Application of a Surface Modified Sludge Carbon Catalyst

A technology of surface modification and sludge charcoal, which is applied in the direction of physical/chemical process catalysts, non-central analgesics, anti-inflammatory agents, etc., can solve the problems that have not been reported in the relevant literature, and achieve good yield and mild reaction conditions , easy preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

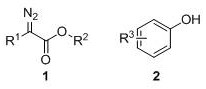

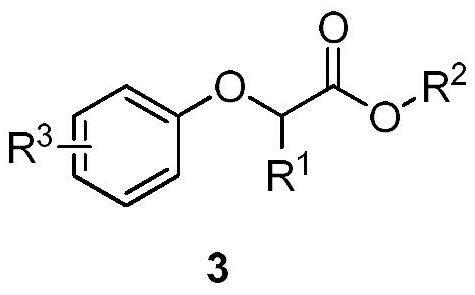

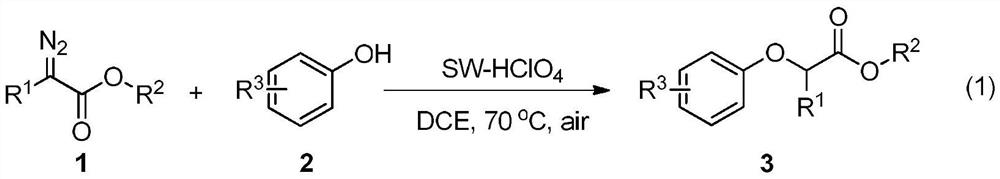

Method used

Image

Examples

preparation example Construction

[0032] Catalyst preparation: Sludge from a sewage treatment plant in Dalian, China, was dried in a muffle furnace at 105 °C to constant weight, and heated to 600°C, continue carbonization for 4 hours, and when the temperature in the furnace drops to room temperature, the carbonaceous material (SW) derived from sewage sludge can be obtained. In order to change the surface activity of SW, different acids were used to treat SW. During acid treatment, by mixing carbonized SW with the same volume of HCl (20.5 wt%), HClO 4 (35.4wt%), H 2 SO 4 (63.4wt%) and HNO 3 (40.5wt%) were impregnated for 24 hours to prepare 50 mL of different acid-treated SWs. Then, wash SW-HCl and SW-HClO with deionized water, respectively 4 、SW-H 2 SO 4 and SW-HNO 3 Until the pH of the washing liquid reaches 6-7, the solid is recovered and dried at room temperature to obtain the corresponding acid-treated surface-modified sludge carbon catalyst SW-HCl, SW-HClO 4 、SW-H 2 SO 4 and SW-HNO 3 . Note: ...

Embodiment 1

[0036] Embodiment 1 (catalyst in the following examples refers to the preparation of catalyst in claim 3)

[0037]

[0038] At room temperature, weigh ethyl phenyldiazoacetate 1a (0.5mmol), p-bromophenol 2a (0.70mmol), SW-HClO 4 (50mg) into a dry and clean 25mL Schlenk reaction tube, under air atmosphere, add 5mL of 1,2-dichloroethane, stir at room temperature for 2-5 minutes, and transfer to an oil bath magnetic stirring heater at 70°C Reacted for 24 hours, TLC detected that the raw material had reacted completely, stopped the reaction, the reaction solution was cooled to room temperature, suction filtered, the filter cake was washed with dichloromethane until the filtrate was colorless, concentrated under reduced pressure to remove volatile components, and separated by silica gel column chromatography ( Eluent: petroleum ether (60-90°C) / ethyl acetate, v / v=10:1), the target product 3a (104mg, yield 62%) was obtained as colorless, transparent and viscous, and the target pro...

Embodiment 2

[0039] Embodiment 2 (comparative example: different catalyst contrasts)

[0040]

[0041] At room temperature, successively weigh ethyl phenyldiazoacetate 1a (0.5mmol), p-bromophenol 2a (0.70mmol), SW-HCl (50mg) in a dry and clean 25mL Schlenk reaction tube, under air atmosphere , add 5 mL of 1,2-dichloroethane, stir at room temperature for 2-5 minutes, transfer to an oil bath magnetic stirring heater at 70°C and react for 24 hours, TLC detects that the raw materials have reacted completely, stop the reaction, and remove the reaction solution Cool to room temperature, filter with suction, wash the filter cake with dichloromethane until the filtrate is colorless, concentrate under reduced pressure to remove volatile components, and separate by silica gel column chromatography (eluent: petroleum ether (60-90°C) / ethyl acetate, v / v=10:1), the target product 3a (35 mg, yield 21%) was obtained as a colorless, transparent and viscous product, which was confirmed by NMR and GC-MS c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com