A microbial treatment agent for degrading aflatoxin b1 and its preparation method and application

A technology of microbial treatment and aflatoxin, applied in the field of animal breeding, can solve the problems of incomplete detoxification, destruction of nutrition, and high cost, and achieve the effects of inhibiting the production of toxins, low cost, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

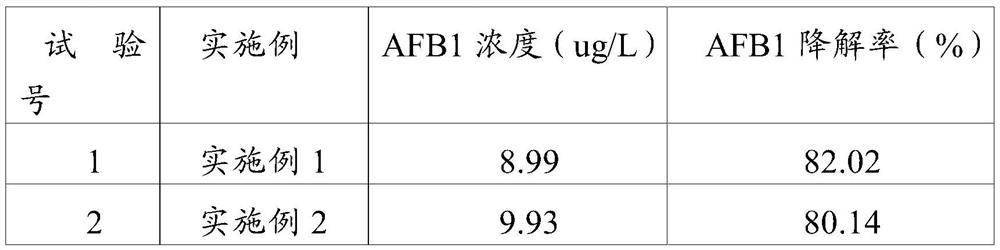

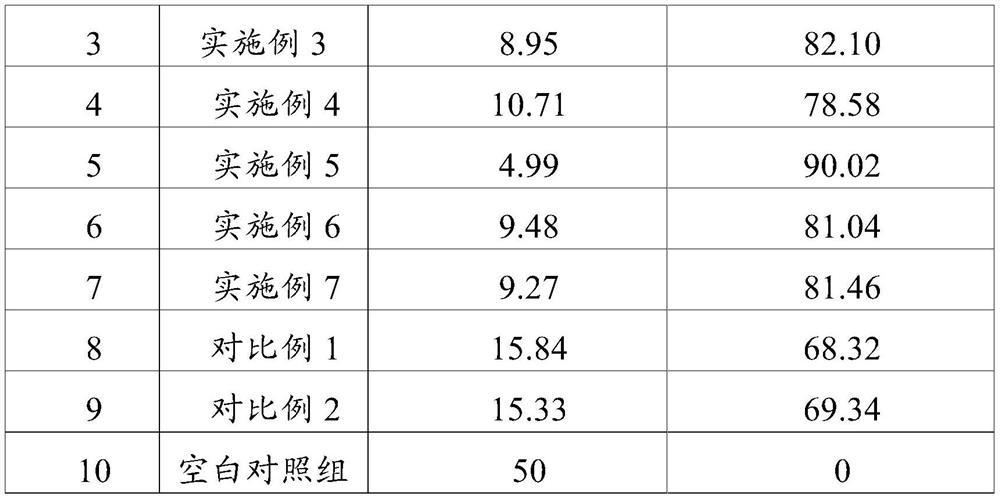

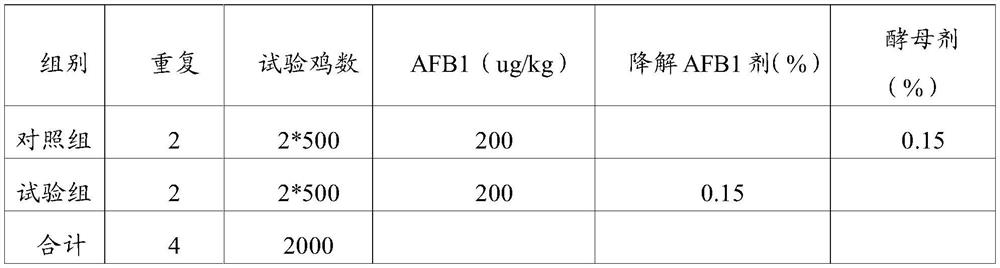

Examples

preparation example Construction

[0039] The invention also discloses a preparation method of a microbial treatment agent for degrading aflatoxin B1, comprising the following steps:

[0040] Step 1. Preparation of probiotic complex:

[0041] Step 1.1, preparation of Saccharomyces cerevisiae culture solution: Inoculate Saccharomyces cerevisiae in Saccharomyces cerevisiae fermentation medium at an inoculum size of 4%-8% (V / V), at 25-30°C, 155-165r / min shaker culture, Harvest when cultured for 27 hours, the content of regulator bacteria is 1×10 9 CFU / ml;

[0042] Among them, the composition of Saccharomyces cerevisiae fermentation medium: glucose 20g, yeast powder 10g, potassium dihydrogen phosphate 1.5g, magnesium sulfate 1g, distilled water 1.0L, natural pH;

[0043] Step 1.2, the preparation of Acetobacter pasteurian culture fluid: inoculate Acetobacter pasteurii in the acetic acid bacteria fermentation medium by the inoculum size of 4%-8% (V / V), at 25-35 ℃, 95-105r / min Cultivate on a shaking table, harvest...

Embodiment 1

[0066] A preparation method of a microbial treatment agent for degrading aflatoxin B1, comprising the following steps:

[0067] Step 1. Preparation of probiotic complex:

[0068] Step 1.1, preparation of Saccharomyces cerevisiae culture medium: Inoculate Saccharomyces cerevisiae in the Saccharomyces cerevisiae fermentation medium at an inoculum size of 6% (V / V), culture at 29°C, 160r / min shaker, harvest when cultured for 27h, adjust The content of bacteria is 1×10 9 CFU / ml;

[0069] Among them, the composition of Saccharomyces cerevisiae fermentation medium: glucose 20g, yeast powder 10g, potassium dihydrogen phosphate 1.5g, magnesium sulfate 1g, distilled water 1.0L, natural pH;

[0070] Step 1.2, preparation of Acetobacter pasteurian culture fluid: inoculate Acetobacter pasteurianum in the acetic acid bacteria fermentation medium by the inoculum size of 6% (V / V), at 30 ℃, 100r / min shaker culture, to be cultivated for 36h When harvested, the content of regulator bacteria w...

Embodiment 2

[0084] A preparation method of a microbial treatment agent for degrading aflatoxin B1, comprising the following steps:

[0085] Step 1. Preparation of probiotic complex:

[0086] Step 1.1, preparation of Saccharomyces cerevisiae culture medium: Inoculate Saccharomyces cerevisiae in the Saccharomyces cerevisiae fermentation medium at an inoculum size of 4% (V / V), culture on a shaker at 30°C and 155r / min, harvest after 27 hours of cultivation, and adjust The content of bacteria is 1×10 9 CFU / ml;

[0087] Among them, the composition of Saccharomyces cerevisiae fermentation medium: glucose 20g, yeast powder 10g, potassium dihydrogen phosphate 1.5g, magnesium sulfate 1g, distilled water 1.0L, natural pH;

[0088] Step 1.2, preparation of Acetobacter pasteurian culture fluid: Inoculate Acetobacter pasteurianus in the acetic acid bacteria fermentation medium by the inoculum size of 4% (V / V), at 35 DEG C, 95r / min shaker culture, to be cultivated for 36h When harvested, the content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com