A method for preparing graphene dendrites on an insulating substrate

A technology on an insulating substrate and an insulating substrate is applied in the field of microelectronic materials, which can solve problems such as pollution and damage, and achieve the effects of good repeatability, low cost of raw materials, and good deposition effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

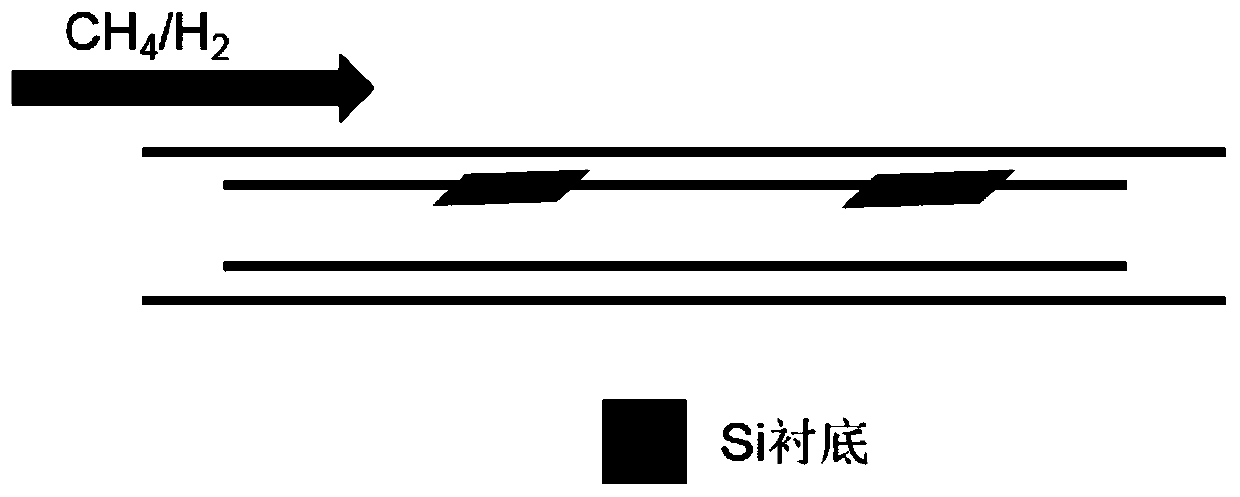

[0051] A method for preparing graphene dendrites on an insulating substrate, using SiO 2 / Si substrate as an example, including the following steps:

[0052] (1) SiO with a thickness of 500 μm 2 / Si substrate was ultrasonically cleaned and dried.

[0053] (2) Put the silicon substrate dried in (1) into the outer wall of the quartz inner tube in the CVD tube furnace, and the tube furnace is evacuated, and the vacuum pressure is 10 -5 mbar, raise the temperature to 300°C, the heating rate is 10°C / min, turn off the molecular pump; raise the temperature to 800°C, keep the temperature for 30 minutes, pass in hydrogen for hydrogen etching, the hydrogen flow rate is 15 sccm; slowly raise the temperature to 1050°C, the heating rate is 5°C / min, feed methane, the flow rate of methane is 30sccm, constant temperature 60min. Graphene dendrites can be obtained during the continuous decomposition and deposition of methane.

[0054] (3) After the growth is over, slide the tube furnace bo...

Embodiment 2

[0057] A method for preparing graphene dendrites on an insulating substrate, using SiO 2 / Si substrate as an example, including the following steps:

[0058] (1) SiO with a thickness of 500 μm 2 / Si substrate was ultrasonically cleaned and dried.

[0059] (2) Put the silicon substrate dried in (1) into the outer wall of the quartz inner tube in the CVD tube furnace, and the tube furnace is evacuated, and the vacuum pressure is 10 -5 mbar, raise the temperature to 300°C, the heating rate is 10°C / min, turn off the molecular pump; raise the temperature to 800°C, keep the temperature for 30 minutes, pass in hydrogen for hydrogen etching, the hydrogen flow rate is 25 sccm; slowly raise the temperature to 1050°C, the heating rate is 5°C / min, feed methane, the flow rate of methane is 15sccm, constant temperature 30min. Graphene dendrites can be obtained during the continuous decomposition and deposition of methane.

[0060] After the growth, slide the tube furnace box to cool do...

Embodiment 3

[0063] A method for preparing graphene dendrites on an insulating substrate, using SiO 2 / Si substrate as an example, including the following steps:

[0064] (1) SiO with a thickness of 500 μm 2 / Si substrate was ultrasonically cleaned and dried.

[0065] (2) Put the silicon substrate dried in (1) into the outer wall of the quartz inner tube in the CVD tube furnace, and the tube furnace is evacuated, and the vacuum pressure is 10 -5 mbar, raise the temperature to 300°C, the heating rate is 10°C / min, turn off the molecular pump; raise the temperature to 800°C, keep the temperature for 30 minutes, pass in hydrogen for hydrogen etching, the hydrogen flow rate is 15 sccm; slowly raise the temperature to 1050°C, the heating rate is 5°C / min, feed methane, the flow rate of methane is 25sccm, constant temperature 120min. Graphene dendrites can be obtained during the continuous decomposition and deposition of methane.

[0066] (3) After the growth is over, slide the tube furnace b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com