Application of a mononuclear nickel complex containing mnt ligand as a catalyst for electrocatalytic hydrogen production

A nickel complex, electrocatalysis technology, applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, nickel organic compound, etc., can solve the problem of less research on catalytic hydrogen production performance, achieve synthesis The method is simple, the synthesis yield is high, and the reaction conditions are mild.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

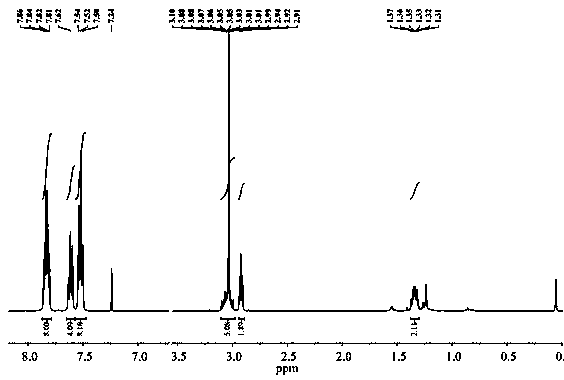

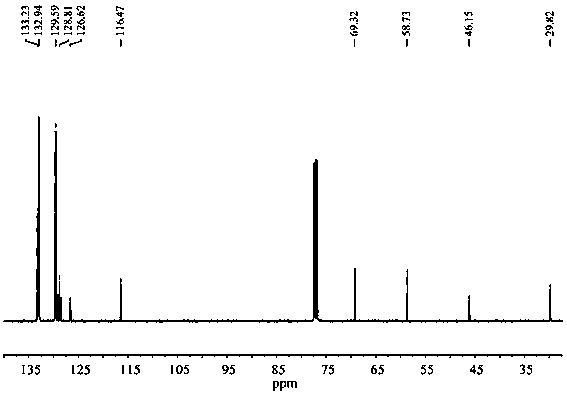

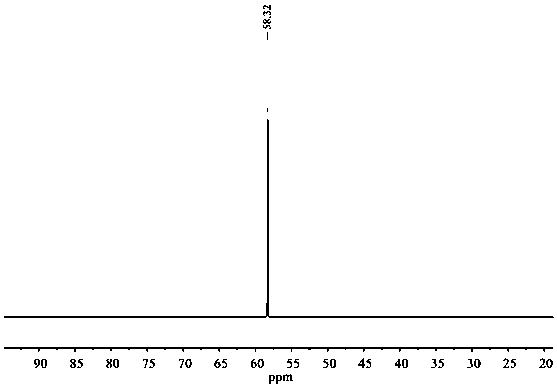

[0029] A kind of mononuclear nickel complex containing N-substituted bis (diphenylphosphino) ammonia and maleonitrile dithiolate ligand, the chemical formula of the mononuclear nickel complex is (CH 3 O(CH 2 ) 3 N(PPh 2 ) 2 )Ni(mnt), the reaction equation is as follows:

[0030]

[0031] The synthetic method of described mononuclear nickel complex containing N-substituted bis(diphenylphosphino)ammonia and maleonitrile dithiolate ligand is as follows:

[0032] In a round bottom flask equipped with a magnetic stir bar, 0.1860 g Na 2 mnt (1mmol), 0.5870g (CH 3 O(CH 2 ) 3 N(PPh 2 ) 2 )NiCl 2 (1mmol) and 20mL of dichloromethane were mixed, stirred and reacted at room temperature for 3 hours to obtain an orange-red solution. Wash with 2 x 20 mL water to remove NaCl, anhydrous MgSO 4 Drying, rotary evaporator decompression removes organic solvent, dissolves with appropriate amount of dichloromethane, uses the dichloromethane:methanol that volume ratio is 10:1 to carry ...

Embodiment 2

[0034] A kind of mononuclear nickel complex containing N-substituted bis (diphenylphosphino) ammonia and maleonitrile dithiolate ligand, the chemical formula of the mononuclear nickel complex is (CH 3 S(CH 2 ) 3 N(PPh 2 ) 2 )Ni(mnt), its chemical structure is as follows:

[0035]

[0036] The synthetic method of described mononuclear nickel complex containing N-substituted bis(diphenylphosphino)ammonia and maleonitrile dithiolate ligand is as follows:

[0037] In a round bottom flask equipped with a magnetic stir bar, 0.1860 g Na 2 mnt (1mmol), 0.6030g (CH 3 S(CH 2 ) 3 N(PPh 2 ) 2 )NiCl 2 (1mmol) and 20mL of dichloromethane were mixed, stirred and reacted at room temperature for 3 hours to obtain an orange-red solution. Wash with 2 x 20 mL water to remove NaCl, anhydrous MgSO 4 Dry, remove the organic solvent under reduced pressure with a rotary evaporator, dissolve with an appropriate amount of dichloromethane, use a 20:1 mixture of dichloromethane and methanol...

Embodiment 3

[0039] A kind of mononuclear nickel complex containing N-substituted bis (diphenylphosphino) ammonia and maleonitrile dithiolate ligand, the chemical formula of the mononuclear nickel complex is (CH 3 CHPhN (PPh 2 ) 2 )Ni(mnt), its chemical structure is as follows:

[0040]

[0041] The synthetic method of described mononuclear nickel complex containing N-substituted bis(diphenylphosphino)ammonia and maleonitrile dithiolate ligand is as follows:

[0042] In a round bottom flask equipped with a magnetic stir bar, 0.1860 g Na 2 mnt (1mmol), 0.6190g (CH 3 CHPhN (PPh 2 ) 2 )NiCl 2 (1 mmol) and 20 mL of chloroform were mixed, stirred and reacted at room temperature for 3 hours to obtain an orange-red solution. Wash with 2 x 20 mL water to remove NaCl, anhydrous MgSO 4 Dry, remove the organic solvent under reduced pressure with a rotary evaporator, dissolve with an appropriate amount of dichloromethane, use a 10:1 mixture of dichloromethane and methanol as a developing so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com