Process for producing acetate from p-toluene sulfonic acid

A technology of p-toluenesulfonic acid and acetate, which is applied in the preparation of carboxylic acid esters, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of acid corrosion, low catalytic reaction temperature and high catalytic activity temperature, and achieve less loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Sulfuric acid and p-toluenesulfonic acid were tested for comparison.

[0026] Select 2g of sulfuric acid and 4g of p-toluenesulfonic acid as catalysts respectively, and configure them into 30% aqueous solution through the first and second steps in the above method. The concentration of hydrogen ions in the aqueous solution is about 0.04mol, and the concentration of the catalyst Basically the same.

[0027] Then use the third step and the fourth step in the above method to carry out catalytic reaction, then continue to add acetic acid and n-propanol (n-butanol) reaction mixture, and finally get 2 kg of acetic acid ester crude ester material containing about 86%, stop The results after the reaction are detected as shown in Table 1:

[0028] catalyst

Acetate content

unknown content

Waste liquid volume

Kettle liquid condition

sulfuric acid

85.69%

3.6%

100mL

black sticky

p-toluenesulfonic acid

86.11%

0.17%

5mL ...

Embodiment 2

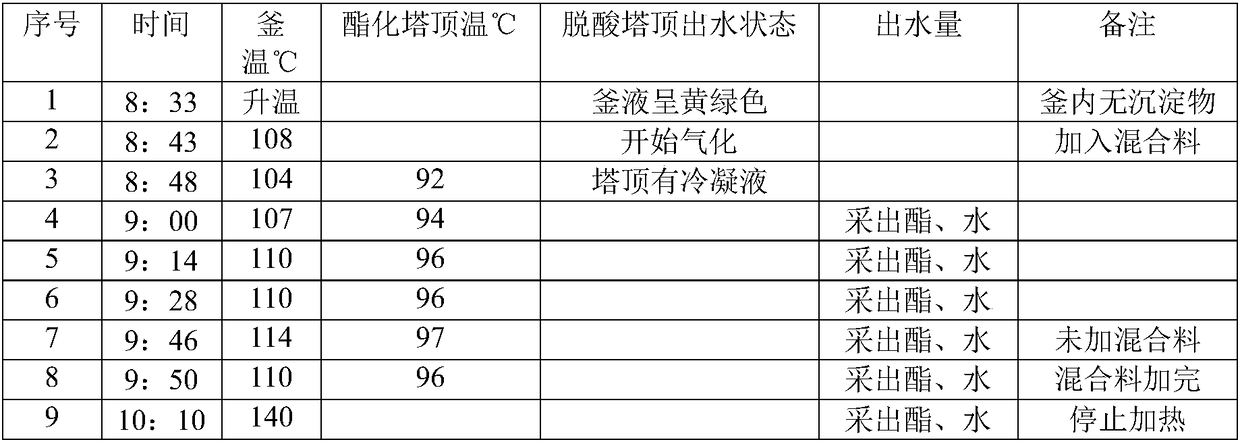

[0032] P-toluenesulfonic acid is 1% to catalyze the production process of esterification propyl acetate as shown in table 2-3:

[0033] serial number

[0034] serial number

[0035] It can be seen from the above table that when p-toluenesulfonic acid is used as a catalyst for the catalytic reaction, the water separation is close to the theoretical production amount of 60mL, and the reaction effect is excellent.

Embodiment 3

[0037] The production process of p-toluenesulfonic acid catalyzed esterification to produce n-butyl propionate is shown in table 4-5:

[0038] serial number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com