A three-dimensional porous mos 2 /rgo nanomaterials and their preparation methods and applications

A nanomaterial, three-dimensional porous technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of affecting electronic/ionic conductivity, reducing electrochemical performance, reducing rate performance and cycle stability. To avoid problems such as stability, the reaction is easy to control, the repeatability is high, and the yield is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

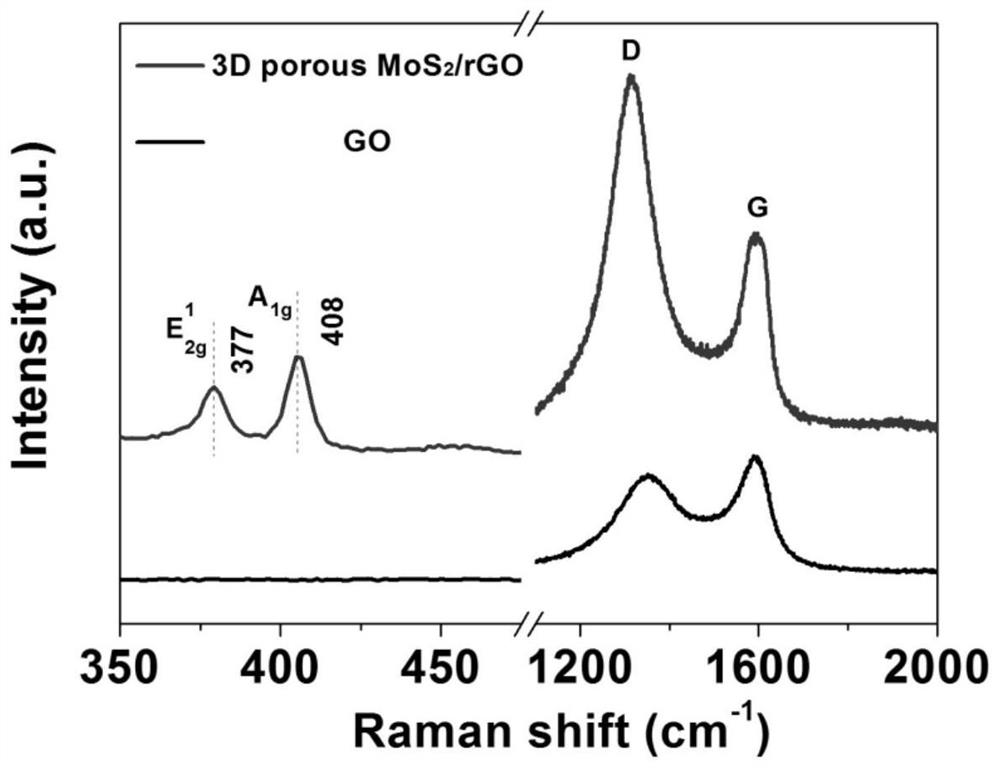

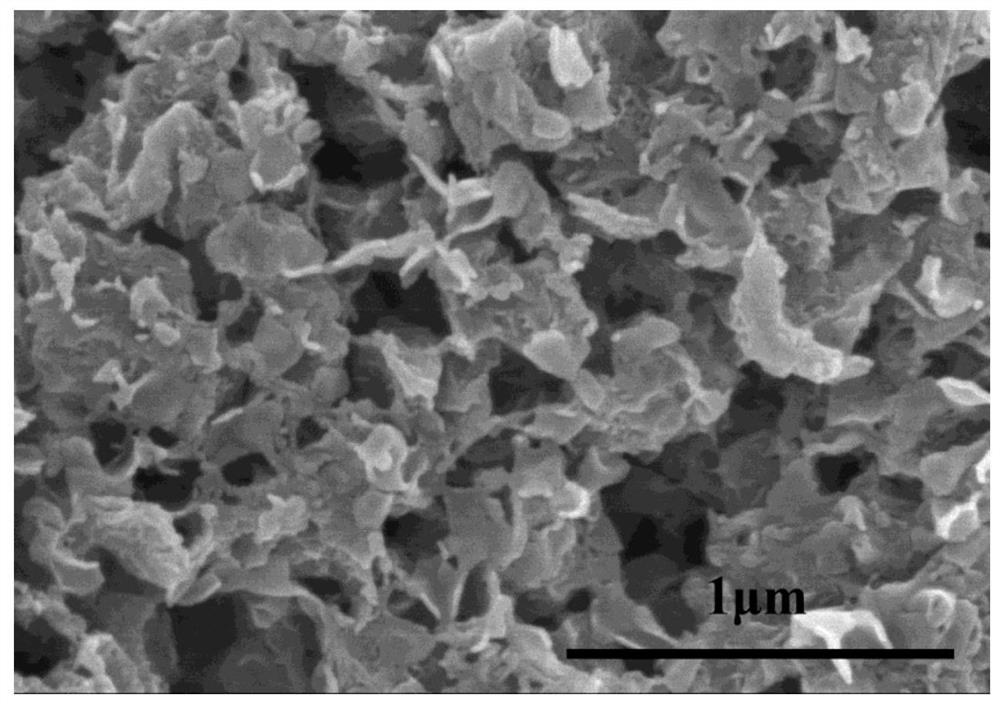

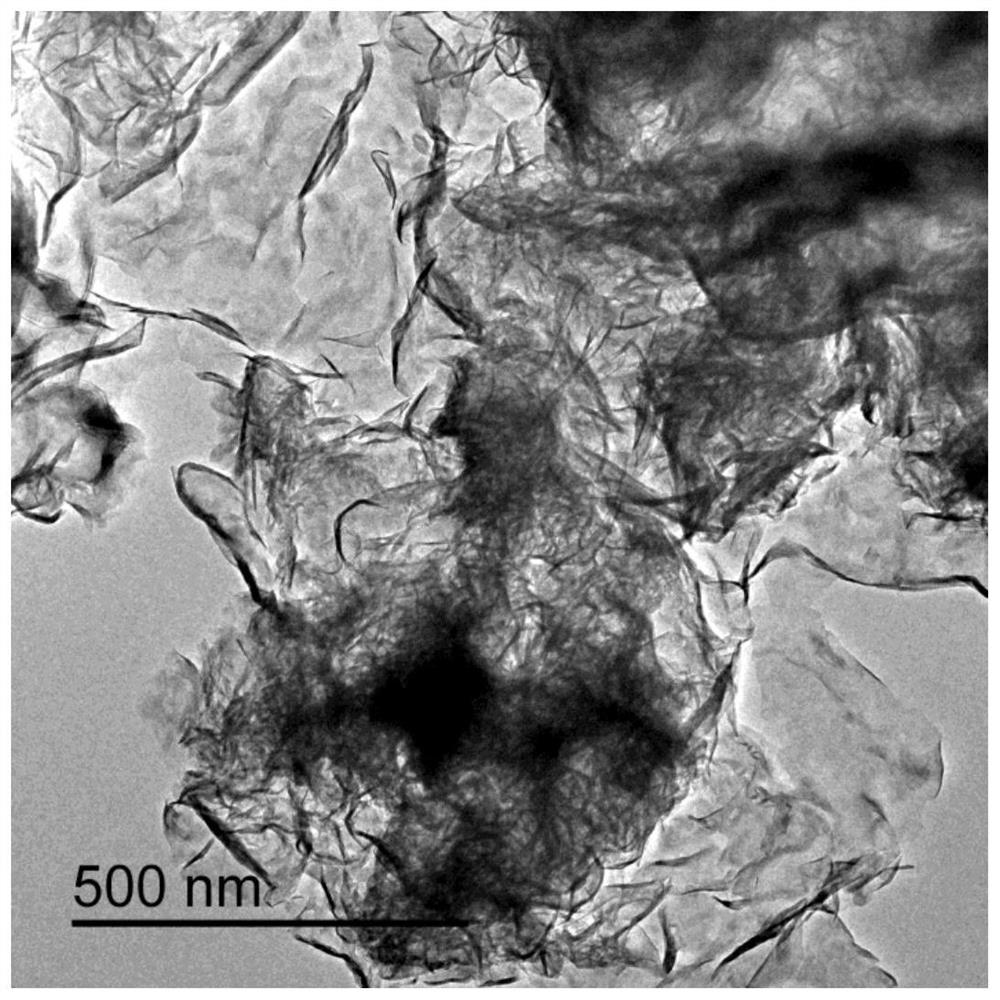

[0028] A three-dimensional porous MoS 2 The preparation method of / rGO nanometer material comprises the following steps:

[0029] 1) Disperse 0.04g GO in about 50mL deionized water, and 1.0g H 2 CNSNH 2 Added to GO / H 2 O dispersion and stirred on a magnetic stirrer for 2h to prepare solution A;

[0030] 2) Add 0.25g MoO 3 Added to the above solution A, stirred by magnetic force and heated to evaporate the water in the solution to obtain the required preform;

[0031] 3) Under the condition of argon as the protective gas, the preform was heated at 5°C for min -1 The rate is heated from room temperature to 600°C and kept for 4.0h;

[0032] During the heat preservation process, when the temperature rises from room temperature to 100°C, the volume flow rate of argon gas is controlled to 0 sccm to maintain a high concentration of S and MoO 3 Reaction, the argon gas is adjusted to 100 sccm after the reaction is finished, to discharge excess gas, then naturally cool to room tem...

Embodiment 2

[0035] A three-dimensional porous MoS 2 The preparation method of / rGO nanometer material comprises the following steps:

[0036] 1) Disperse 0.06g GO in about 50mL deionized water, and 1.5g H 2 CNSNH 2 Added to GO / H 2 O dispersion and stirred on a magnetic stirrer for 3h to prepare solution A;

[0037] 2) Add 0.3g MoO 3 Added to the above solution A, stirred by magnetic force and heated to evaporate the water in the solution to obtain the required preform;

[0038] 3) Under the condition of argon as the protective gas, the preform was heated at 6°C min -1 Heating rate to 650°C, holding temperature for 3.5h;

[0039] During the heat preservation process, when the temperature rises from room temperature to 150 °C, the volume flow rate of argon gas is controlled to 10 sccm to maintain a high concentration of S and MoO 3 Reaction, the argon gas is adjusted to 120 sccm after the reaction is finished, to discharge excess gas, then naturally cool to room temperature;

[0040]...

Embodiment 3

[0042] A three-dimensional porous MoS 2 The preparation method of / rGO nanometer material comprises the following steps:

[0043] 1) Disperse 0.08 g of GO in about 50 mL of deionized water. 2.0g H 2 CNSNH 2 Added to GO / H 2 O dispersion and stirred on a magnetic stirrer for 4h to prepare solution A;

[0044] 2) Add 0.4g MoO 3Added to the above solution A, stirred by magnetic force and heated to evaporate the water in the solution to obtain the required preform;

[0045] 3) Under the condition of argon as the protective gas, the preform was heated at 7°C min -1 Heating rate to 700°C, holding temperature for 3.0h.

[0046] During the heat preservation process, when the temperature rises from room temperature to 200 ° C, the volume flow rate of argon gas is controlled to 0 sccm to maintain high concentrations of S and MoO 3 Reaction, the argon gas is adjusted to 150 sccm after the reaction is finished, to discharge excess gas, then naturally cool to room temperature;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com