A kind of manufacturing method of high specific capacity supercapacitor

A supercapacitor, high specific capacity technology, applied in the field of capacitor manufacturing, can solve the problems of weak charge absorption capacity of energy storage devices, cycle life capacity attenuation of energy storage devices, low specific energy, etc., so as to enhance the charge absorption capacity and improve the cycle life. , the effect of increasing the proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

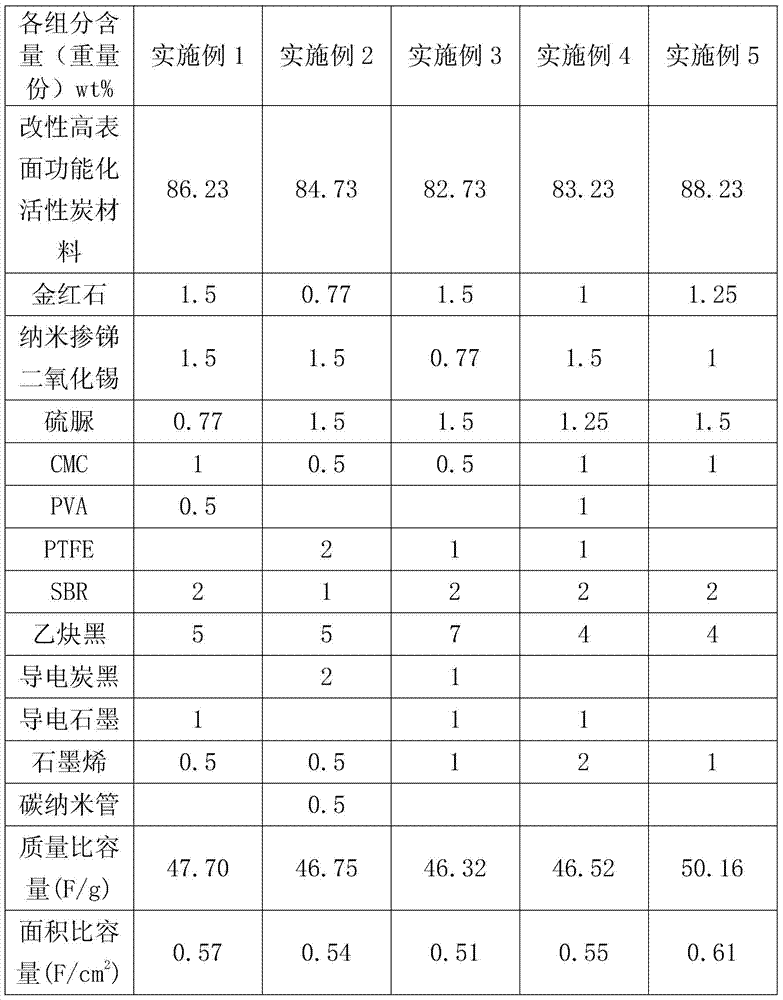

Examples

Embodiment Construction

[0029] The manufacture method of high specific capacity supercapacitor of the present invention, comprises the following steps:

[0030] S010, preparation of CMC solution

[0031] Add 98.5kg of deionized water into a 150L vacuum stirring tank, weigh 1.5kg of battery-grade CMC, add it to the vacuum stirring tank in three times, add 0.5kg each time, and the interval between each feeding is 15-20min, and the ambient temperature is 25±2 °C; after the addition, stir in vacuum for 2-4 hours until the CMC is completely dissolved, and store in vacuum;

[0032] S020. Preparation of conductive paste

[0033] Take by weighing 67.5kg of the above-mentioned CMC solution in a 100L vacuum stirring tank, 15kg of conductive agent acetylene black, 10kg of conductive graphite, 25kg of graphene slurry, and 5kg of accelerator (wherein rutile type TiO 2 2.5kg, nano antimony-doped tin dioxide 1.5kg, thiourea 1kg) were sequentially added into the vacuum stirring tank, wherein acetylene black was ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size distribution | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com