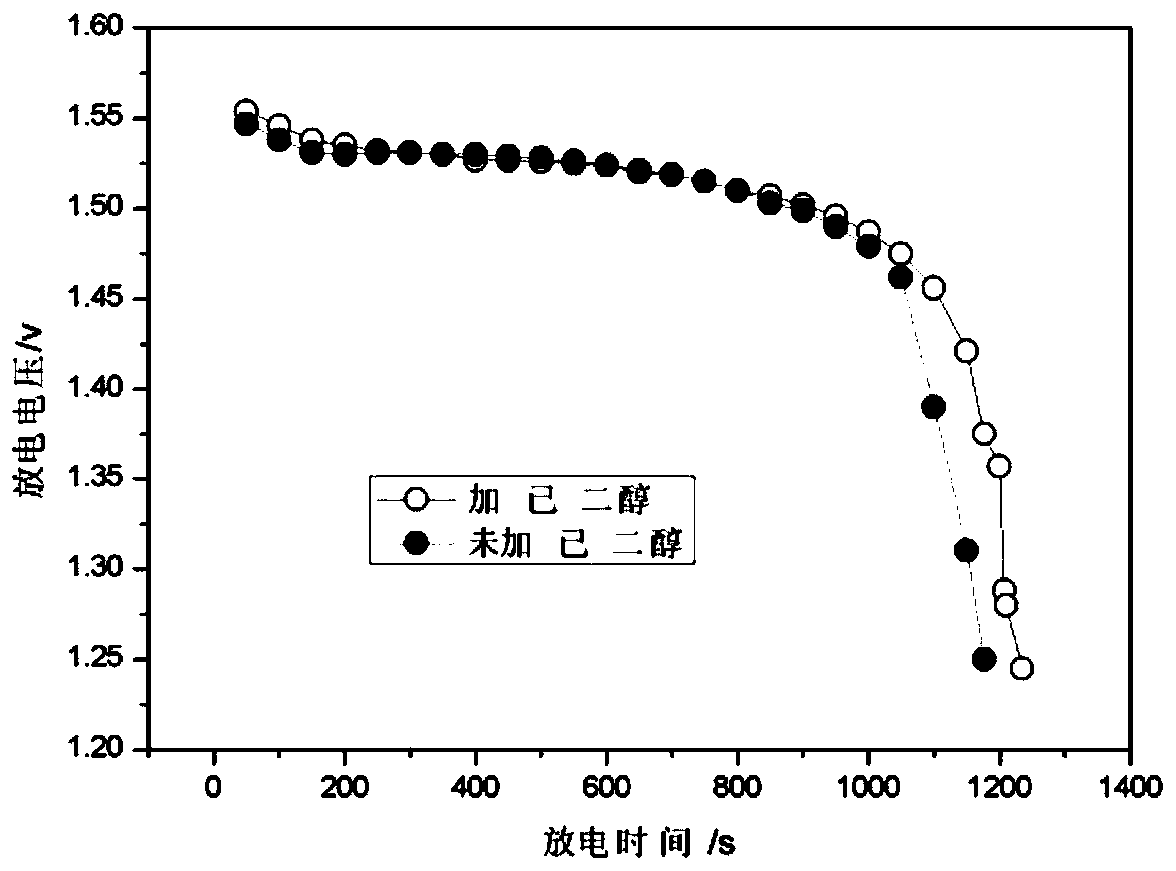

[0019] Example 2, a method for preparing a high specific energy zinc-silver battery. The positive electrode and negative electrode are prepared by sintered silver electrode technology and paste zinc electrode. The pole group is formed in the form of laminations. The positive end of the pole group is drawn out through the positive current collector silver wire, and the negative end is drawn out through the negative current collector silver wire. When the zinc-silver battery is formed, the electrolyte used is 30% potassium hydroxide aqueous solution by mass percentage, 90% ethylene glycol solution is added during the formation process, and the mass ratio of the ethylene glycol solution to the formed electrolyte is 0.1. After forming and drying, a single zinc-silver battery is formed, the positive electrode is composed of 8 silver plates, and the negative electrode is composed of 8 zinc plates.

[0020] Embodiment 2 discharge curve contrast sees figure 2 , through the 30A curre...

Embodiment 3

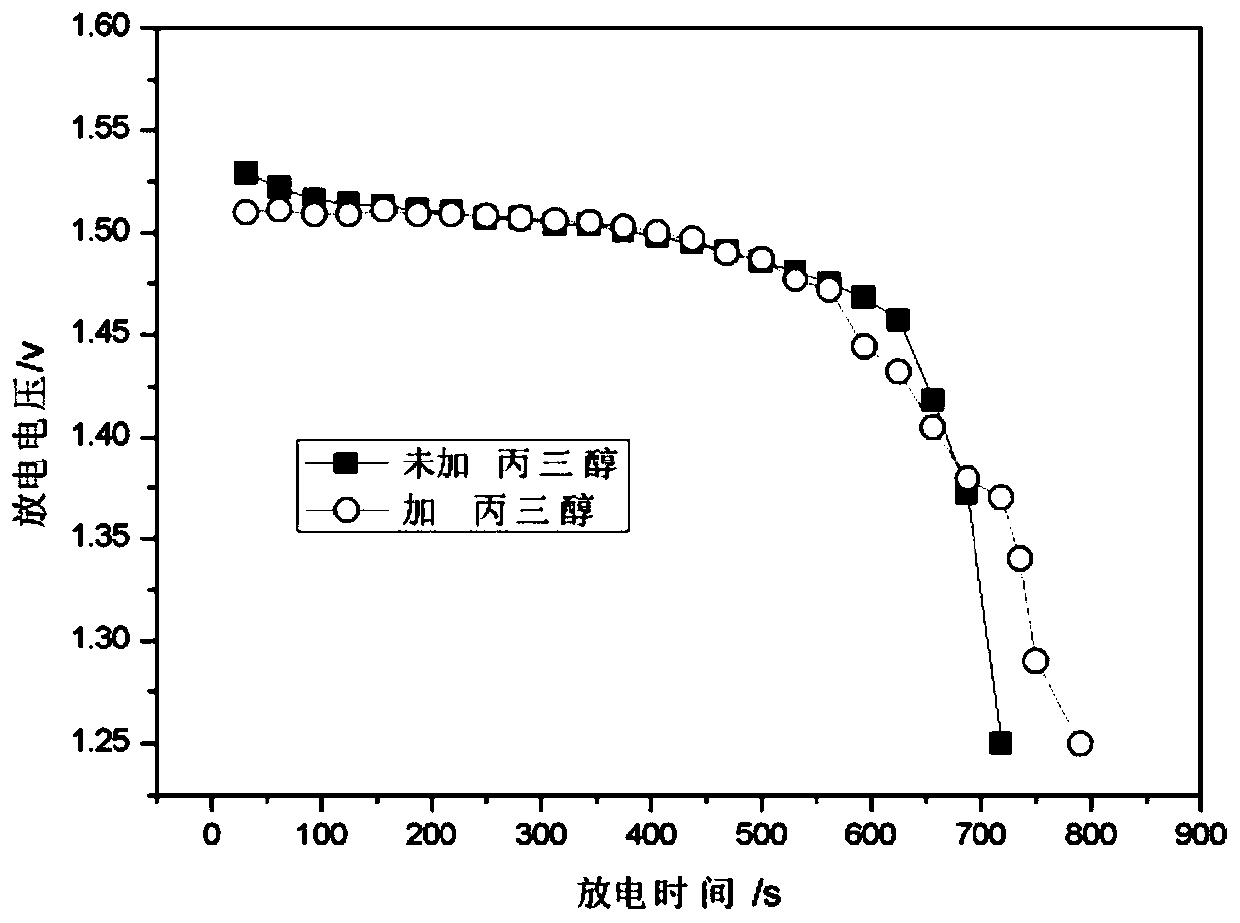

[0021] Example 3, a method for preparing a high specific energy zinc-silver battery. The positive electrode and the negative electrode are prepared by sintering silver electrode technology and pasted zinc electrode. The pole group is formed in the form of laminations. The positive end of the pole group is drawn out through the positive current collector silver wire, and the negative end is drawn out through the negative current collector silver wire. When the zinc-silver battery is formed, the electrolyte used is 45% potassium hydroxide aqueous solution by mass percentage, 90% glycerol solution is added during the formation process, and the mass percentage of the glycerol solution and the formed electrolyte is 0.05. After formation, it is dried to form a single zinc-silver battery. The positive electrode is composed of 3 silver plates, and the negative electrode is composed of 3 zinc plates.

[0022] Embodiment 3 discharge curve comparison see image 3 , through the 5A curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com