Special reinforcing agent for permeable concrete and preparation method thereof

A permeable concrete and reinforcing agent technology, applied in the field of building materials, can solve the problems of unsuitable permeable concrete, lower water permeability coefficient, poor water permeability, etc., and achieve good adhesion, improved anti-knock ability, and high bonding ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

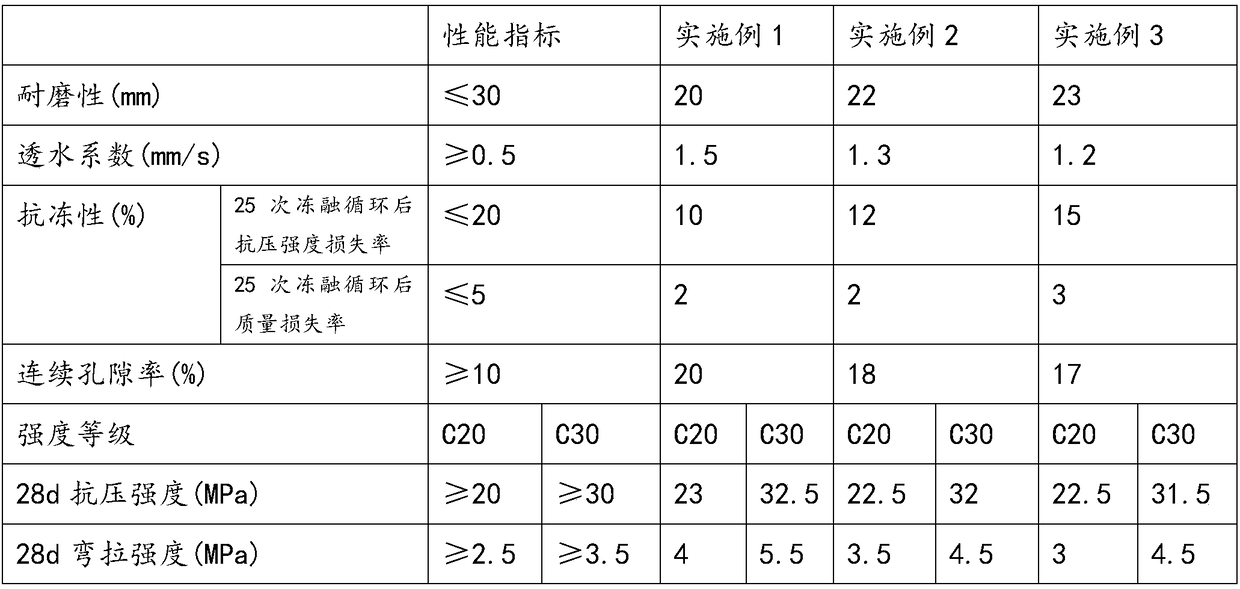

Examples

Embodiment 1

[0025] A preparation method of a special reinforcing agent for permeable concrete, the steps are as follows: firstly, 35 parts of vinyl acetate and ethylene copolymerized rubber powder and 1.5 parts of PVA1799 are weighed into a mixer and mixed evenly, and then 1.5 parts of polypropylene fibers with a length of 10 mm are added. , 47 parts of micro-silica powder were added to the mixer in turn and mixed evenly, and finally 15 parts of polycarboxylate water reducing agent were added and mixed evenly to obtain the special reinforcing agent for permeable concrete.

Embodiment 2

[0027] A preparation method of a special reinforcing agent for permeable concrete, the steps are as follows: firstly, 38 parts of acrylate and styrene copolymerized rubber powder and 1 part of PVA1799 are weighed into a mixer and mixed evenly, and then 1 part of polypropylene fiber with a length of 10mm is added. , 45 microsilica fume is added to the mixer in turn to mix evenly, and finally 15 parts of polycarboxylate water reducer is added to mix evenly, that is, the special reinforcing agent for permeable concrete is obtained.

Embodiment 3

[0029] A preparation method of a special reinforcing agent for permeable concrete, the steps are as follows: firstly, 31 parts of vinyl acetate / ethylene tertiary carbonate copolymerized rubber powder and 2 parts of PVA1788 are weighed into a mixer and mixed evenly, and then 2 parts of polypropylene fibers with a length of 10 mm are weighed. 50 parts of microsilica powder were added to the mixer in turn to mix evenly, and finally 15 parts of sulfamate water-reducing agent were added to mix evenly to obtain the special reinforcing agent for permeable concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com