Composite coating having antibacterial performance and biocompatibility as well as preparation method and application of composite coating

A biocompatible and composite coating technology, which is applied in the field of composite coatings with both antibacterial and biocompatibility and its preparation, can solve the antibacterial effect of toxic and side effects, short service life of cells, limited application range, etc. problem, to achieve the effects of promoting cell proliferation and differentiation, reducing the decline in antibacterial performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

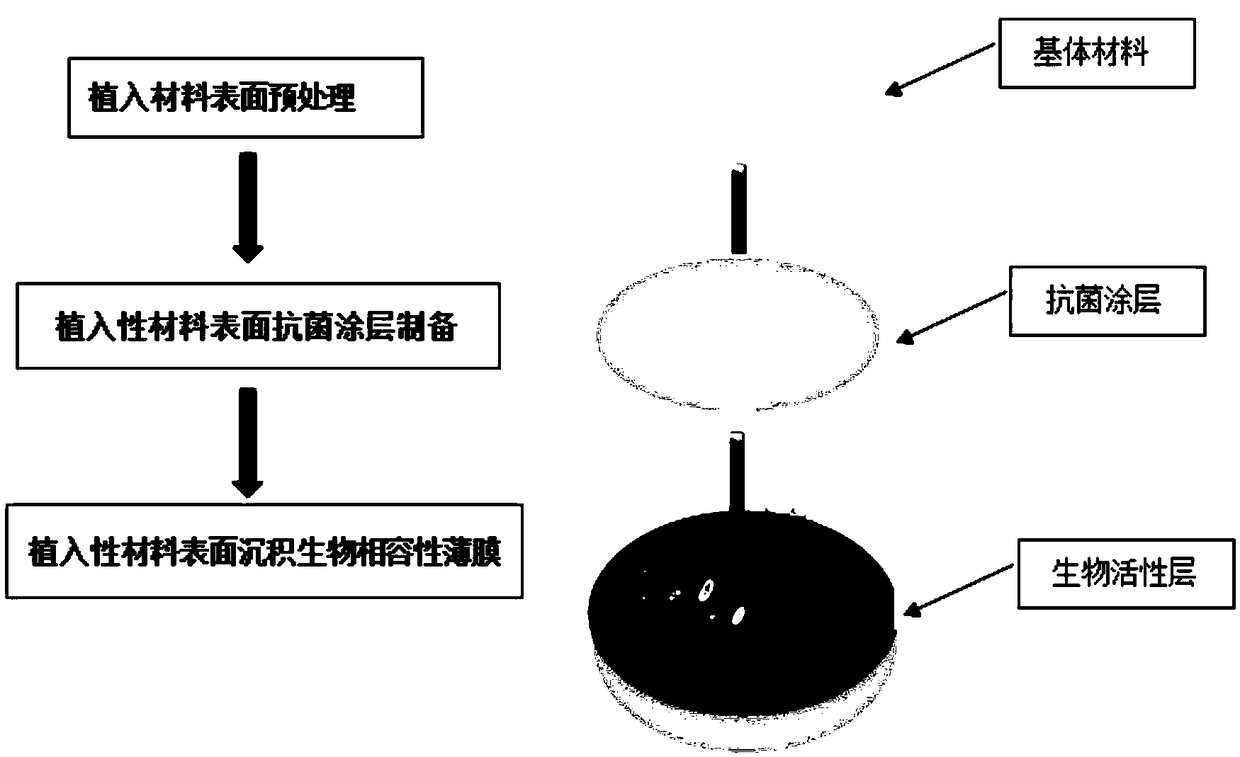

[0066] A composite coating with both antibacterial and biocompatibility, the flow chart of its preparation method is as follows figure 1 As shown, the details are as follows:

[0067] (1) Use the polished titanium as the substrate, ultrasonically in deionized water, ethanol and acetone respectively for 30 minutes, and then use a nitrogen gun to clean the surface;

[0068] (2) Fix the cleaned titanium sheet on the evaporation plate, adopt the electron beam evaporation method, the vacuum degree is 670Pa, the coating rate is 0.16nm / min, TaCu 5 The alloy is used as a target material, and a 40nm TaCu layer is vapor-deposited on the titanium surface obtained in step (1);

[0069] (3) A 5nm Ta layer is vapor-deposited on the surface of the vapor-deposited layer in step (2), and the substrate surface obtains an antibacterial coating with good biocompatibility, and the anti-escherichia coli effect is shown in Figure 2A and Figure 2B .

Embodiment 2

[0071] A composite coating with both antibacterial and biocompatibility, the preparation method of which is as follows:

[0072] (1) The polished titanium alloy Ti-6Al-4V was used as the substrate, and the surface was ultrasonically cleaned in deionized water, ethanol, and acetone for 30 minutes, and then the surface was cleaned with a nitrogen gun;

[0073](2) Fix the cleaned titanium sheet on the evaporation plate, adopt the electron beam evaporation method, the vacuum degree is 465Pa, the coating rate is 0.2nm / min, TaCu 5 The alloy is used as a target material, and a 500nm TaCu layer is vapor-deposited on the titanium surface obtained in step (1);

[0074] (3) On the surface of the vapor-deposited layer in step (2), a 10nm Ta layer is vapor-deposited again, and the surface of the substrate obtains an antibacterial coating with good biocompatibility, and the anti-staphylococcus aureus effect is shown in Figure 3A and Figure 3B .

Embodiment 3

[0076] A composite coating with both antibacterial and biocompatibility, the preparation method of which is as follows:

[0077] (1) Use the polished titanium as the substrate, ultrasonically in deionized water, ethanol and acetone respectively for 30 minutes, and then use a nitrogen gun to clean the surface;

[0078] (2) Fix the cleaned titanium sheet on the evaporation plate, adopt electron beam evaporation method, TaCu 5 The alloy is used as the target material, the vacuum degree is 940Pa, and the coating rate is 0.12nm / min, and a 100nm TaCu layer is vapor-deposited on the titanium surface obtained in step (1);

[0079] (3) Evaporate a 40nm Ta layer on the surface of the vapor-deposited layer in step (2), and the substrate surface obtains an antibacterial coating with good biocompatibility, and the anti-staphylococcus aureus effect is shown in Figure 4A and Figure 4B .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com