Beneficiation method to increase production indexes of carbonaceous gold ore and reduce influence of production backwater upon production indexes

A technology of production index and beneficiation method, applied in flotation, solid separation and other directions, can solve the problems of large influence of flotation process and flotation index, high turbidity of production backwater, and inability to obtain results, so as to reduce influence and improve beneficiation index and the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

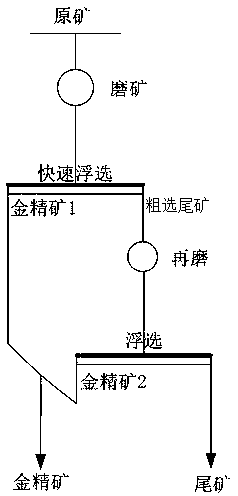

[0015] A carbon-bearing gold mine in Gansu, the gold grade is 5.43g / t, carbon-containing, low-sulfide carbonate-type gold ore, the concentration of the grinding slurry is 70%, and the ore is ground with production return water (solid content: 7%). Add sodium hydroxide in an amount of 2000g / t, water purifier MFA in an amount of 2000g / t, and the content of grinding fineness less than 0.044mm is 70%.

[0016] Adjust the concentration of the grinding pulp to 35%, add the activator copper sulfate, the dosage is 200g / t, add the collector butyl xanthate, the dosage is 500g / t, the foaming agent J-622, the dosage is 250g / t, the output Gold concentrate 1 and rougher tailings are produced.

[0017] Add water purifying agent MFA1000g / t to the roughing tailings, regrind fineness less than 0.044mm, the content is 95%, and the pulp concentration after regrinding is 50%

[0018] Adjust the concentration of regrinding pulp to 30%, add copper sulfate to 100g / t, butyl xanthate to 150g / t, and J-...

Embodiment 2

[0021] A carbon-bearing gold mine in Gansu, the gold grade is 5.65g / t, the concentration of the grinding slurry is 65%, the overflow of the thickener (solid content is 8.0%) is used for grinding, and the dosage of sodium hydroxide is 1500g / t. Water agent MFA, the dosage is 3000g / t, the grinding fineness is less than 0.044mm and the content is 65%.

[0022] Adjust the concentration of the grinding pulp to 35%, add the activator copper sulfate, the dosage is 200g / t, add the collector butyl xanthate, the dosage is 600g / t, the foaming agent J-622, the dosage is 280g / t, the output Gold concentrate 1 and rougher tailings are produced.

[0023] The water purifier MFA1200g / t is added to the roughing tailings, the regrinding fineness is less than 0.044mm, the content is 96%, and the pulp concentration after regrinding is 48%

[0024] Adjust the concentration of regrinding pulp to 33%, add copper sulfate to 150g / t, butyl xanthate to 180g / t, J-622 to 160g / t, carry out roughing and sweep...

Embodiment 3

[0027] A carbon-bearing gold mine in Xinjiang, the gold grade is 4.47g / t, which belongs to carbon-bearing gold ore, the concentration of the grinding slurry is 60%, the ore is ground with production return water (solid content is 6.5%), and sodium hydroxide is added, and the dosage is 2500g / t, water purifying agent MFA, the dosage is 1500g / t, the grinding fineness is less than 0.044mm and the content is 72%.

[0028] Adjust the concentration of the grinding pulp to 38%, add the activator copper sulfate, the dosage is 220g / t, add the collector butyl xanthate, the dosage is 400g / t, the foaming agent J-622, the dosage is 200g / t, the output Gold concentrate 1 and rougher tailings are produced.

[0029] The water purifier MFA800g / t is added to the roughing tailings, the regrinding fineness is less than 0.044mm, the content is 97%, and the pulp concentration after regrinding is 46%

[0030] Adjust the concentration of regrinding pulp to 35%, add copper sulfate to 80g / t, butyl xanth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com