Coatings

A coating and coating technology, used in the field of removing polluting gases, can solve problems such as weight loss, and achieve the effect of small impact on integrity and appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

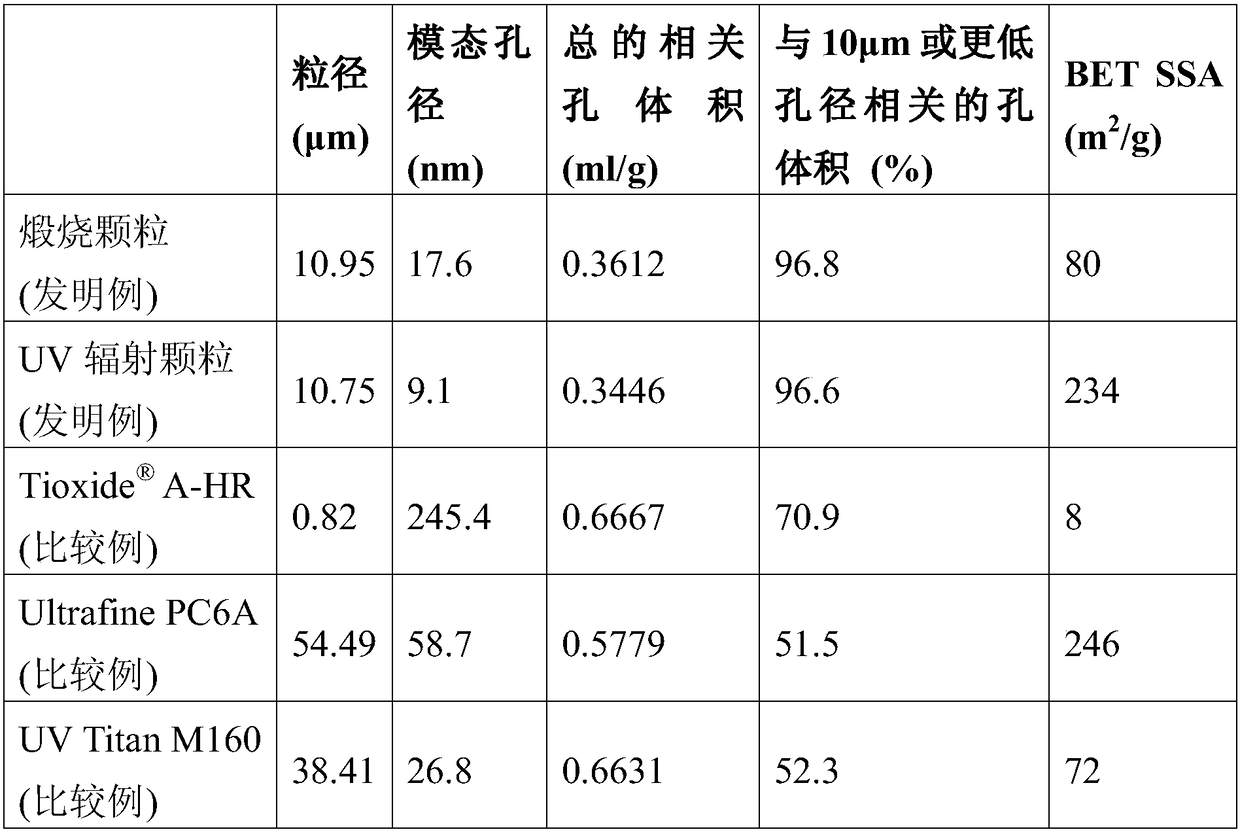

[0142] Example 1 - Preparation of Mesoporous Titanium Dioxide Particles

[0143] Mesoporous titanium dioxide particles were obtained according to the method described in WO2015 / 040426.

[0144]In this case, the slurry from the sulfate process is neutralized and washed to remove sulfate. HCl was added to peptize the slurry and citric acid was added to change the isoelectric point. Monoisopropanolamine was then added to raise the pH to about 7, at which point a clear sol was observed to have formed. The clear neutral sols are spray dried under controlled conditions. Specifically, the concentrated sol was fed into a spray dryer using a Lab Plant Super 7 laboratory spray dryer under the condition of a solid content of 17 wt% at 110° C. to prepare mesoporous titania particles.

[0145] Mesoporous titania particles were treated to remove citric acid. The treatment consists of one of two methods: (a) calcination at a temperature of 500°C for 8 hours or (b) with an intensity of 10...

Embodiment 2

[0161] Example 2 - Preparation of coatings containing mesoporous titanium dioxide particles

[0162] Paint bases were prepared according to Appendix 1 and then used with the particles as listed in Table 1 above.

[0163] For the "blank" paint (Sample 1), no pigment was added.

[0164] For sample 2, no pigment was added in forming the paint base, but the conventional pigment anatase titanium dioxide (available from Huntsman P&A UK Ltd) was provided as a layer on the paint base in the manner described below A-HR pigment).

[0165] For Sample 3, no pigment was added in forming the paint base, but conventional ultrafine anatase titanium dioxide (PC6A from Huntsman P&A UK Ltd) was provided as a layer on the paint base in the manner described below.

[0166] For sample 4, UV irradiated mesoporous titanium dioxide as obtained in Example 1, variant (b) was added as pigment.

[0167] For sample 5, no pigment was added when forming the paint base, but the UV-irradiated mesoporous ti...

Embodiment 3

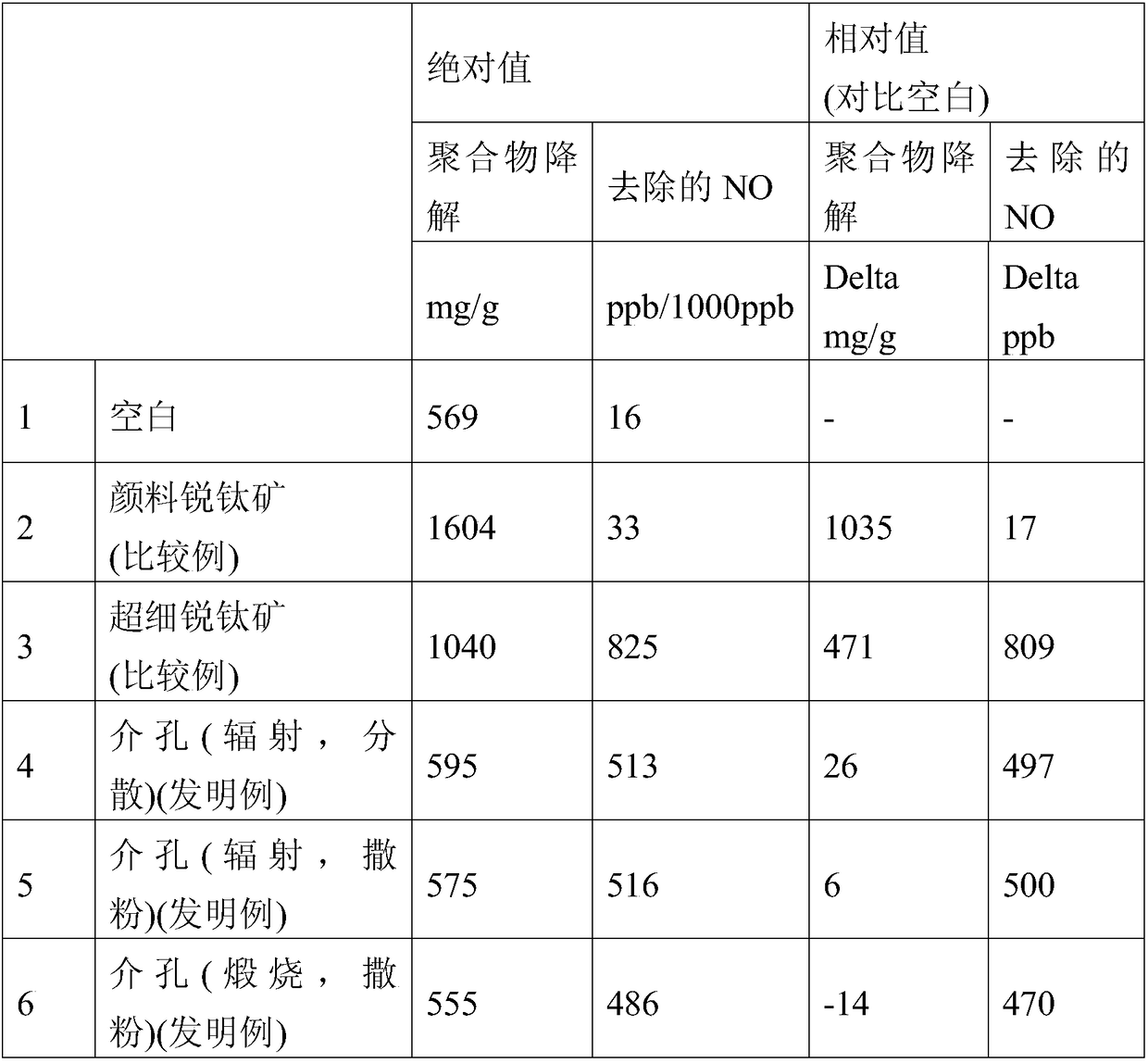

[0172] Example 3 - Ability to remove NO gas

[0173] The coated metal panels prepared in Example 2 were weighed and then weathered in a xenon arc weathering chamber for 1000 hours.

[0174] At 1000 hours, the weight loss was measured and the panels were tested according to ISO22197-1 at a flow rate of 1.5 liters / minute to assess their ability to remove NO gas from a 1000 ppb NO gas stream.

[0175] The results are shown in Table 2 below.

[0176] Table 2

[0177]

[0178] The samples according to the invention (samples 4, 5 and 6) resulted in significantly lower coating weight loss after the same exposure than the samples using conventional (non-mesoporous) titanium dioxide (samples 2 and 3). The weight loss of these samples was similar to the blank sample (Sample 1: resin only).

[0179] From this it can be seen that, surprisingly, the products (samples 4, 5 and 6) comprising mesoporous titanium dioxide according to the invention, i.e. high specific surface area anatase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com